How to design an energy storage cabinet: integration and

As the core equipment in the energy storage system, the energy storage cabinet plays a key role in storing, dispatching and releasing electrical energy. How to design an

Get Price

Energy storage technology service cabinet

This production line is used for automatic assembly of energy storage cabinets. All single machine equipment and distributed systems interact with MES through a scheduling system, achieving

Get Price

Why Use High Voltage Energy Storage Cabinets? 7 Powerful

Why Your Energy Strategy Needs Steroids Let''s cut through the technical jargon. High voltage systems (typically 1,000V or higher) act like energy magnifying glasses,

Get Price

Energy storage high voltage cabinet structure

It can be seen from Figure 1 that in the energy storage system, the prefabricated cabin is the carrier of the energy storage devices, the most basic component of the energy storage

Get Price

Assembly and Binding of Energy Storage Cabinet: A Step-by

If you''re an energy project manager, installation technician, or sustainability-focused engineer, you''ve probably faced the "Transformer Dilemma" – how to efficiently assemble bulky energy

Get Price

Battery Energy Storage Cabinet Construction Process: From

Let''s be real - when most people hear "battery energy storage cabinet construction process," they picture workers bolting together metal panels like IKEA furniture on steroids. But here''s the

Get Price

How to Operate High Voltage Energy Storage Systems: A Step

Ever wondered why high voltage energy storage systems are like the Swiss Army knives of modern power grids? These systems—operating at 1,000V or higher—are

Get Price

(PDF) BATTERY MODULE AND PACK ASSEMBLY PROCESS

Abstract Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and battery pack assembly.

Get Price

BATTERY ENERGY STORAGE SYSTEMS (BESS)

We also provide customized connection solutions for charging stations, high-voltage control cabinets, and energy-storage and communication power supplies. At TE, we are dedicated to

Get Price

Cabinet design and EMC

EMC-compliant design and control cabinet configuration For detailed configuration instructions regarding the EMC-compliant design of drives and control cabinet configuration, refer to the

Get Price

The BESS System: Construction, Commissioning, and O&M Guide

A comprehensive guide on the construction, commissioning, and operation & maintenance of industrial and commercial energy storage systems.

Get Price

Energy storage cabinet installation process

Further, the installation process and process guidance for the energy storage prefabricated module are developed to ensure the safe handover of the energy storage system.

Get Price

Smart Energy Storage Cabinet Assembly Line-Battery PACK

SHINHOP Laser Intelligent Energy Storage Cabinet Assembly Line The process flow includes: feeding, OCV sorting, gluing, tightening, AI polarity detection and pole addressing, pole

Get Price

Bcp system energy storage combiner cabinet

Outdoor liquid cooled and air cooled cabinets can be paired together utilizing a high voltage/current battery combiner box. Outdoor cabinets are manufactured to be a install ready

Get Price

Energy storage operation of high voltage incoming cabinet

The invention discloses a high-voltage cascade energy storage device which comprises a high-voltage switch station cabinet, an incoming line cabinet, a starting cabinet, a reactance

Get Price

BATTERY ENERGY STORAGE SYSTEMS

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this

Get Price

Operation of Energy Storage Battery Cabinets on the Grid Side

Energy storage battery cabinets are integral components of energy storage systems. Their operation on the grid side involves energy charge/discharge management,

Get Price

High Voltage Cabinet and PLC: The Dynamic Duo Powering Energy Storage

Ever wondered what keeps energy storage systems from going full "Frankenstein''s monster" during power surges? Meet the unsung heroes: high voltage cabinets, PLCs, and their dance

Get Price

Unlocking the Power of High-Voltage Energy Storage Cabinets:

Why High-Voltage Energy Storage Cabinets Are Stealing the Spotlight California''s grid operator suddenly faces a 10% surge in electricity demand during a heatwave. Instead of firing up fossil

Get Price

Wholesale High-voltage Energy Storage Cabinets,OEM/ODM High-voltage

Light Board Wiring Harness Is New Energy Wiring Harness This product is used for charging piles, high-voltage energy storage cabinets, balcony energy storage power supplies, home

Get Price

Introduction to the high-voltage manufacturing process

Explore the high-voltage manufacturing process and discover how innovative ideas become real. Learn more in our latest blog post.

Get Price

High Voltage Battery Cabinet: Revolutionizing Energy Storage

The true performance of a High Voltage Battery Cabinet lies in its internal engineering and meticulous assembly. The advanced rack systems offered by Hicorenergy

Get Price

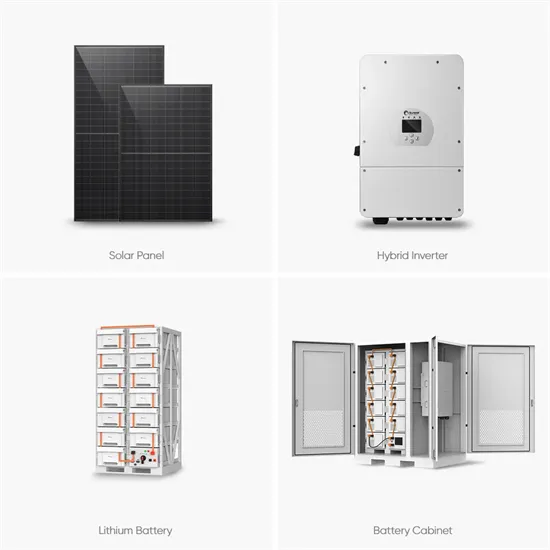

The Architecture of Battery Energy Storage Systems

Before discussing battery energy storage system (BESS) architecture and battery types, we must first focus on the most common

Get Price

Installation process-SEPLOS 145KWH high voltage energy storage cabinet

This video is about the SEPLOS 145KWH lithium-ion high-voltage cabinet battery system.

Get Price

6 FAQs about [Communication high-voltage energy storage cabinet assembly plan and process]

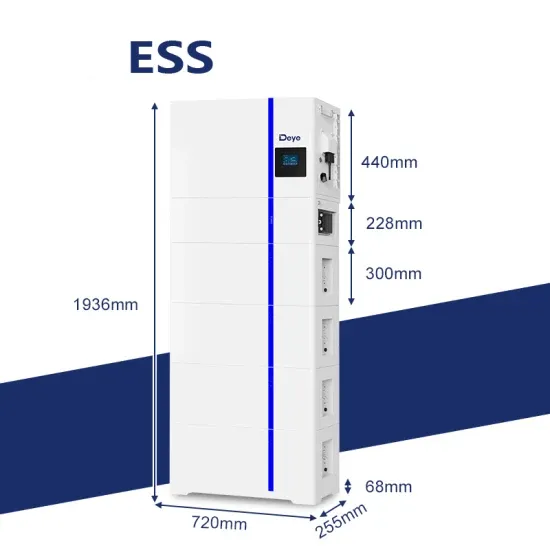

What is energy storage cabinet?

Energy Storage Cabinet is a vital part of modern energy management system, especially when storing and dispatching energy between renewable energy (such as solar energy and wind energy) and power grid. As the global demand for clean energy increases, the design and optimization of energy storage sys

What is a battery energy storage system (BESS) e-book?

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this document comes from Sinovoltaics’ own BESS project experience and industry best practices.

What are the sections of energy storage project guide?

The guide is divided into three main sections: construction and installation, commissioning, and operation & maintenance. It covers various aspects such as foundation construction, battery and inverter installation, wiring, system testing, monitoring, fault handling, and preventive maintenance. 1. Energy Storage Project Construction 2.

What are the steps in energy storage installation?

The main steps are: to build the foundation, install the energy storage cabinets, install the battery and inverter, and wire it all. During the commissioning of an energy storage system, which tests does the team perform? System-wide joint commissioning.

How to install a containerized energy storage system?

Use an insulating heat-shrinkable tube for secure terminal fit and label wires clearly. Clean up any foreign objects in the distribution cabinet. Connect all metal shells within the energy storage box to form a grounding network using good conductors or dedicated grounding strips. 6. Containerized Energy Storage System Installation Complete

Why do energy storage cabinets use STS?

STS can complete power switching within milliseconds to ensure the continuity and reliability of power supply. In the design of energy storage cabinets, STS is usually used in the following scenarios: Power switching: When the power grid loses power or fails, quickly switch to the energy storage system to provide power.

More related information

-

What is the power supply of the communication high-voltage energy storage cabinet

What is the power supply of the communication high-voltage energy storage cabinet

-

Energy storage cabinet assembly process station

Energy storage cabinet assembly process station

-

Battery Energy Storage Cabinet Cost Plan and Process

Battery Energy Storage Cabinet Cost Plan and Process

-

Communication high-voltage energy storage battery cabinet energy storage principle

Communication high-voltage energy storage battery cabinet energy storage principle

-

Communication base station inverter energy storage cabinet analyzer

Communication base station inverter energy storage cabinet analyzer

-

Base station communication energy storage cabinet outdoor site

Base station communication energy storage cabinet outdoor site

-

Energy Storage Container Assembly Process

Energy Storage Container Assembly Process

-

Communication Energy Storage Cabinet Base Station

Communication Energy Storage Cabinet Base Station

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.