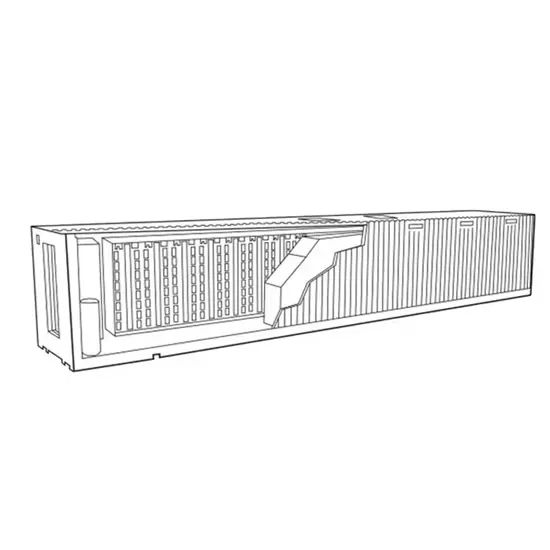

Energy storage container battery assembly sequence

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage

Get Price

Energy Storage Liquid-Cooled Energy Storage Battery and Pack Assembly

The Energy Storage Liquid-Cooled Energy Storage Battery and Pack Assembly Production Line Self-Developed by UW Laser Contact us for more details if you are interested!

Get Price

Premium BESS Container Manufacturing & Global

TLS Energy International engineers, fabricates, and ships custom Battery Energy Storage System (BESS) containers worldwide, backed by

Get Price

Container Type Energy Storage System Assembly

The assembly solution for container type energy storage system integrates the assembly line, the heavy load handling system and the

Get Price

Assembly Line for Battery Energy Storage System (BESS)

This solution caters to the growing demand for large-scale energy storage solutions for renewable energy, grid stabilization, and backup power systems. Maestrotech''s BESS assembly lines

Get Price

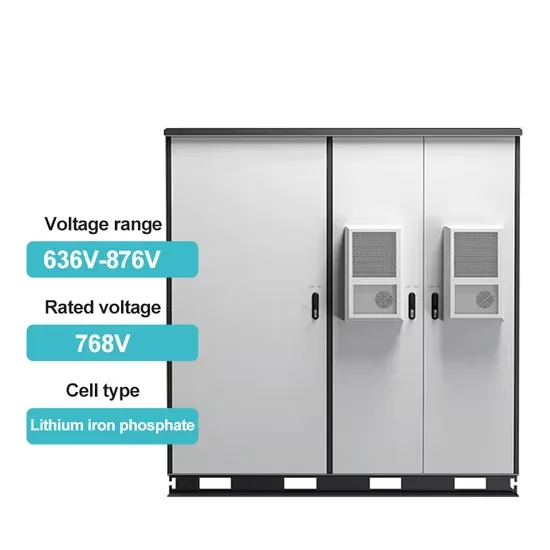

Understanding Battery Pack Technology: Key

Battery pack technology is a sophisticated system integrating battery cells, a battery management system (BMS), structural components, and thermal management

Get Price

Energy storage containers Manufacturer | Ultramodulaa

Energy storage container Production and assembly We are an experienced manufacturer containers energy storage, offering comprehensive service from

Get Price

Intensium Energy Storage Systems | Saft | Batteries

The Intensium® ranges are standardized to deliver a consistent and holistic design that scales up to multi-megawatt systems and are ready to plug and

Get Price

Container Type Energy Storage System Assembly Line

The assembly solution for container type energy storage system integrates the assembly line, the heavy load handling system and the warehousing system, and the process flow of...

Get Price

THE INGENIOUS MANUFACTURE PROCESS OF

This article delves into the innovative manufacturing process behind TLS Offshore Containers'' BESS containers, shedding light on the key

Get Price

Energy Storage Container Assembly Process Video: Your Visual

As global battery storage capacity is projected to reach 1.6 TWh by 2030 [1], manufacturers are racing to optimize production. These videos aren''t just factory floor recordings – they''re

Get Price

BESS Assemblies: A Comprehensive Guide to the Complex Process

BESS stands for state-of-the-art energy storage systems and makes a very basic contribution to the integration of renewable energy sources and the stabilization of the grid. A BESS is

Get Price

Energy storage container system assembly process

Energy Storage Container is an energy storage battery system, which includes a monitoring system, battery management unit, particular fire protection system, special air conditioner,

Get Price

Battery Pack Assembly Process Series 9

June 12, 2025 Battery Pack Assembly Process Series 9 - Basic Knowledge of Energy Storage Containers Battery energy storage systems are mainly divided into: container energy storage,

Get Price

Utility-scale battery energy storage system (BESS)

Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and conversion – and

Get Price

THE INGENIOUS MANUFACTURE PROCESS OF TLS OFFSHORE CONTAINERS

This article delves into the innovative manufacturing process behind TLS Offshore Containers'' BESS containers, shedding light on the key features and benefits that make them

Get Price

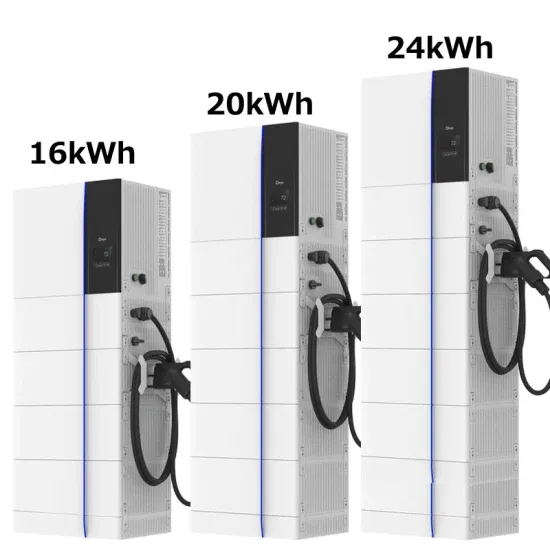

Battery Pack Assembly Process Series 9

Battery energy storage systems are mainly divided into: container energy storage, industrial and commercial energy storage, household energy storage and portable energy

Get Price

What the process of assembly of industrial energy storage looks

In this article, we will provide a step-by-step overview of the process of implementing an industrial energy storage system, what formalities need to be fulfilled and what to pay special attention

Get Price

The Art and Science of Energy Storage Equipment Assembly: A

Let''s face it – when most people hear "energy storage equipment assembly," they imagine technicians casually snapping battery modules together like LEGO bricks.

Get Price

Energy storage container assembly line process standards

Energy storage containers are designed to store energy from wind turbines, photovoltaics, etc. These are made from rugged and robust construction in overall structures.

Get Price

Understanding the Battery Cell Assembly Process

The battery cell assembly process must continue to evolve to ensure that it remains a reliable, efficient, and sustainable method of storing energy. In the next section, we

Get Price

Mastering the Battery Pack Assembly Process: A

Conclusion The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy

Get Price

The Assembly Process of 20ft Energy Storage

At TLS Offshore Containers, we follow a rigorous and systematic approach to the assembly of our energy storage containers, ensuring they

Get Price

Making 2D Materials Sparkle in Energy Storage via Assembly

ConspectusTwo-dimensional (2D) materials such as graphene and MXenes offer appealing opportunities in electrochemical energy storage due to their large surface area,

Get Price

The Assembly Process of 20ft Energy Storage Containers by TLS

At TLS Offshore Containers, we follow a rigorous and systematic approach to the assembly of our energy storage containers, ensuring they meet the highest industry standards

Get Price

Energy Storage System Module and Pack Production Line

Founded in 2010, Wuxi Autowell Technology Co., Ltd. (ATW) is a well-known intelligent equipment manufacturer in the photovoltaic and lithium-ion battery industries, and currently has more than

Get Price

More related information

-

Energy Storage Container Assembly Process

Energy Storage Container Assembly Process

-

The whole process of energy storage container processing

The whole process of energy storage container processing

-

Installation process inside the energy storage container at the site

Installation process inside the energy storage container at the site

-

Energy storage container assembly and installation

Energy storage container assembly and installation

-

Energy Storage Container Solar Monocrystalline Battery Business Unit Process

Energy Storage Container Solar Monocrystalline Battery Business Unit Process

-

Energy storage container assembly automation equipment

Energy storage container assembly automation equipment

-

Communication high-voltage energy storage cabinet assembly plan and process

Communication high-voltage energy storage cabinet assembly plan and process

-

Energy Storage Container Development Process

Energy Storage Container Development Process

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.