Li-Ion Battery Safe Temperature: Everything You Should Know

Discover safe lithium-ion battery temperature limits for charging, storage, and cold weather performance.

Get Price

Understanding Lithium-Ion Battery Temperature

Lithium-ion batteries have become a cornerstone of modern technology, powering everything from smartphones to electric vehicles.

Get Price

Effects of Temperature Differences Among Cells on the

This work aims to make a comparative analysis of the unbalanced discharging phenomenon for battery packs with series/parallel configurations due to the temperature

Get Price

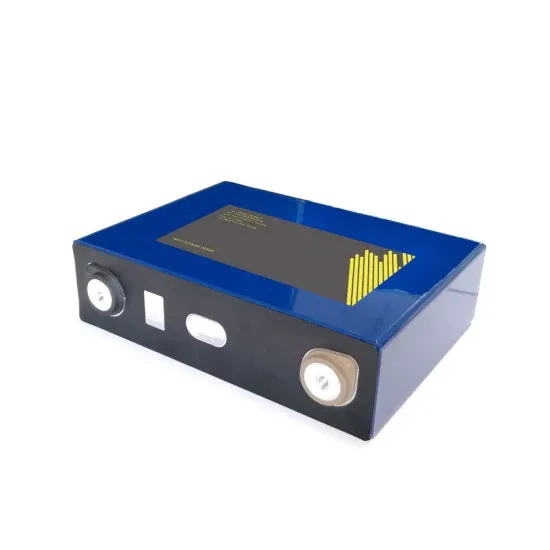

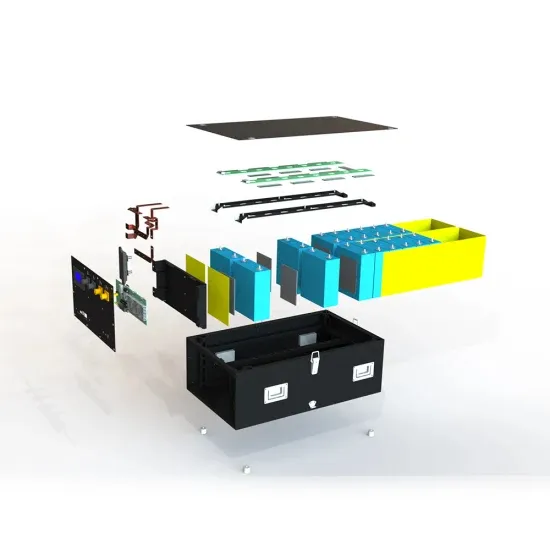

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs and energy storage.

Get Price

Unbalanced discharging and aging due to temperature differences

Request PDF | Unbalanced discharging and aging due to temperature differences among the cells in a lithium-ion battery pack with parallel combination | This paper presents an

Get Price

Unbalanced discharging and aging due to temperature differences

A thermal–electrochemical model is developed for the parallel-connected battery pack. The effects of temperature difference on the unbalanced discharging performances are

Get Price

Optimization of liquid cooling and heat dissipation system of lithium

The results show that the maximum temperature difference of the optimized scheme is reduced by 7.49% compared with the initial scheme, and the temperature field distribution of

Get Price

Temperature-considered active balancing strategy for lithium-ion

Battery balancing plays a crucial role in improving the overall performance and lifespan of battery packs. However, most balancing strategies only pursue balancing speed

Get Price

A Guide to Lithium Battery Temperature Ranges for

For storage, it is best to keep them in a temperature range of -20°C to 25°C (-4°F to 77°F). Extreme temperatures can significantly affect

Get Price

Effects of Temperature Differences Among Cells on

This work aims to make a comparative analysis of the unbalanced discharging phenomenon for battery packs with series/parallel configurations

Get Price

Temperature distribution of lithium ion battery module with

The above analysis indicates that the temperature difference will be greatly suppressed and keeps stable for inconsistent battery cells under bidirectional pulsed current

Get Price

Degradation in parallel-connected lithium-ion battery packs

Practical lithium-ion battery systems require parallelisation of tens to hundreds of cells, however understanding of how pack-level thermal gradients influence lifetime perfor-mance remains...

Get Price

The Definitive Guide to Lithium Battery Temperature Range

Lithium batteries have transformed portable electronics and renewable energy storage with their compact size, high energy density, and long lifespan. Temperature greatly affects their

Get Price

Internal thermal network model-based inner temperature

The lithium-ion battery pack is manufactured that many cells are connected in parallel or series to suit the purpose of use. Thus, the characteristics of the cells determine the

Get Price

Battery pack temperature, the maximal difference in temperature

Although the temperature difference reaches more than 10 °C at the initial moment, the temperature difference at the end of the preheating is controlled to be around 6 °C, which

Get Price

A Guide to Lithium Battery Temperature Ranges for Optimal

For storage, it is best to keep them in a temperature range of -20°C to 25°C (-4°F to 77°F). Extreme temperatures can significantly affect performance, safety, and lifespan. This

Get Price

Unbalanced discharging and aging due to temperature

A thermal–electrochemical model is developed for the parallel-connected battery pack. The effects of temperature difference on the unbalanced discharging performances are

Get Price

A closed-loop control on temperature difference of a lithium-ion

In this work, we established a three-dimensional heat transfer model and investigated the evolution of temperature uniformity within the self-heating lithium-ion battery

Get Price

Study on the impact of battery pack arrangement on temperature

Lithium-ion batteries are widely used in portable electronic devices and electric vehicles. However, the thermal performance of lithium-ion batteries is a major concern, as

Get Price

Temperature effects on battery performance explained

Temperature imbalances can cause uneven aging and degradation within a battery pack. Lithium-ion batteries degrade over time, and temperature plays a crucial role in this

Get Price

Determination of Internal Temperature Differences for Various

Surface-mounted temperature sensors, such as thermistors or thermocouples, are a common method to measure the temperature of LIBs within a battery pack.

Get Price

Temperature effects on battery performance explained

Temperature imbalances can cause uneven aging and degradation within a battery pack. Lithium-ion batteries degrade over time, and

Get Price

Simulation and analysis of air cooling configurations for a lithium

Lithium-ion batteries are widely used in electric vehicles (EVs) and hybrid electric vehicles (HEVs), in which proper measures have to be taken to ensure the batteries working

Get Price

Analysis of the Thermal Conditions in a Lithium-Ion Battery Pack

Thermal resistance between Li-ion battery and the battery pack case was found to greatly reduce heat exchange with the environment. The temperature difference across the

Get Price

Review on Battery Packing Design Strategies for

An optimal battery packing design can maintain the battery cell temperature at the most favorable range, i.e., 25–40 °C, with a temperature

Get Price

Lithium Batteries Discharging at High and Low Temperatures

When you operate a lithium ion battery pack at high temperatures, you see immediate changes in battery performance and long-term effects on battery life. Discharging at

Get Price

Research on the heat dissipation performances of lithium-ion battery

Lithium-ion power batteries have become integral to the advancement of new energy vehicles. However, their performance is notably compromised by excessive

Get Price

6 FAQs about [Lithium battery pack temperature difference]

What is the temperature difference between cells in a battery pack?

The temperature differences among cells in a battery pack must be well controlled (≤5 °C) to minimize the unbalanced discharging and aging between cells. This is especially important as the ambient temperature increases.

Does a lithium ion battery reduce heat exchange?

Thermal resistance between Li-ion battery and the battery pack case was found to greatly reduce heat exchange with the environment. The temperature difference across the battery pack in a practically significant range of variables was from 2 to 16°С.

How does temperature affect the internal resistance of a battery pack?

Temperature differences among the cells in a battery pack can lead to significant differences in internal resistance. The passage mentions that the larger the temperature differences, the more the difference in internal resistance between cells. However, the total internal resistance of the battery pack changes little, with a 10 °C temperature difference resulting in approximately 10% lower total internal resistance compared to 5 °C.

How does ambient temperature affect lithium battery heat exchange?

Thus, it can be concluded that in the natural convection mode with heat exchange rate close to maximum possible (α = 10 W m –1 K –1), elevated ambient temperature creates conditions for thermal runaway of the lithium battery due to its thermal resistance (technological air gap) that reduces the battery heat exchange with the environment. Fig. 8.

How important is the internal temperature of lithium-ion batteries?

Author to whom correspondence should be addressed. The temperature of lithium-ion batteries is crucial in terms of performance, aging, and safety. The internal temperature, which is complicated to measure with conventional temperature sensors, plays an important role here.

Does temperature control prevent thermal runaway of lithium ion batteries?

Therefore, considering the narrow recommended operating range , for example, of lithium-ion batteries (25 to 40°C) and the exponential dependence on temperature of the rates of physical and chemical processes in chemical current sources, the temperature control on the external surface of a battery will not prevent its thermal runaway.

More related information

-

The voltage difference between each string of lithium battery pack

The voltage difference between each string of lithium battery pack

-

Lifespan of high temperature lithium battery pack

Lifespan of high temperature lithium battery pack

-

126590 Dual lithium battery pack

126590 Dual lithium battery pack

-

Pack lithium battery quality control points

Pack lithium battery quality control points

-

Botswana regular lithium battery pack factory price

Botswana regular lithium battery pack factory price

-

How many strings are there for a 72v 60ah lithium battery pack in the Netherlands

How many strings are there for a 72v 60ah lithium battery pack in the Netherlands

-

Ireland 24v lithium battery pack

Ireland 24v lithium battery pack

-

Thailand new energy lithium battery pack

Thailand new energy lithium battery pack

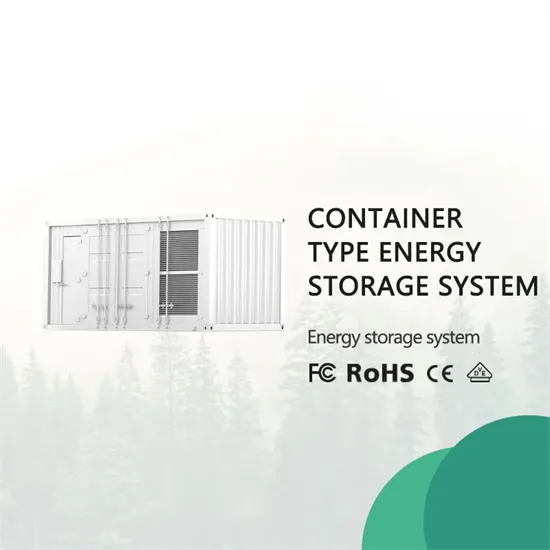

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.