Quality Management for Battery Production: A Quality Gate Concept

In order to reduce costs and improve the quality of lithium-ion batteries, a comprehensive quality management concept is proposed in this paper. Goal is the definition of

Get Price

Lithium-ion Battery Pack Manufacturing Process & Design

Strict quality control protocols are crucial throughout the entire lithium-ion battery manufacturing process. From the procurement of battery cells, battery PCBs, BMS, and other

Get Price

Quality control in lithium-ion battery PACK production: A critical

QC is an essential part of lithium-ion battery PACK production. By implementing effective QC procedures, manufacturers can help to ensure the quality and safety of their

Get Price

Best practices in Li-ion cell quality control and battery

What are the best practices for battery pack manufacturing that you follow? There are four broad facets to be considered while designing a

Get Price

Quality control in lithium-ion battery PACK production:

QC is an essential part of lithium-ion battery PACK production. By implementing effective QC procedures, manufacturers can help to ensure the

Get Price

Battery Module & Pack Manufacturing: Step-by-Step

Turnkey lines now include real-time quality monitoring — from cell sorting to final testing — using high-resolution CCD cameras, inline impedance testers, and AI-driven defect

Get Price

Basics of battery management system (BMS), battery pack

Quality control is crucial to ensure that battery packs are safe, reliable, and effective. Several quality control points must be adhered to during the manufacturing process:

Get Price

9 Steps to Know How a Battery Pack Is Made

High-quality lithium-ion cells, connectors, and Battery Management System (BMS) components are essential for ensuring the pack''s performance, safety,

Get Price

Challenges and opportunities for high-quality battery

The rise in battery production faces challenges from manufacturing complexity and sensitivity, causing safety and reliability issues. This

Get Price

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get Price

Lithium Ion Battery Pack Testing

We offer various quality control solutions for lithium batteries, ranging from small cells (3.7V) to large battery packs for EV trucks (up to 1000 V). The subsequent graph

Get Price

The Critical Role of Moisture Analysis in Lithium-Ion

Quantify and control moisture to prevent defects, enhance performance, and ensure safety in lithium-ion battery production and

Get Price

Understanding the Lithium-Ion Battery Manufacturing Process

Intro Creating a lithium-ion battery is like piecing together a complex puzzle where every part plays a crucial role in achieving the final goal. These batteries, which power everything from

Get Price

QUALITY CONTROL IN THE PRODUCTION OF

In addition to a comprehensive range of products and applications dedicated to process control, Marposs also provides dedicated solutions for laboratory analysis and control.

Get Price

Battery Manufacturing Process: Materials, Production

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Price

Battery Quality at Scale

Battery quality is among the most difficult issues facing the industry today due to the complexity of both battery failure and gigawatt-hour-scale

Get Price

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Get Price

Evaluating the Manufacturing Quality of Lithium Ion Pouch Batteries

Lithium-ion batteries must undergo a series of quality control tests before being approved for sale. In this study, quality control tests were carried out on two types of lithium

Get Price

Battery Research and Manufacturing | Battery Quality Control

Quality control and quality assurance in battery research and manufacturing relies on a range of analytical techniques including electron microscopy and spectroscopy.

Get Price

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get Price

Lithium Ion Battery Quality Control | Lithium-Ion

Quality Assurance When Procuring Lithium Ion Battery Systems,High standard quality management for battery production,JB Battery always offering good

Get Price

Battery Module & Pack Manufacturing: Step-by-Step

Turnkey lines now include real-time quality monitoring — from cell sorting to final testing — using high-resolution CCD cameras, inline

Get Price

Inside a Battery Factory: How Lithium-ion PACK Lines

The lithium battery module PACK production line is a complex system project involving multiple links and aspects of management and

Get Price

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get Price

Best practices in Li-ion cell quality control and battery pack

What are the best practices for battery pack manufacturing that you follow? There are four broad facets to be considered while designing a battery pack. Mechanical design –

Get Price

Barry on Batteries: Inside the Quality Control Lab of Lithium-Ion

Explore the complexities of battery cell testing and the rigorous standards that must be applied to the process. Lithium-ion battery quality control (QC) shares parallels with

Get Price

What is the packaging technology of soft pack Li Ion

Soft pack lithium-ion batteries are always found in consumer electronics, as UAV/drone batteries, and the high-performance batteries of

Get Price

Lithium Ion Battery Pack Testing

We offer various quality control solutions for lithium batteries, ranging from small cells (3.7V) to large battery packs for EV trucks (up to 1000

Get Price

More related information

-

Which Dutch lithium battery pack has good quality

Which Dutch lithium battery pack has good quality

-

Turkmenistan large-cell lithium battery pack

Turkmenistan large-cell lithium battery pack

-

Can I use a 48v lithium battery pack if one is missing

Can I use a 48v lithium battery pack if one is missing

-

25 2v 2a lithium battery pack

25 2v 2a lithium battery pack

-

Lithium battery pack base

Lithium battery pack base

-

Laos lithium battery pack

Laos lithium battery pack

-

Cameroon special solar lithium battery pack

Cameroon special solar lithium battery pack

-

Colombia 40kwh lithium battery pack

Colombia 40kwh lithium battery pack

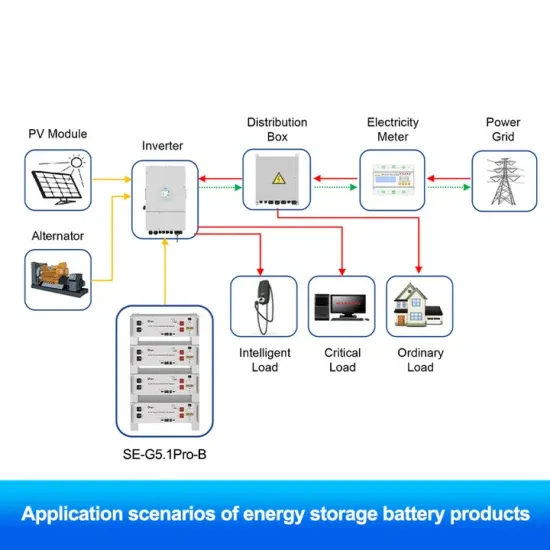

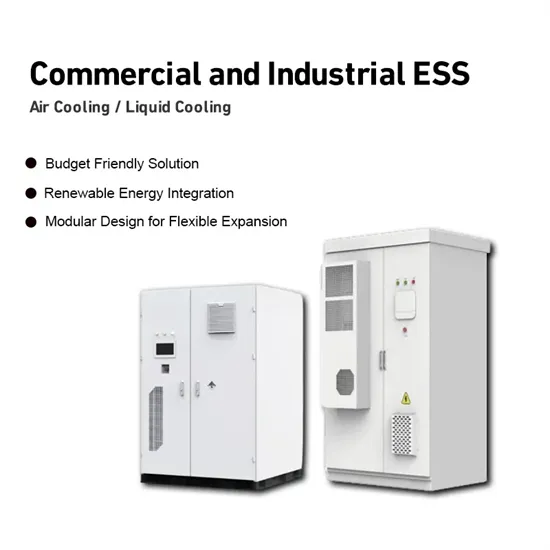

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.