Series Vs Parallel Ultimate Wiring Guide in 2024

For example, four 12V 10Ah batteries could be arranged as two series strings of 24V 10Ah, then wired in parallel to create a 24V 20Ah pack. This delivers

Get Price

Cells Per Battery Calculator

This formula allows you to determine the exact number of cells you need based on your specific voltage and capacity needs, simplifying the design of the battery pack.

Get Price

Battery Amp Hour Capacity Calculator

Use our battery capacity calculator to convert your battery capacity from watt hours to amp hours (Wh to Ah) or amp hours to watt hours (Ah to Wh).

Get Price

How to Balance Lithium Batteries with Parallel BMS?

Parallel Cells vs. Strings in Parallel When designing a lithium battery pack, engineers have two primary options: connecting individual cells

Get Price

The Ultimate Guide to 24V Lithium Ion Battery Packs

Whether you''re seeking efficiency, longevity, or eco-friendliness, these batteries pack a punch. Join us on a deep dive into the realm of 24V lithium ion battery packs, exploring their

Get Price

How many series strings of batteries can I have in parallel.

So to make up the 24V I am putting 2, 12V batteries in series but to increase the capacity I want to add more series strings in parallel. My idea is to have 4, 24V series strings

Get Price

How to Make a 24V Battery Pack

For lithium-ion battery packs, achieving 24V typically involves connecting seven 3.7V cells in series, reaching approximately 25.9V nominal and around 29.4V when fully charged.

Get Price

Connecting batteries in parallel – BatteryGuy Knowledge Base

There are two ways to wire batteries together, parallel and series. The illustration below show how these wiring variations can produce different voltage and amp hour outputs.

Get Price

Cells Per Battery Calculator

This formula allows you to determine the exact number of cells you need based on your specific voltage and capacity needs, simplifying the

Get Price

How Many Cells Are in a 24V LiFePO4 Battery? | Redway Tech

How Many Cells Are Required for a 24V Battery Pack? To create a 24V battery pack, you will need eight LiFePO4 cells connected in series. This arrangement is standard

Get Price

How many lithium cells in a 24v battery?

A 24V lithium battery usually contains six cells connected in series, each with a nominal voltage of about 3.7V. When fully charged, this setup provides around 25.2V, making

Get Price

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Get Price

How many strings are 48V20AH lithium battery packs? How to

The ternary lithium battery standard specifies a voltage of 3.7v, full of 4.2v, three strings are 12v, 48v requires four three strings, but the electric vehicle lead-acid battery is fully

Get Price

Battery pack calculator : Capacity, C-rating, ampere, charge and

How to size your storage battery pack : calculation of Capacity, C-rating (or C-rate), ampere, and runtime for battery bank or storage system (lithium, Alkaline, LiPo, Li-ION, Nimh or Lead

Get Price

48V lithium battery pack the difference between ternary lithium 13

Mar 24, 2021 48V lithium battery pack the difference between ternary lithium 13 string and 14 string For 48V battery packs, ternary lithium batteries generally use 13 strings or 14 strings,

Get Price

Building a 24 V battery bank: Using 12V batteries is much

Building your own battery packs is not hard, a lot of us do that here. We always recomend that you use Native Voltage Batteries, ie 12, 24 or 48 V. Placing Lithium Based

Get Price

How To Calculate Battery Size For LED Lights?

The charge controller or DC-DC regulator will keep the voltage constant (12V) which LED lights or strips are rated for. How Many LED Lights On a 12V Battery? How many LED

Get Price

How Many Cells In A 12V Lithium Battery? Guide To

A 12V lithium battery usually has four cells connected in series. Each cell has a nominal voltage of 3.2V. In comparison, lead acid batteries have a nominal voltage of 2V per

Get Price

Amp Hour Calculator (Battery Capacity Calculator) –

Learn how to estimate battery capacity using amp hours to match your home appliances. Enjoy reliable off-grid power with ease.

Get Price

How to Calculate the Number of Lithium Batteries in

Because different batteries have different voltage and capacity, they are assembled into lithium battery packs of specific specifications, and the number

Get Price

How to Calculate the Number of Lithium Batteries in Series and in

Because different batteries have different voltage and capacity, they are assembled into lithium battery packs of specific specifications, and the number of series and parallel required is

Get Price

Best Solar Lithium Battery for Off-Grid Systems in 2025

3 days ago· 2025 guide to choosing the best solar lithium battery for off-grid: LiFePO4, 48V, BMS protection, MPPT settings, sizing math, and compliance standards.

Get Price

How many strings are 48V20AH lithium battery

The ternary lithium battery standard specifies a voltage of 3.7v, full of 4.2v, three strings are 12v, 48v requires four three strings, but the electric

Get Price

How Many Cells in a Lithium Battery Pack? A Complete Guide to

For example, a lithium-ion battery has 3 cells for 11.1 volts, 4 cells for 14.8 volts, or 10 cells for 37 volts. Cells can be arranged in series to increase voltage or in parallel to boost

Get Price

Understanding 48V 20Ah Batteries: A Comprehensive Guide

How Many Cells Does It Take to Make a 48V 20Ah Battery? To construct a 48V 20Ah battery, a detailed understanding of battery cell configuration is essential. The most

Get Price

Understanding 400Ah Lithium Batteries: Your Energy

The 400Ah lithium battery stands out as a versatile and powerful option, offering long-lasting performance and high energy density. I plan to

Get Price

Lithium Battery Amp Hour Calculator

Our Lithium Battery Amp Hour Calculator is a comprehensive tool designed to help users determine battery capacity, runtime, and power

Get Price

6 FAQs about [How many strings of 24V lithium battery packs are needed]

How many lithium batteries can be connected in series?

Lithium battery pack 48V20AH generally single lithium battery is 3.5V, so 48V lithium battery pack needs 48/3.5=13.7, just take 14 in series. If the manufacturer has provided a set of 12V lithium batteries, then 4 can be connected in series. As long as the output voltage is 48V, the current is 2A or 4A.

How many batteries are in a 24v battery pack?

Lithium-ion batteries have a nominal voltage of 3.6-3.7 volts per cell, which means that a 24V battery pack will typically consist of 6-7 cells in series. The energy density of lithium-ion batteries is typically around 100-265 Wh/kg, which is much higher than other types of batteries.

How many strings should a lithium battery have?

Therefore, the lithium battery must also be about 58v, so it must be 14 strings to 58.8v, 14 times 4.2, and the iron-lithium full charge is about 3.4v, it must be four strings of 12v, 48v must be 16 strings, and so on, 60v There must be 20 strings in parallel with the same model and the same capacity.

How do I build a 24V lithium-ion battery pack?

To build a 24V lithium-ion battery pack, you will need to follow these steps: Choose the appropriate lithium-ion cells and number of cells required to achieve the desired voltage and capacity. Connect the cells in series to achieve the desired voltage. Connect the cells in parallel to achieve the desired capacity.

What are the different types of lithium battery packs?

Lithium battery series and parallel: There are both parallel and series combinations in the middle of the battery pack, which increases the voltage and increases the capacity. Such as 4000mAh, 6000mAh, 8000mAh, 5Ah, 10Ah, 20Ah, 30Ah, 50Ah, 100Ah and so on. Take 48V 20Ah lithium battery pack as an example Lithium Battery PACK

How many Li-ion cells should a 12V battery pack have?

Recognizing the difference is crucial for applications needing specific voltage outputs. For example, to create a 12V battery pack using standard Li-ion cells, you would need at least four cells in series (4 x 3.7V = 14.8V) to meet the voltage requirement.

More related information

-

How many strings of 48v lithium battery packs

How many strings of 48v lithium battery packs

-

How many 60v lithium battery packs are needed in Pakistan

How many 60v lithium battery packs are needed in Pakistan

-

How much is the lithium battery needed for 5G base stations worth

How much is the lithium battery needed for 5G base stations worth

-

How much does it cost to purchase lithium battery packs

How much does it cost to purchase lithium battery packs

-

How much does it cost to process lithium battery packs in Timor-Leste

How much does it cost to process lithium battery packs in Timor-Leste

-

How many strings are there for a 72v 60ah lithium battery pack in the Netherlands

How many strings are there for a 72v 60ah lithium battery pack in the Netherlands

-

How many lithium battery packs can be connected in parallel

How many lithium battery packs can be connected in parallel

-

How much is the price of lithium battery for energy storage in Albania

How much is the price of lithium battery for energy storage in Albania

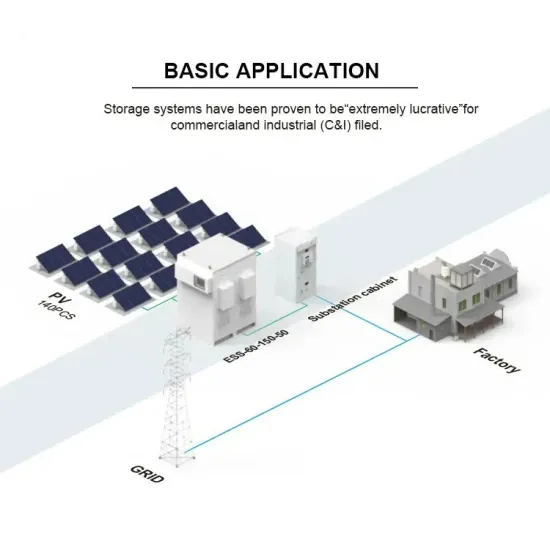

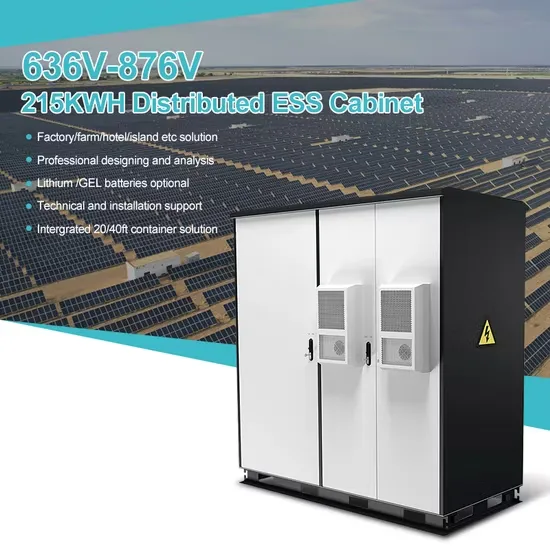

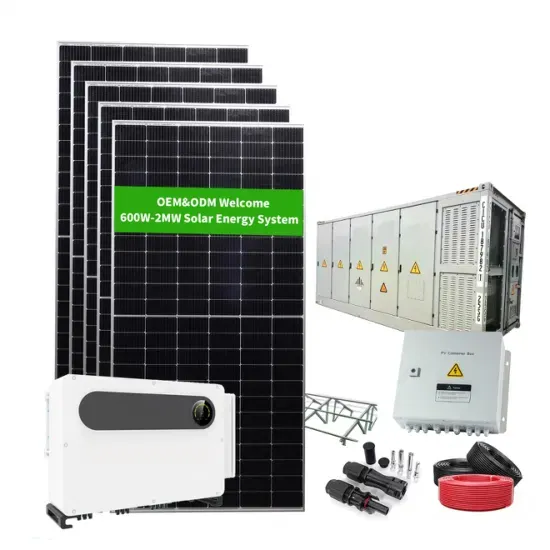

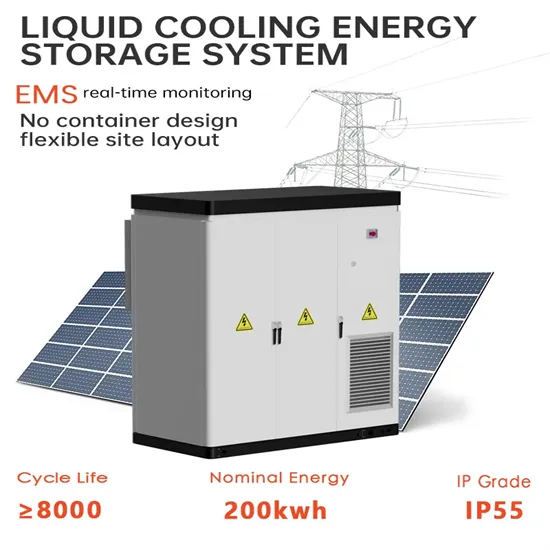

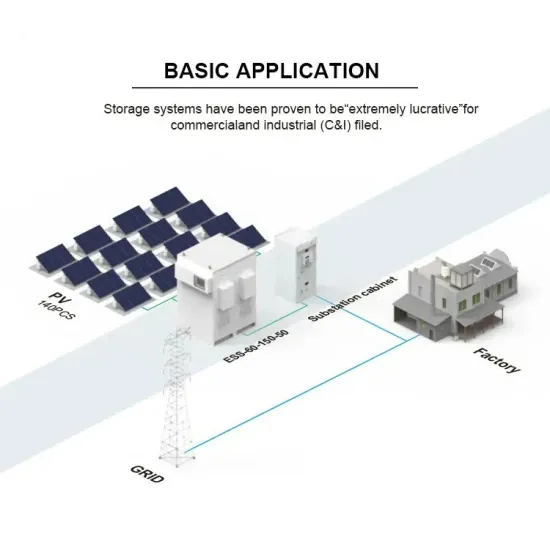

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.