Timor Leste Battery Pack Modules Market (2024-2030) | Value,

Historical Data and Forecast of Timor Leste Battery Pack Modules Market Revenues & Volume By Lithium Ceramic Battery for the Period 2020- 2030 Historical Data and Forecast of Timor

Get Price

How Much Does It Cost to Start Lithium-Ion Battery

Discover the essential costs involved in starting a lithium-ion battery manufacturing business. Take action now and ignite your entrepreneurial

Get Price

How Much Does a Lithium-Ion Battery Cost in 2025?

Lithium-ion batteries range from $10 to $20,000, depending on the device. For example, an EV battery costs more than a power tool battery.

Get Price

Timor Leste Lithium-ion Battery Recycling Market (2024-2030

Historical Data and Forecast of Timor Leste Lithium-ion Battery Recycling Market Revenues & Volume By Hydrometallurgical Process for the Period 2020-2030 Historical Data and Forecast

Get Price

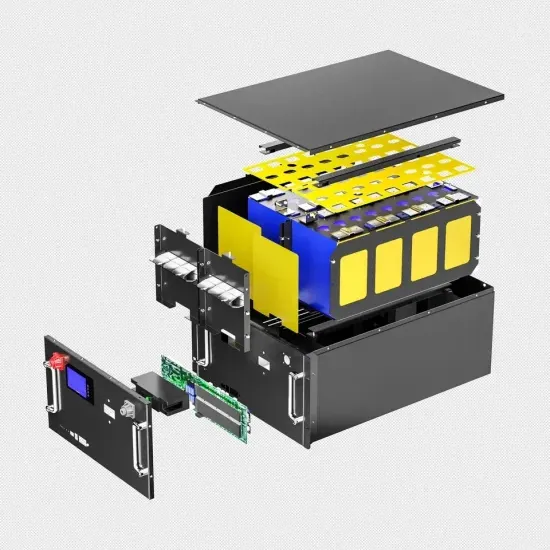

Lithium-ion Battery Pack Manufacturing Process & Design

At CMB, you do not need to pay any extra BMS development fees for 1-7S BMS. A 7-16S BMS, or Smart BMS, is equipped with CANBUS, UART 485, and RS232

Get Price

Lithium ion battery materials?

This data-file disaggregates the materials used in lithium ion batteries and their costs. The breakdown covers 25 categories (e.g., lithium, nickel, graphite), across 10 different battery

Get Price

What Are the 9 Operating Costs of Lithium Ion Battery

Discover the nine key operating costs in lithium-ion battery production. Get actionable insights to optimize expenses and boost efficiency.

Get Price

What Are the 2025 Startup Costs for Lithium Ion Battery

Discover the 9 essential startup costs for launching a lithium ion battery manufacturing business. Learn about equipment, materials, and operational expenses.

Get Price

Lithium Ion Battery Manufacturing: Cost Breakdown

Understanding your operating expenses is crucial when launching EnergyPact Lithium Solutions. Your costs include monthly overhead like

Get Price

Shipping Lithium Batteries from China: The Ultimate FAQ Guide

When it comes to shipping lithium batteries from China, there are many safety regulations you must follow. Comply with IATA regulations, label battery properly and use

Get Price

Lithium-Ion Battery Manufacturing Plant: Setup & Cost

Using the high ionic conductive electrolyte can reduce battery pack size while maintaining power output, contributing to higher battery energy density and

Get Price

Lithium-Ion Battery Costs: Manufacturing Prices, Components,

According to a 2021 report by BloombergNEF, the cost of lithium-ion batteries has dropped by 89% since 2010 due to increased production capabilities. Larger facilities can

Get Price

Timor-Leste Lithium Battery Pack OEM and Processing

This article explores OEM opportunities, local processing advantages, and how businesses can leverage renewable energy partnerships in Southeast Asia''s fastest-growing market.

Get Price

Lithium Manufacturing Plant Project Report 2025: Costs & ROI

Explore the Lithium Manufacturing Plant Project Report 2025 by Procurement Resource. Stay updated on Lithium manufacturing cost analysis, procurement insights, ROI, and market

Get Price

Lithium-ion Battery Pack Manufacturing Process

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Price

How Much Does a Custom Battery Pack Cost? A Complete

Estimating your custom battery pack cost. While it''s challenging to provide exact figures without specific project details, understanding these factors can help in budgeting. For a tailored

Get Price

Timor Leste Solid State Lithium Battery Market (2025-2031

Historical Data and Forecast of Timor Leste Solid State Lithium Battery Market Revenues & Volume By Polymer based for the Period 2021-2031 Historical Data and Forecast of Timor

Get Price

Lithium-Ion Battery Manufacturing Plant: Setup & Cost

Using the high ionic conductive electrolyte can reduce battery pack size while maintaining power output, contributing to higher battery energy density and lower overall pack cost. Furthermore,

Get Price

How Much Does a Lithium Battery Recycling Plant Cost?

When planning a lithium battery recycling plant, it''s crucial to explore funding options, grants, and subsidies available for green initiatives. Additionally, the market demand

Get Price

Optimal Lithium Battery Charging: A Definitive Guide

Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Get Price

How Much Does it Cost to Replace an EV Battery? | U.S. News

According to the DOE, the cost of a lithium-ion EV battery was 89 percent lower in 2022 than it was in 2008, and this trend is continuing as production volume increases and

Get Price

Optimize Your Lithium-ion Battery Production Costs | Tset

In the following section, we will examine the cell assembly process and finalization of the battery cell: Our detailed cost breakdown of the lithium-ion battery cells production

Get Price

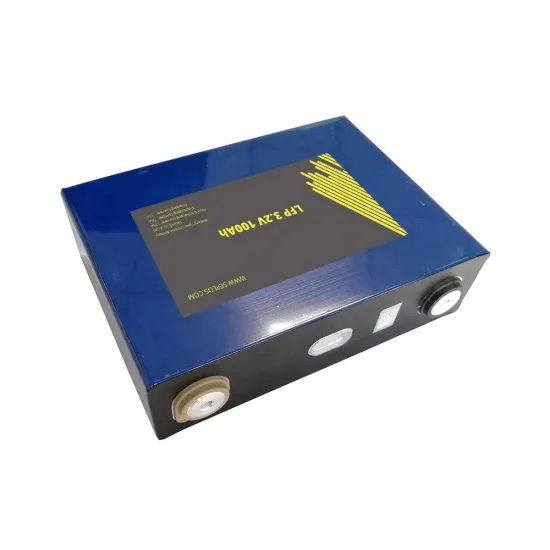

Top Lithium-Ion Battery Suppliers in Timor-Leste

Wholesale Lithium-Ion Battery for PV Systems? Simply put, a lithium-ion battery (commonly referred to as a Li-ion battery or LIB) is a type of rechargeable battery that is commonly used

Get Price

Lithium Ion Battery Manufacturing: Cost Breakdown

How Much Does it Cost to Operate a Lithium Ion Battery Manufacturing Business? Understanding your operating expenses is crucial

Get Price

Lithium Ion Battery Manufacturing: Cost Breakdown

Understanding your operating expenses is crucial when launching EnergyPact Lithium Solutions. Your costs include monthly overhead like facility rent, employee salaries,

Get Price

Lithium-ion Battery Pack Manufacturing Process

At CMB, you do not need to pay any extra BMS development fees for 1-7S BMS. A 7-16S BMS, or Smart BMS, is equipped with CANBUS,

Get Price

6 FAQs about [How much does it cost to process lithium battery packs in Timor-Leste ]

How much does a lithium ion battery cost?

Lithium ion battery costs range from $40-140/kWh, depending on the chemistry (LFP vs NMC), geography (China vs the West) and cost basis (cash cost, marginal cost and actual pricing). This data-file is a breakdown of lithium ion battery costs, across c15 materials and c20 manufacturing stages, so input assumptions can be stress-tested.

What is the lithium-ion battery manufacturing plant project report 2025?

IMARC Group’s report, titled “ Lithium-Ion Battery Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue, ” provides a complete roadmap for setting up a lithium-ion battery manufacturing plant.

What is a lithium-ion battery manufacturing plant?

A lithium-ion battery manufacturing plant is a facility designed for the large-scale production of rechargeable battery cells used in various modern technologies. These plants carry out a series of precision-driven processes, including electrode preparation, cell assembly, electrolyte filling, formation, and quality testing.

How are materials costs of lithium ion batteries calculated?

The breakdown covers 25 categories (e.g., lithium, nickel, graphite), across 10 different battery chemistries (e.g., NCA, NMC, LFP and others, chart below). Materials costs of lithium ion batteries can be calculated by comparing our mass balances above with the costs of different input commodity prices.

When will lithium-ion battery production start in India?

In January 2025, the International Battery Company (IBC) announced that it will start lithium-ion battery production at its Giga Factory Unit in Bengaluru within nine months. The INR 390 Crore project, developed in collaboration with Mahanagar Gas Ltd., is India’s first lithium-ion battery manufacturing facility and will create 300 direct jobs.

What is capital investment in a lithium-ion battery manufacturing plant?

Capital Investment (CapEx): For a lithium-ion battery manufacturing plant, machinery represents the most significant portion of total capital investment, accounting for majority of the total CapEx. This includes specialized equipment for electrode processing, cell assembly, electrolyte injection, and testing systems.

More related information

-

How much does it cost to purchase lithium battery packs

How much does it cost to purchase lithium battery packs

-

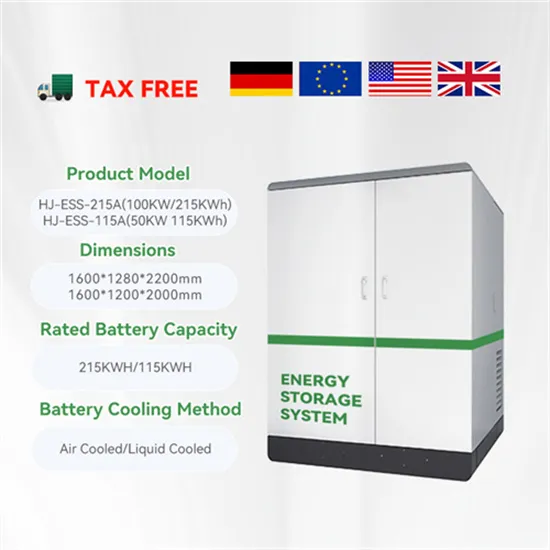

How much does a lithium battery energy storage cabinet cost in New Zealand

How much does a lithium battery energy storage cabinet cost in New Zealand

-

How much does a 60V Chinese lithium battery pack cost

How much does a 60V Chinese lithium battery pack cost

-

How much does a lithium battery energy storage power station cost in Kyrgyzstan

How much does a lithium battery energy storage power station cost in Kyrgyzstan

-

How much does it cost to replace the lithium battery station cabinet in Sierra Leone

How much does it cost to replace the lithium battery station cabinet in Sierra Leone

-

How many strings of 24V lithium battery packs are needed

How many strings of 24V lithium battery packs are needed

-

How many lithium battery packs can be connected in parallel

How many lithium battery packs can be connected in parallel

-

How much does German energy storage lithium battery cost

How much does German energy storage lithium battery cost

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.