Silicon Solar Cells

Amorphous silicon solar panels are thin layers of amorphous silicon placed on a substrate. These are gaining popularity because of their mass manufacturing capabilities and their potential to

Get Price

What is the silicon used in solar power generation?

Silicon used in solar power generation manifests in various forms, primarily classified into monocrystalline, polycrystalline, and amorphous

Get Price

How Are Solar Panels Made? A Comprehensive

Curious about how solar panels are made? Learn the basics of photovoltaic technology and what goes into making and testing solar panels.

Get Price

Monocrystalline photovoltaic panels: what they are and their

Monocrystalline photovoltaic panels are advanced devices designed to convert sunlight into electrical energy through a process called the photovoltaic effect. Their

Get Price

why is silicon used in photovoltaic cells › ›

When it comes to solar energy, photovoltaic cells are the key component that converts sunlight into electricity. These cells rely on silicon, a widely used

Get Price

Which element is used in a solar cell? What is silicon?

Silicon is a semiconductor material whose properties fit perfectly in solar cells to produce electrical energy. Pure silicon is a grayish crystalline

Get Price

What Are Solar Panels Made Of and How Are They Made?

Most panels on the market are made of monocrystalline, polycrystalline, or thin film ("amorphous") silicon. In this article, we''ll explain how solar cells are made and what parts are

Get Price

What Are Solar Panels Made Of and How Are They

Most panels on the market are made of monocrystalline, polycrystalline, or thin film ("amorphous") silicon. In this article, we''ll explain

Get Price

Why Silicon is the Most Widely Used Material in Solar

Monocrystalline silicon panels are top performers in efficiency and longevity, leading to significant cost savings over time. With evolving

Get Price

Why can silicon be used to make solar cells? | NenPower

1. Silicon possesses unique semiconductor properties, making it essential for solar cell production, 2. Silicon is abundant and cost-effective,

Get Price

What Materials Are Used in Solar Panels? A Detailed Look

Discover the essential materials that make up a solar panel, from silicon cells to aluminum frames, and how they harness the sun''s power.

Get Price

What kind of silicon is used in solar photovoltaic panels?

Monocrystalline silicon is widely recognized as the gold standard in the solar photovoltaic panel industry. This type of silicon is produced from a single, continuous crystal

Get Price

Different Types of Silicon Used in Solar Panel Production

Explore the diverse types of silicon crucial for solar panel production and learn how they influence efficiency and cost-effectiveness in

Get Price

What is the silicon used in solar power generation? | NenPower

Silicon used in solar power generation manifests in various forms, primarily classified into monocrystalline, polycrystalline, and amorphous silicon. Each type possesses

Get Price

What Chemicals Are Used to Make Solar Panels?

The market for solar photovoltaic (PV) is growing fast. It''s expected to be more than INR 1.5 trillion by 2027. India''s move towards more renewable

Get Price

Why Silicon is the Most Widely Used Material in Solar Panels

Monocrystalline silicon panels are top performers in efficiency and longevity, leading to significant cost savings over time. With evolving technologies like PERC and HIT

Get Price

Silicon Solar Cells: Harnessing the Power of

Key Takeaways Silicon solar cells are crucial components of photovoltaic technology, converting sunlight into electrical energy. There are two main

Get Price

Solar Photovoltaic Cell Basics

Amorphous silicon solar panels are thin layers of amorphous silicon placed on a substrate. These are gaining popularity because of their mass manufacturing

Get Price

Which element is used in a solar cell? What is silicon?

Silicon is a semiconductor material whose properties fit perfectly in solar cells to produce electrical energy. Pure silicon is a grayish crystalline elemental mineral with a metallic

Get Price

What type of silicon is used in solar cells?

Silicon is a naturally occurring element, and it is the second most abundant element in the earth''s crust after oxygen. Its unique electrical properties make it ideal for use in solar cells. There are

Get Price

What Are Solar Panels Made Of? Detailed Materials

Key Insights The main materials used in solar panels, including silicon solar cells, tempered glass, and metal frames. How monocrystalline

Get Price

How Are Solar Panels Made?

There''s a lot that goes into making solar happen beyond building panels, but responsibly accelerating solar panel manufacturing and installation is a critical step in the

Get Price

Solar Photovoltaic Cell Basics

Silicon is, by far, the most common semiconductor material used in solar cells, representing approximately 95% of the modules sold today. It is also the second most abundant material on

Get Price

Comprehensive Guide to Solar Panel Types

This guide will illustrate the different types of solar panels available on the market today, their strengths and weaknesses, and which is best suited for specific

Get Price

Silicon Solar Cell: Types, Uses, Advantages

The majority of solar energy systems used today power homes, businesses, and industries by converting sunlight into electrical power. These systems are

Get Price

why is silicon used in photovoltaic cells › › Basengreen Energy

When it comes to solar energy, photovoltaic cells are the key component that converts sunlight into electricity. These cells rely on silicon, a widely used semiconductor, to achieve this

Get Price

News

A solar panel sealant is an adhesive material designed to form a strong barrier between a photovoltaic (PV) module and its frame or mounting system. These

Get Price

Silicon for Solar Cells: Everything You Need to Know

When two types of semiconductors (p-type and n-type) are joined to form a p-n junction, the resultant material exhibits photovoltaic properties. Among the

Get Price

Silicon for Solar Cells: Everything You Need to Know

When two types of semiconductors (p-type and n-type) are joined to form a p-n junction, the resultant material exhibits photovoltaic properties. Among the discovered semiconductors,

Get Price

How Are Solar Panels Made?

As solar energy use becomes more prevalent, so does information about how it''s harnessed and used. Photovoltaic, or solar, panels can often be found in both

Get Price

Photovoltaic panels: operation and electrical production

Photovoltaic materials used in solar panels are generally of two types: crystalline silicon and amorphous silicon. Crystalline silicon is the most common and efficient, while

Get Price

6 FAQs about [What kind of silicon is used to make solar photovoltaic panels]

Which material is used for solar cell manufacturing?

These semiconductors are the most used material for solar cell manufacturing. Silicon cells are the basis of solar power. It is the primary element of solar panels and converting solar energy into electricity. Photovoltaic panels can be built with amorphous or crystalline silicon. Solar cell efficiencies depend on the silicon configuration.

Can silicon be used in photovoltaic cells?

Silicon can be sourced from silica, found in sand, quartz, and other materials. The process of extracting and purifying silicon is well-established, adding to its appeal for use in photovoltaic cells. 2. Optimal semiconductor properties The bandgap energy of silicon is ideal for solar energy conversion.

Is silicon a good material for solar panels?

Silicon is abundant in nature, making it a cost-effective and readily available material for photovoltaic cells. With its abundance, the production and scalability of silicon-based solar panels are facilitated, driving down the cost of solar energy. Silicon can be sourced from silica, found in sand, quartz, and other materials.

What is a silicon solar cell?

Pure crystalline silicon, which has been used as an electrical component for decades, is the basic component of a conventional solar cell. Because silicon solar technology gained traction in the 1950s, silicon solar panels are called “first-generation” panels. Silicon now accounts for more than 90% of the solar cell industry.

Why is silicon used in solar cells?

Silicon now accounts for more than 90% of the solar cell industry. Silicon is a cost-effective material with high energy efficiency. That is why it is frequently employed as a semiconductor material in first solar cells. Aside from that, it possesses strong photoconductivity, corrosion resistance, and long-term durability.

Why are solar panels made of silicon?

Silicon’s dominance in solar technology is rooted in its ideal semiconductor properties and durability. Solar cells made of silicon offer an impressive lifespan, exceeding two decades of service with minimal efficiency loss. Monocrystalline silicon panels are top performers in efficiency and longevity, leading to significant cost savings over time.

More related information

-

Photovoltaic silicon solar panels

Photovoltaic silicon solar panels

-

Can photovoltaic panels be used as solar panels

Can photovoltaic panels be used as solar panels

-

What solar panels do photovoltaic manufacturers use

What solar panels do photovoltaic manufacturers use

-

North African companies that make solar photovoltaic panels

North African companies that make solar photovoltaic panels

-

What kind of battery should be used for home solar integrated machine

What kind of battery should be used for home solar integrated machine

-

What kind of battery is mainly used for wind and solar energy storage

What kind of battery is mainly used for wind and solar energy storage

-

How many photovoltaic panels are used in a 48v solar system

How many photovoltaic panels are used in a 48v solar system

-

What is the appropriate cost of solar panels for photovoltaic projects

What is the appropriate cost of solar panels for photovoltaic projects

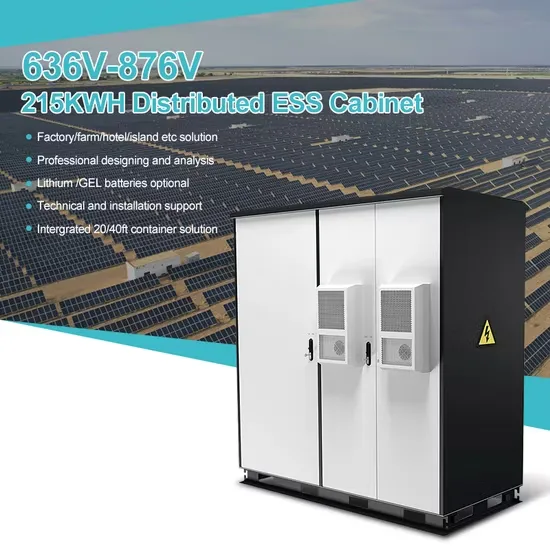

Commercial & Industrial Solar Storage Market Growth

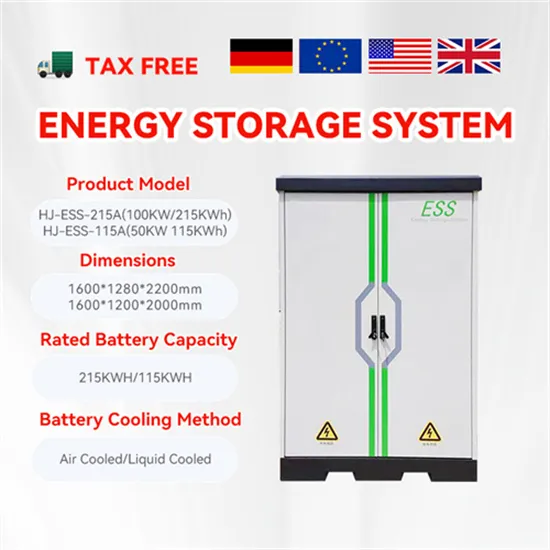

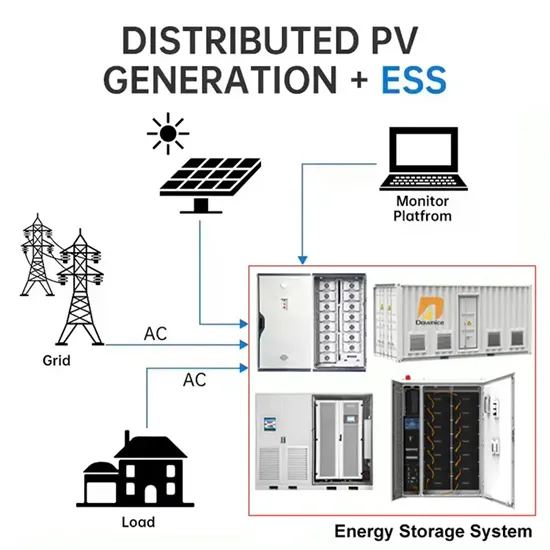

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

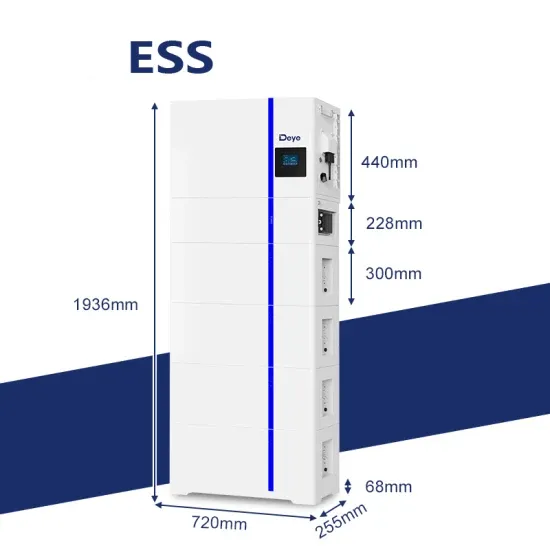

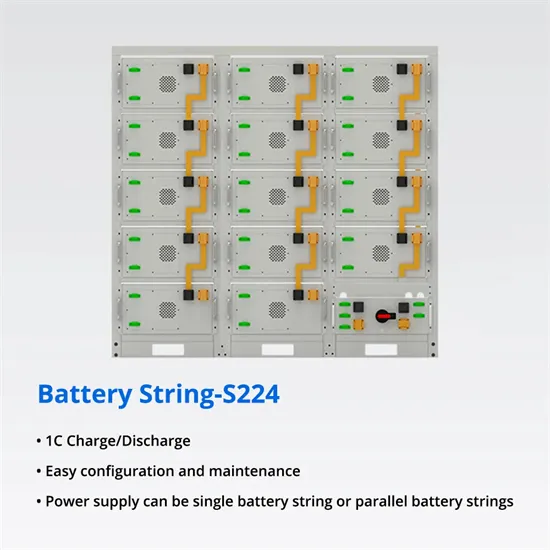

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.