Solar Photovoltaic Cells: Types and Applications

Discover various solar photovoltaic cells – monocrystalline silicon for high efficiency, polycrystalline silicon for affordability, multi-junction cells for

Get Price

What is Monocrystalline Solar Panel? Advantages and

The main difference between monocrystalline and polycrystalline solar cells in Hindi is the type of silicon solar cell they use; monocrystalline

Get Price

Polycrystalline Silicon

Polycrystalline silicon is essential to the solar power industry, offering a cost-effective and durable material for solar cell production. Its balance of affordability and

Get Price

Properties of polycrystalline silicon cell

Polycrystalline Photovoltaic Panels Polycrystalline solar cells have an efficiency range of 12% to 21%. They are often produced by recycling discarded electronic

Get Price

Polycrystalline Solar Panel: Features, Working

As there are multiple silicon crystals in each cell, polycrystalline panels allow little movement of electrons inside the cells. These solar panels

Get Price

Fabrication and Characterization of Polycrystalline Silicon

Generally the thesis is separated into three parts, introductory theory, solar cell fabrication, and finally characterization of fabricated solar cells utilizing their I-V characteristics obtained.

Get Price

Polycrystalline silicon

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity, polycrystalline form of silicon, used as a raw material by the solar photovoltaic and

Get Price

Photovoltaic Cell

Photovoltaic Cell Structure A photovoltaic (PV) cell, commonly known as a solar cell, is a device that directly converts light energy into

Get Price

What are polycrystalline solar panels?

This is lower than monocrystalline panels but higher than some other types. Temperature resilience: Solar panel performance degrades under high heat conditions for all

Get Price

(PDF) Performance study of Monocrystalline and

Photovoltaic solar technology has emerged as a sustainable and environmental friendly source of energy, capable of mitigate climate change

Get Price

Types of photovoltaic cells

Several of these solar cells are required to construct a solar panel and many panels make up a photovoltaic array. There are three types of PV cell

Get Price

Polycrystalline Silicon Cells: production and

Polycrystalline silicon is a multicrystalline form of silicon with high purity and used to make solar photovoltaic cells.

Get Price

What Is a Monocrystalline Solar Panel? Definition,

For a standard 6kW system, monocrystalline panels would have a final cost between $6,000 and $9,000, whereas polycrystalline systems are

Get Price

Polycrystalline silicon solar cells

To increase the efficiency and usage of the least material, thin-film technologies are the most favorable. These are more reliable and are also cost-effective. The major cell

Get Price

What are polycrystalline silicon solar materials? | NenPower

The photovoltaic characteristics of polycrystalline silicon make it essential in advancing solar energy adoption. While it does not match the efficiency rates of

Get Price

(PDF) Comparative Analysis of Solar Cell Efficiency between

This study applies a direct measurement method using a monocrystalline type solar panel and a polycrystalline type with the same power capacity with a peak capacity of 50 Wp.

Get Price

Polycrystalline silicon

OverviewVs monocrystalline siliconComponentsDeposition methodsUpgraded metallurgical-grade siliconPotential applicationsNovel ideasManufacturers

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity, polycrystalline form of silicon, used as a raw material by the solar photovoltaic and electronics industry. Polysilicon is produced from metallurgical grade silicon by a chemical purification process, called the Siemens process. This process involves distillation of volatil

Get Price

The Difference Between Polycrystalline Silicon And

Polycrystalline structure: Polycrystalline silicon is composed of multiple grains, with atoms arranged in an orderly manner within each grain,

Get Price

The Difference Between Polycrystalline Silicon And

Polycrystalline structure: Polycrystalline silicon is composed of multiple grains, with atoms arranged in an orderly manner within each grain, but atoms arranged randomly at the

Get Price

How to Distinguish Mono, Poly and Amorphous Silicon Solar Panels?

Distinguishing between monocrystalline silicon, polycrystalline silicon, and amorphous silicon solar panels can be done by examining their physical appearance and

Get Price

What are polycrystalline silicon solar materials?

The photovoltaic characteristics of polycrystalline silicon make it essential in advancing solar energy adoption. While it does not match the

Get Price

What kind of silicon is used in solar photovoltaic panels?

1. SILICON TYPES IN SOLAR PHOTOVOLTAIC PANELS Silicon is primarily categorized into three types utilized in solar photovoltaic panels: monocrystalline silicon,

Get Price

Crystalline and Polycrystalline Silicon PV Technology

Crystalline and Polycrystalline Silicon PV Technology Crystalline silicon PV cells are used in the largest quantity of all types of panels on the market, representing about 90% of

Get Price

What are polycrystalline solar panels?

The photovoltaic (PV) cell layer in solar panels uses a silicon crystal to capture sunlight and convert it to electricity. In polycrystalline panels, the sheet is made by melting

Get Price

Polycrystalline Solar Panel: Definition, How it Works,

Polycrystalline, multicrystalline, or poly solar panels are a type of photovoltaic (PV) panel used to generate electricity from sunlight. They are

Get Price

Polycrystalline Silicon Cells: production and characteristics

Polycrystalline silicon is a multicrystalline form of silicon with high purity and used to make solar photovoltaic cells.

Get Price

High-efficiency polycrystalline solar cells via COC-SiO2 anti

The photovoltaic cells are classified into three generations based on the materials employed and the period of their development. The monocrystalline and polycrystalline silicon

Get Price

Polycrystalline Solar Panel: Features, Working Principle

As there are multiple silicon crystals in each cell, polycrystalline panels allow little movement of electrons inside the cells. These solar panels absorb energy from the sun and

Get Price

Properties of polycrystalline silicon cell

The photovoltaic (PV) cell layer in solar panels uses a silicon crystal to capture sunlight and convert it to electricity. In polycrystalline panels, the sheet is made by melting

Get Price

Types of solar panels: monocrystalline, polycrystalline,

There are three main types of solar panels used in solar projects: monocrystalline, polycrystalline, and thin-film. Each kind of solar panel has different

Get Price

More related information

-

Annual power generation rate of polycrystalline silicon photovoltaic panels

Annual power generation rate of polycrystalline silicon photovoltaic panels

-

Polycrystalline silicon photovoltaic panels for power generation

Polycrystalline silicon photovoltaic panels for power generation

-

Photovoltaic panels polycrystalline silicon panels

Photovoltaic panels polycrystalline silicon panels

-

Are monocrystalline silicon photovoltaic panels afraid of corrosion

Are monocrystalline silicon photovoltaic panels afraid of corrosion

-

Polycrystalline silicon double-glass photovoltaic modules

Polycrystalline silicon double-glass photovoltaic modules

-

What is the voltage of ten photovoltaic panels

What is the voltage of ten photovoltaic panels

-

Haiti polycrystalline solar photovoltaic panels

Haiti polycrystalline solar photovoltaic panels

-

Czech monocrystalline silicon photovoltaic panels

Czech monocrystalline silicon photovoltaic panels

Commercial & Industrial Solar Storage Market Growth

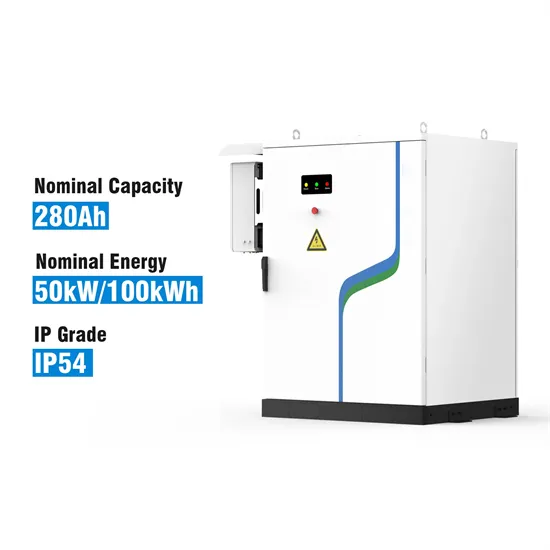

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

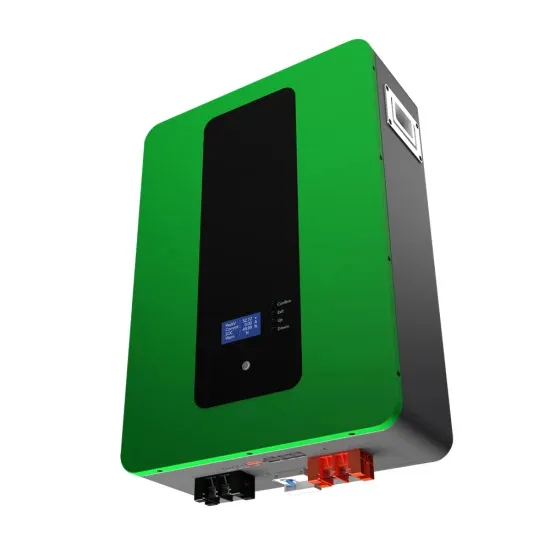

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.