An experimental study on the influence of environmental

The impact of environmental temperature on the battery pack must be investigated to obtain the optimum performance. Thermal insulation is an effective way to

Get Price

Sustainable manufacturing practices for EV battery packs:

Present-day approaches to creating EV battery packs are performed often with the help of restricted and hazardous materials and energy-demanding methods, having a rather

Get Price

Assessing the Lifecycle Environmental Impact of Traction Battery Packs

This article examines the lifecycle environmental impact of traction battery packs, from raw material extraction to manufacturing, usage, and recycling, and highlights the role of

Get Price

Automotive Battery Pack Standards and Design Characteristics:

Fig. 1 shows the ideal battery pack and major constraints. The battery pack, as the main energy storage device for EVs, delivers the required energy and power with a reliable

Get Price

Life cycle environmental impact assessment for battery-powered

As an important part of electric vehicles, lithium-ion battery packs will have a certain environmental impact in the use stage. To analyze the comprehensive environmental impact,

Get Price

Life cycle environmental impact assessment for

As an important part of electric vehicles, lithium-ion battery packs will have a certain environmental impact in the use stage. To analyze the comprehensive

Get Price

The Environmental Impact of Battery Storage

From reducing greenhouse gas emissions to grappling with the environmental costs of production, and even tackling safety concerns and recycling, there''s a lot to unpack.

Get Price

Apple''s new MagSafe Battery doesn''t just work with iPhone Air

2 days ago· The first battery pack charged with Lightning, and Apple let third-party accessory makers have the market for MagSafe battery packs with USB-C.

Get Price

Thermal management requirements in battery packs: An analysis

A degradation-aware electro-thermal framework for battery packs with a pack-level electrical model and a thermal resistance network of a heat pipe-fan (HP-F)–based battery thermal

Get Price

What Are Battery Cells, Battery Modules, And Battery

Here we''ll talk about the differences between battery cells, modules, and packs, and learn how to tell these key components for effective

Get Price

Pack Testing

Battery packs are designed to last a decade or more in harsh environments, preferably without the need to be serviced or repaired. Therefore it is important to carry out comprehensive pack

Get Price

Environmental Chambers for Battery Testing: How They Ensure

This article explores why batteries fail, how environmental chambers for battery testing mitigate these risks, and how you can use them to enhance product safety and compliance.

Get Price

Everything You Need to Know About EV Battery and

EV batteries and battery packs are complex systems, requiring a comprehensive design and testing strategy to help ensure safe and efficient

Get Price

Understanding Battery Storage Environmental Assessments: An

Explore the critical role of battery storage environmental assessments in sustainable energy systems. Battery storage systems are emerging as critical elements in the

Get Price

Designing Battery Packs for Harsh Environment Mission-Critical

Learn design considerations and techniques for designing and manufacturing battery packs for harsh environments.

Get Price

Battery Packs Explained: How They Work, Usage, and a

What Are Battery Packs and How Do They Work? Battery packs are portable power sources that store electrical energy for later use. They typically consist of multiple

Get Price

The Environmental Impact of Battery Storage

From reducing greenhouse gas emissions to grappling with the environmental costs of production, and even tackling safety concerns and

Get Price

Direct recycling of Li-ion batteries from cell to pack level

Direct recycling methods can repair and regenerate battery constituents without destroying the materials down to the ionic or molecular level, unlike conventional hydro/pyrometallurgy. This

Get Price

Battery Thermal Management System

Creating battery thermal software models that simulate the heat transfer process can help engineers analyze tradeoffs in design parameters, evaluate

Get Price

A Comprehensive Review of Thermal Management Methods and

The scientific aim of the study is to propose a comprehensive review of thermal management systems (TMSs) used in electric vehicle (EV) battery packs on matters pertaining

Get Price

A Comprehensive Approach to Battery Module and Pack Testing

Testing helps evaluate the ability of battery modules and packs to operate under various conditions, such as high loads, extreme temperatures, and prolonged cycling. Testing for

Get Price

Battery Packs

Battery pack is work by combining several battery cells in series or parallel configurations to provide the required voltage and current output. The

Get Price

Assessing the Lifecycle Environmental Impact of

This article examines the lifecycle environmental impact of traction battery packs, from raw material extraction to manufacturing, usage, and

Get Price

Battery Packaging Architectures: Materials

Challenges surrounding battery packaging architecture include dealing with packaging space, thermal management, and optimizing battery

Get Price

Environmental Testing of Batteries

This versatility helps us to act as the best partner possible for your environmental battery testing needs. TÜV SÜD offers a wide array of different environmental battery testing services to

Get Price

Understanding Battery Storage Environmental

Explore the critical role of battery storage environmental assessments in sustainable energy systems. Battery storage systems are

Get Price

Environmental Chambers for Battery Testing: How

This article explores why batteries fail, how environmental chambers for battery testing mitigate these risks, and how you can use them to enhance product

Get Price

The Fundamentals of Battery/Module Pack Test

The Importance of Battery Module and Pack Testing The battery market is growing rapidly due to the acceleration of electrification in the automotive, aerospace and energy industries. In turn,

Get Price

Battery Pack Monitor System for Environmental Testing

DMC developed a cost-effective, fully automated, and portable testing system designed specifically for monitoring large battery packs through environmental, cycling, and endurance

Get Price

Designing Battery Packs for Harsh Environment

Learn design considerations and techniques for designing and manufacturing battery packs for harsh environments.

Get Price

6 FAQs about [Pack battery environmental control]

What is the environmental impact of battery pack?

In addition, the electrical structure of the operating area is an important factor for the potential environmental impact of the battery pack. In terms of power structure, coal power in China currently has significant carbon footprint, ecological footprint, acidification potential and eutrophication potential.

Which battery pack has the most environmental impact?

Li–S battery pack was the cleanest, while LMO/NMC-C had the largest environmental load. The more electric energy consumed by the battery pack in the EVs, the greater the environmental impact caused by the existence of nonclean energy structure in the electric power composition, so the lower the environmental characteristics.

How EV batteries impact the environment?

Table 3 gives the net impact of EV batteries based on electricity from average global grid is presented in Table 3 below. Battery production is responsible for 20 % and battery recycling offsets the 5 %, while BEV usage causes the remaining 80 % for the battery’s environmental footprint in its lifecycle. Table 3.

How can we reduce the environmental impact of battery storage?

Honestly, improving recycling and reuse practices is one of the most important steps we can take to reduce the environmental impact of battery storage. The U.S. battery storage market is booming, and it’s exciting to watch. Plans are in place to almost double the storage capacity by the end of 2024.

What information is required for EV battery pack layout?

Multidisciplinary information in materials, electrochemistry, electrics and electronics, thermal engineering, and mechanical engineering is required for the overall layout of the EV battery pack. The intricacy of the EV battery packs layout will growth if the environmental element is included.

Are EV batteries sustainable?

Existing strategies inside the EV battery industries in the main focus on enhancing battery performance and value-effectiveness . However, they frequently overlook critical components of sustainability, together with the environmental effect of cloth extraction, electricity use in manufacturing, and quit-of-life management.

More related information

-

Pack lithium battery environmental requirements

Pack lithium battery environmental requirements

-

Pack lithium battery quality control points

Pack lithium battery quality control points

-

Turkmenistan large-cell lithium battery pack

Turkmenistan large-cell lithium battery pack

-

Portugal pack battery

Portugal pack battery

-

24v 50kWh lithium iron phosphate battery pack

24v 50kWh lithium iron phosphate battery pack

-

Lithium battery pack recommendation

Lithium battery pack recommendation

-

How much does a base station battery pack cost

How much does a base station battery pack cost

-

Lithium-ion pack battery standards

Lithium-ion pack battery standards

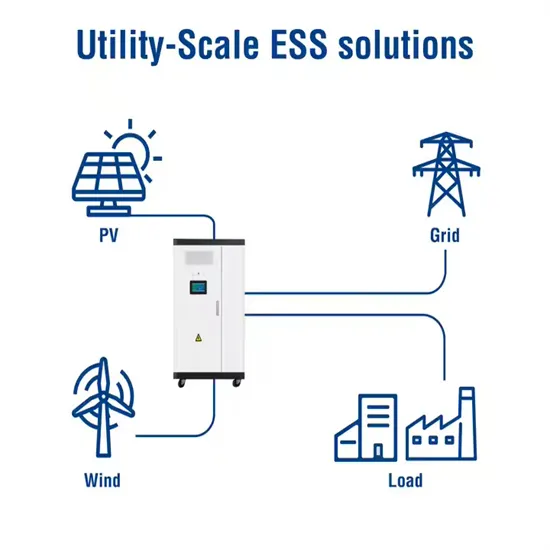

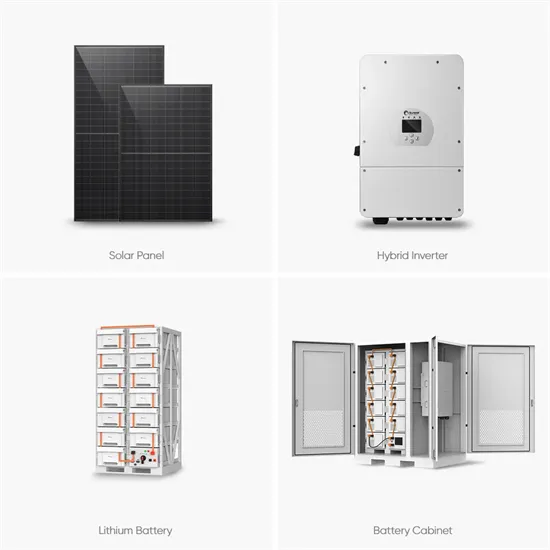

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

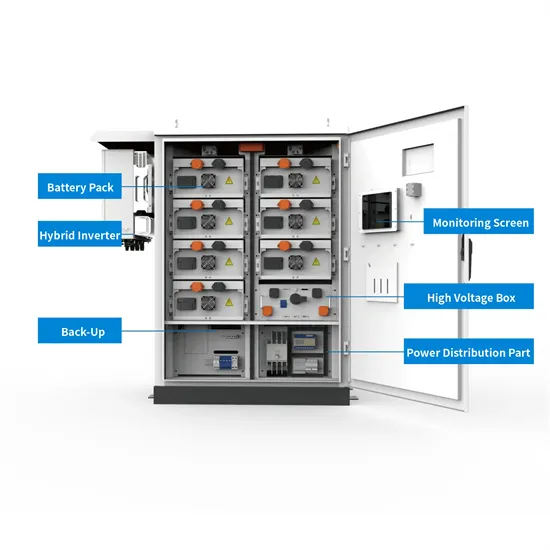

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.