Performance Analysis of Optimized Active Cell Balancing Circuits

The study provides valuable insights into the design and implementation of high-performance active balancing circuits, paving the way for more reliable and efficient LIB packs.

Get Price

Battery Cell Balancing: What to Balance and How

Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device.

Get Price

Sep

lithium battery pack solutions for medical applications Designing and manufacturing lithium battery pack solutions for medical applications, identify the appropriate lithium chemistry, combined

Get Price

Adaptive Recombination-Based Control Strategy for Cell Balancing

To address this need, researchers have developed numerous active balancing strategies, often using converter-based, modular, or algorithm-driven techniques. Table 2

Get Price

Factors Influencing the Design of Custom Lithium-Ion

As experts in custom battery pack design, we understand the intricate details that go into creating high-performance and reliable power

Get Price

BMS Board Balance Management: How to Balance

Battery Balancing, Why Is It Important? In various electronic devices and new energy applications, batteries are indispensable energy

Get Price

Battery balancing: optimizing performance and

As a result, battery balancing technology has emerged, aiming to achieve relative consistency in voltage, capacity, and state among the

Get Price

Passive Balancing

Passive balancing is perhaps the simplest form of cell balancing with a resistor that is switched on and off across the cell. In the example shown with the 3 cells the balancing resistor would be

Get Price

A Deeper Look into Active Balancing on BMS

Simplicity and efficiency—even if not the shared pursuit of all designers—are the goals for most. Following the principle that simplicity wins, this

Get Price

Active balancing: How it works and what are its advantages

As an alternative to passive balancing, active balancing uses power conversion to redistribute charge among the cells in a battery pack. This enables a higher balancing current,

Get Price

A Guide to Designing A BMS Circuit Diagram for Li

The Voltage Balancing Circuit is a key element in Li-ion battery management, addressing the need to balance individual cell voltages to

Get Price

Adaptive Recombination-Based Control Strategy for

To address this need, researchers have developed numerous active balancing strategies, often using converter-based, modular, or

Get Price

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

Match the cells to combine in parallel/series with the rePackr - 18650 pack builder tool. This is done according to capacity and internal resistance to get the most similar values in each pack

Get Price

Active Cell Balancing in Battery Packs

For this application, the battery pack consists of 12 NiMH cells with a nominal capacity of 1700 mAh. The maximum load current of the application is 500 mA. The balancing is active during

Get Price

16-Cell Lithium-Ion Battery Active Balance Reference Design

The 16-Cell Lithium-Ion Battery Active Balance Reference Design describes a complete solution for high current balancing in battery stacks used for high voltage applications like xEV vehicles

Get Price

Microsoft Word

Abstract - This paper presents the implementation of an active balancing technique for the management of four Lithium Iron Phosphate (LiFePO4) cells of high capacity, connected in

Get Price

What is Cell Balancing for Lithium-ion Battery Packs?

Learn about cell balancing for lithium-ion battery packs, its importance, methods, and benefits in ensuring optimal battery performance

Get Price

A critical review of battery cell balancing techniques, optimal

This optimization includes a comprehensive strategy that consist of battery cell balancing approaches, optimal battery pack design, converter topologies, and performance

Get Price

Lithium battery pack balancing solution design

This paper presents an integrated state-of-charge (SOC) estimation model and active cell balancing of a 12-cell lithium iron phosphate (LiFePO4) battery power system.

Get Price

TIDA-00792 reference design | TI

This reference design provides monitoring, balancing, primary protection and gauging for a 12- to 15-cell lithium-ion or lithium-iron phosphate-based batteries. This board is

Get Price

How to Achieve EV Battery Balancing?

Learn how to achieve optimal EV battery balancing with our in-depth guide- the essential techniques, tools, and best practices.

Get Price

A critical review of battery cell balancing techniques, optimal design

This optimization includes a comprehensive strategy that consist of battery cell balancing approaches, optimal battery pack design, converter topologies, and performance

Get Price

Modular balancing strategy for lithium battery pack based on

Battery balancing is crucial to potentiate the capacity and lifecycle of battery packs. This paper proposes a balancing scheme for lithium battery packs based on a ring layered

Get Price

Multicell 36-V to 48-V Battery Management System

15-cell lithium-ion or lithium-iron phosphate-based batteries. This board is intended to be mounted in an enclosure for industrial systems. The reference design subsystem provides battery

Get Price

16-Cell Lithium-Ion Battery Active Balance Reference Design

TI Designs The 16-Cell Lithium-Ion Battery Active Balance Reference Design describes a complete solution for high current balancing in battery stacks used for high voltage

Get Price

Performance Analysis of Optimized Active Cell Balancing Circuits

The increasing need for reliable and efficient energy storage solutions has brought a strong focus on enhancing the performance of lithium-ion batteries (LIBs), especially for high

Get Price

More related information

-

Lithium battery pack balancing equipment

Lithium battery pack balancing equipment

-

Lithium battery energy storage design solution

Lithium battery energy storage design solution

-

24 strings 8A lithium battery pack active balancing module

24 strings 8A lithium battery pack active balancing module

-

Malaysia 48v 13 strings lithium battery pack

Malaysia 48v 13 strings lithium battery pack

-

Fengyu rechargeable lithium battery pack

Fengyu rechargeable lithium battery pack

-

New lithium iron phosphate battery pack factory in St Lucia

New lithium iron phosphate battery pack factory in St Lucia

-

Lithium battery pack operating voltage

Lithium battery pack operating voltage

-

Bahamas lithium battery pack customization

Bahamas lithium battery pack customization

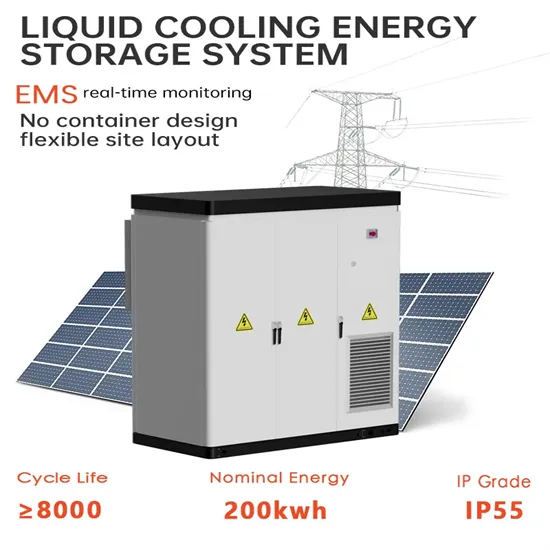

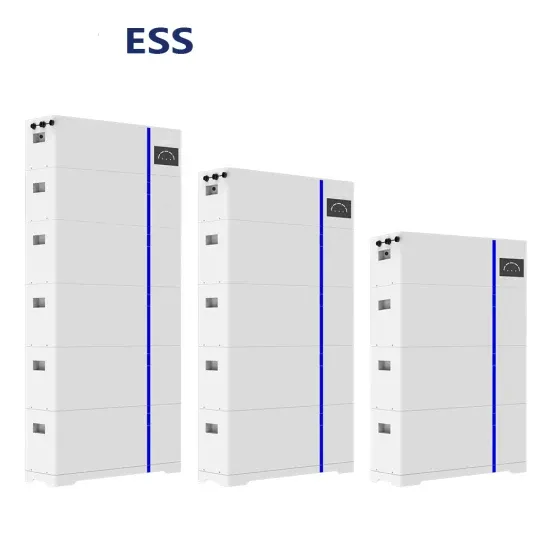

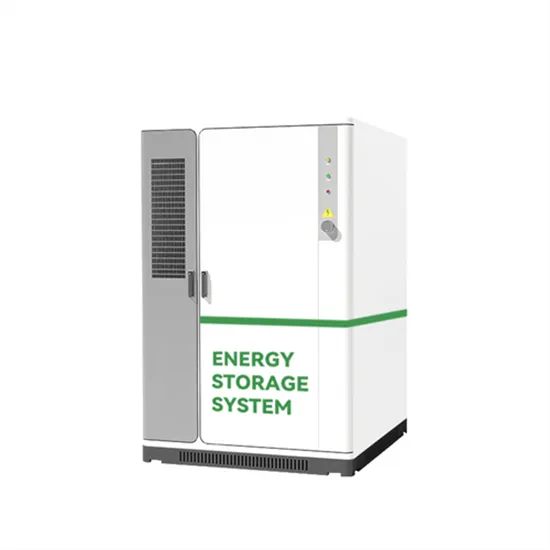

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.