Lithium Battery Pack Designer

About Our Battery Pack Designer Our battery pack designer tool is a web-based application that helps engineers and DIYers build custom DIY battery packs various electronic devices or

Get Price

Designing a Battery Pack?

Starting out in Battery Design? Check out Battery Basics as this will walk you through from chemistry to pack. More advanced and you want to dive into a particular aspect of the design

Get Price

Designing a Battery Pack?

Starting out in Battery Design? Check out Battery Basics as this will walk you through from chemistry to pack. More advanced and you want to dive into a

Get Price

Complete Guide to Lithium Battery Pack Design and Assembly

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get Price

Battery Pack Design: Efficient & Safe Energy Storage

Learn how to design a high-performance battery pack with the right cell configuration, cooling system, and safety features.

Get Price

How to design battery packs, tutorial for Design Engineers

April 21, 2023 Engineering Guidelines for Designing Battery Packs Custom design and manufacture of state-of-the-art battery chargers, battery packs, UPS, and power supplies

Get Price

Battery Pack Simulation Models

Create battery pack models in minutes - all cell types, including cooling, customizable. The Batemo Pack Designer is the solution!

Get Price

Battery Design Explained: From Prototyping to Certification

Learn how to design efficient, compliant battery packs for drones, robotics, medical devices, and e-mobility. Explore chemistries, BMS, certification, performance

Get Price

Battery Pack Design: Efficient & Safe Energy Storage | TERTRON

Learn how to design a high-performance battery pack with the right cell configuration, cooling system, and safety features.

Get Price

Telecom Base Station Backup Power Solution: Design

This guide outlines the design considerations for a 48V 100Ah LiFePO4 battery pack, highlighting its technical advantages, key design

Get Price

Lithium Battery Pack Designer

This tool streamlines the battery pack design process by providing a range of features and functionalities to assist in the design and optimization of battery packs.

Get Price

The 7 Best Portable Power Stations of 2025

Bring big backup power with you with these expert-recommended portable power stations, which can store enough power to charge electronics, appliances, and more.

Get Price

Busbar choices for EV power distribution

Low-inductance busbars can help achieve low-loss transfer of energy with high energy efficiency from a battery pack, by minimizing energy

Get Price

Battery Pack Designer''s Guide: From Beginner to Pro [With

Battery pack design requires understanding both fundamental electrochemistry and application-specific engineering requirements. Custom battery pack applications have expanded

Get Price

Overview of Telecom Base Station Batteries

Definition Telecom base station battery is a kind of energy storage equipment dedicatedly designed to provide backup power for telecom base stations, applied to supply continuous and

Get Price

How to design a battery pack?

In the battery pack design process. You''ll explore the different factors that need to be considered, from the type of battery cells to the size and shape of the pack.

Get Price

Telecom Base Station Backup Power Solution: Design Guide for

This guide outlines the design considerations for a 48V 100Ah LiFePO4 battery pack, highlighting its technical advantages, key design elements, and applications in telecom

Get Price

Li5k Base Battery Station

The Li5k Base-S Battery Station is designed specifically for the needs of heavy-duty applications. Providing 5000 watt-hours of energy from long-lasting LFP

Get Price

How to design battery packs, tutorial for Design Engineers

The idea is that you want to design your pack so that the voltage swing of the batteries (see below) is adequate, and where the power consumption is the least.

Get Price

ESS''s Battery Pack Design Checklist: Your Roadmap to Smarter Battery

Streamline your battery pack development with ESS''s Battery Pack Design Checklist. Learn how to integrate safety, reliability and performance into every subsystem from

Get Price

Mechanical Design of Battery Packs

It further delves into the mechanical design aspects, including the weight of the battery, the forces acting on it, and the material selection for the base plate. The lesson uses the example of

Get Price

Lithium Battery for 5G Base Stations Market

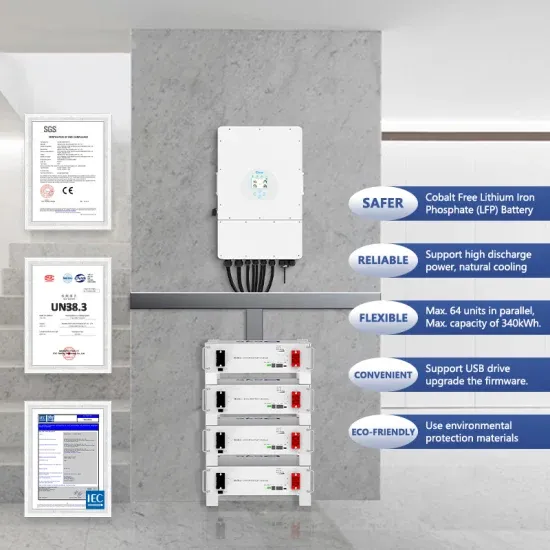

A 5G base station battery pack might use lithium iron phosphate (LFP) chemistry, which eliminates cobalt and nickel, lowering costs to $95–$110 per kWh while maintaining

Get Price

Tesla''s 4680 Battery Pack Design Evolution

Discover how Tesla''s new 4680 battery pack slashes cost, boosts range, and transforms EV design through innovative architecture.

Get Price

ESS''s Battery Pack Design Checklist: Your Roadmap

Streamline your battery pack development with ESS''s Battery Pack Design Checklist. Learn how to integrate safety, reliability and

Get Price

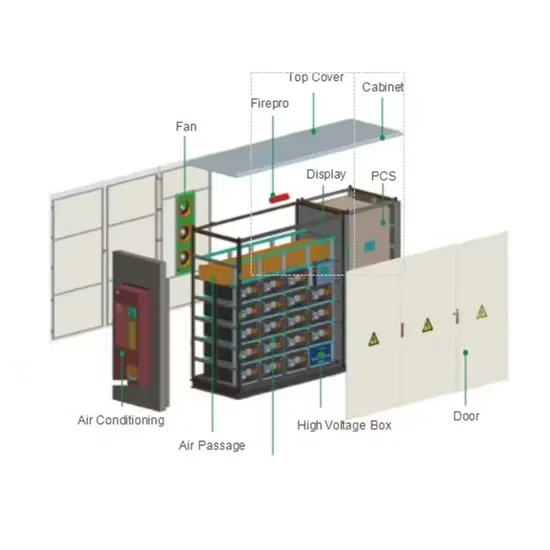

Utility-scale battery energy storage system (BESS)

BESS design IEC - 4.0 MWh system design — How should system designers lay out low-voltage power distribution and conversion for a battery energy storage system (BESS)? In this white

Get Price

Design and optimization of electric vehicle battery swapping stations

Research papers Design and optimization of electric vehicle battery swapping stations with integrated storage for enhanced efficiency☆, ☆☆

Get Price

6 FAQs about [Designing a base station battery pack]

How to design a battery pack?

As a battery pack designer it is important to understand the cell in detail so that you can interface with it optimally. It is interesting to look at the Function of the Cell Can or Enclosure and to think about the relationship between the Mechanical, Electrical and Thermal design.

How to build a battery system?

Building a battery system is challenging. At the beginning everything is possible: changing pack dimensions, using different cells or varying pack cooling. To cope with the complexity, a two-step approach is very advantageous. Create your design bottom-up. Go from cell to module and pack within minutes. Put your design to the test.

What is a battery pack design tool?

This tool streamlines the battery pack design process by providing a range of features and functionalities to assist in the design and optimization of battery packs. This is V1 of the tool, it's not perfect, it's not super pretty but it's extremely helpful.

What makes a telecom battery pack compatible with a base station?

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery pack’s output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

How to design a battery pack for electric vehicles?

When you think about designing a battery pack for electric vehicles you think at cell, module, BMS and pack level. However, you need to also rapidly think in terms of: electrical, thermal, mechanical, control and safety. Looking at the problem from different angles will help to ensure you don’t miss a critical element.

How do you analyze a battery pack?

Pack Cooling Analysis: Understand the consequences of using different cooling methods in your battery pack. Price Analysis: Estimate the price impact of changes in your battery pack design. Sensitivity Analysis: Quantify how battery pack parameter variations impact you design targets.

More related information

-

Base station battery pack solar energy

Base station battery pack solar energy

-

Integrated base station lead-acid battery pack

Integrated base station lead-acid battery pack

-

Vatican Base Station Energy Storage Battery Prices

Vatican Base Station Energy Storage Battery Prices

-

Signal tower base station battery manufacturer

Signal tower base station battery manufacturer

-

United Arab Emirates base station energy storage battery cabinet

United Arab Emirates base station energy storage battery cabinet

-

Communication base station uses lithium iron phosphate battery

Communication base station uses lithium iron phosphate battery

-

New Energy Lithium Battery Site Cabinet Base Station Energy Application

New Energy Lithium Battery Site Cabinet Base Station Energy Application

-

Home Solar Base Station Battery

Home Solar Base Station Battery

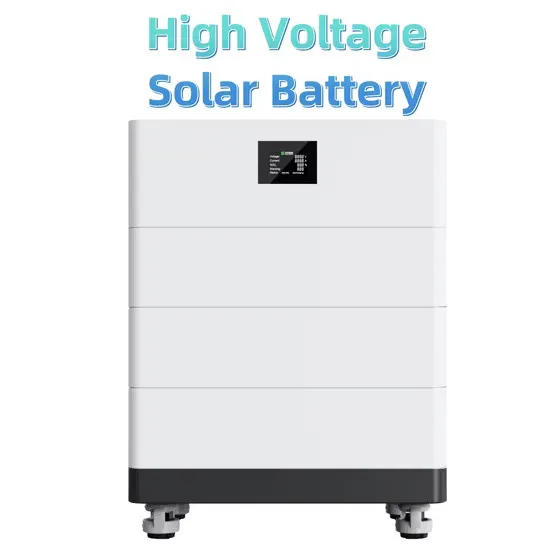

Commercial & Industrial Solar Storage Market Growth

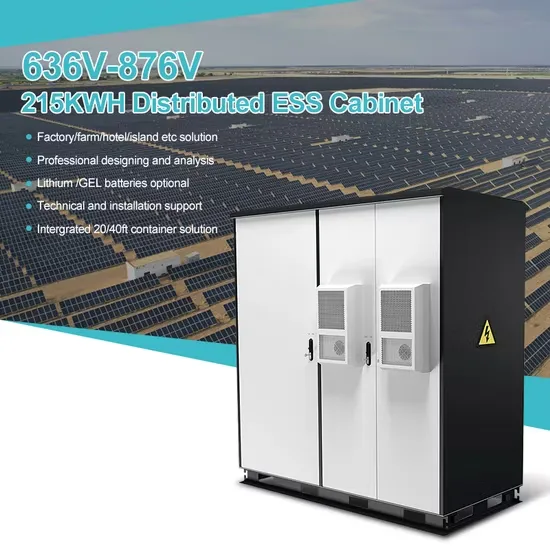

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.