Solar energy and the environment

Solar energy technologies and power plants do not produce air pollution or greenhouse gases when operating. Using solar energy can have a positive, indirect effect on the environment

Get Price

8 Major Raw Materials Used for Making Solar Panels

Here are the eight essential components that make up a solar PV module: 1. Aluminum Alloy Frames. Regarding solar panels, we usually consider the

Get Price

The Hidden Hazards of Solar Panel Cleaning (and How to Avoid

Solar has a dirty little secret: Your panels could be producing 30% more energy. We break down how to clean your panels - the right way - to safely and efficiently maximize your solar

Get Price

Solar Photovoltaic Manufacturing Basics

Polysilicon is commonly manufactured using methods that rely on highly reactive gases, synthesized primarily using metallurgical-grade silicon (obtained from

Get Price

What Are Solar Panels Made Of? A Guide to 7 Key Materials

In this article, we look at solar panel raw materials that used to make solar panels. We look at the raw materials of a PV module including busbars, and junction boxes to the cell

Get Price

Materials for solar fuels and chemicals

The conversion of sunlight into fuels and chemicals is an attractive prospect for the storage of renewable energy, and photoelectrocatalytic technologies represent a pathway by

Get Price

Solar Chemicals

As the world''s leading chemical company, we cover the entire production process for solar cells and panels; from cutting the silicon ingots to metallization to frame fabrication. More efficiency

Get Price

What Chemicals Are Used to Make Solar Panels?

Solar panels use various chemicals during manufacturing, from silicon processing to encapsulation. Discover what chemicals are used to

Get Price

⚡ 90% of Solar Panels Aren''t Producing Their Full Power

4 days ago· Solar Cleaning Starting at $199 ⚡ 90% of Solar Panels Aren''t Producing Their Full Power — Is Yours One of Them? Most solar owners think their system is working at 100%.

Get Price

What Are Solar Panels Made Of and How Are They Made?

Most panels on the market are made of monocrystalline, polycrystalline, or thin film ("amorphous") silicon. In this article, we''ll explain how solar cells are made and what parts are

Get Price

What Are Solar Panels Made Of? A Guide to 7 Key

In this article, we look at solar panel raw materials that used to make solar panels. We look at the raw materials of a PV module including

Get Price

Common Chemicals Used for Solar Energy

From solar panel production to the solar conversion process itself, there are a number of common chemicals utilized – some of which may come as a surprise. So, what

Get Price

Key Chemicals for Solar Panel Manufacturing and Thermal

When diving into the world of Wet Electronic Chemicals for Solar Panel, there''s no shortage of questions, curiosity, and discoveries. This article aims to unpack key insights while

Get Price

7 Best Biodegradable Cleaning Options for Solar

Keeping your solar panels clean is essential for maintaining peak energy production, but many traditional cleaning products contain harsh

Get Price

Solar chemical – Knowledge and References – Taylor & Francis

Solar chemical refers to the process of using solar energy to directly convert it into chemical energy, such as hydrogen production or the reduction of CO2 and water splitting through the

Get Price

8 Major Raw Materials Used for Making Solar Panels

Here are the eight essential components that make up a solar PV module: 1. Aluminum Alloy Frames. Regarding solar panels, we usually consider the most fundamental raw materials: the

Get Price

Key Chemicals for Solar Panel Manufacturing and Thermal

These chemicals—often in ACS or semiconductor-grade formulations—can be found across multiple Alliance Chemical categories (e.g., acids, bases and caustics, other

Get Price

What Are Solar Panels Made Of and How Are They

Most panels on the market are made of monocrystalline, polycrystalline, or thin film ("amorphous") silicon. In this article, we''ll explain

Get Price

What are solar panels made of? [Materials

Discover the key materials that make up modern monocrystalline solar panels, what role each material plays, and where these materials usually

Get Price

What toxic materials are commonly found in solar panels

Common toxic materials found in solar panels primarily include heavy metals such as lead, cadmium, arsenic, selenium, and sometimes silver and copper. These materials are

Get Price

What Chemicals Are Used to Make Solar Panels?

Solar panels use various chemicals during manufacturing, from silicon processing to encapsulation. Discover what chemicals are used to make solar panels.

Get Price

Key Chemicals for Solar Panel Manufacturing and

These chemicals—often in ACS or semiconductor-grade formulations—can be found across multiple Alliance Chemical categories

Get Price

Solar Photovoltaic Manufacturing Basics

Polysilicon is commonly manufactured using methods that rely on highly reactive gases, synthesized primarily using metallurgical-grade silicon (obtained from quartz sand), hydrogen,

Get Price

Dark Side To Solar? More Reports Tie Panel

A major new study of the economics of solar, published in Harvard Business Review, finds that the waste produced by solar panels will make

Get Price

Chinese petrochemical firms bet big on energy

Chinese oil refiners and petrochemical companies are investing tens of billions of dollars to produce high-end chemicals for solar panels and

Get Price

What chemicals are used in solar panels?

Chemicals such as hydrochloric acid, silicon tetrachloride, cadmium, and other heavy metals are used in the production of solar panels, and their disposal can have a

Get Price

What chemicals are used in solar panels?

Silicon is the most commonly used material in solar panels. The production of silicon involves several chemicals, including hydrochloric acid, which is used to purify the

Get Price

solarindustrymag

Quickly create professional logos, no design skills needed. Let AI help you save time and money on a unique logo for your business, with options for custom fonts, 3D artwork, and more.

Get Price

What Are Solar Panels Made Of and How Are They

Answering that question means understanding how solar energy works, how solar panels are manufactured, and what the parts of a solar panel

Get Price

More related information

-

What are the three major equipments for producing solar panels

What are the three major equipments for producing solar panels

-

The cost of purchasing solar photovoltaic panels in Uruguay

The cost of purchasing solar photovoltaic panels in Uruguay

-

Photovoltaic thin film battery conductive solar panels

Photovoltaic thin film battery conductive solar panels

-

Huawei Belgium energy storage power generation solar panels

Huawei Belgium energy storage power generation solar panels

-

Where to sell solar panels

Where to sell solar panels

-

East Asia Solar Panels

East Asia Solar Panels

-

Are bifacial solar panels reliable

Are bifacial solar panels reliable

-

Solar photovoltaic panels using farmland

Solar photovoltaic panels using farmland

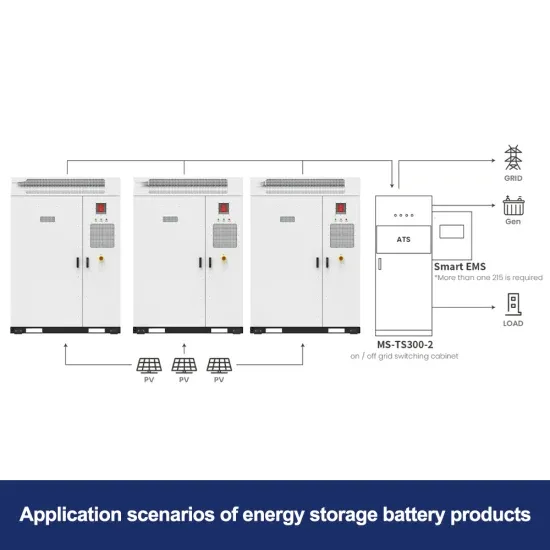

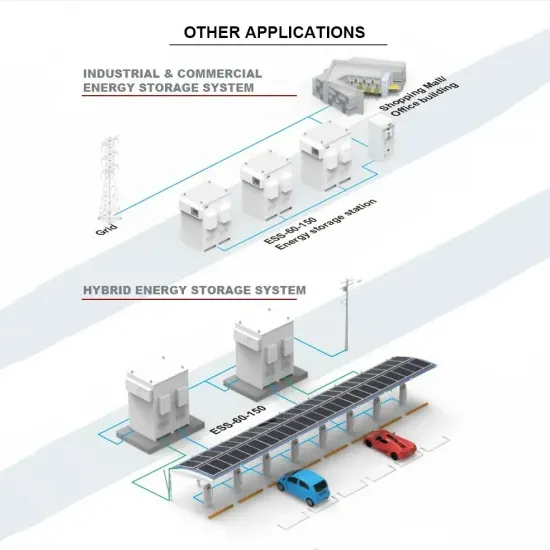

Commercial & Industrial Solar Storage Market Growth

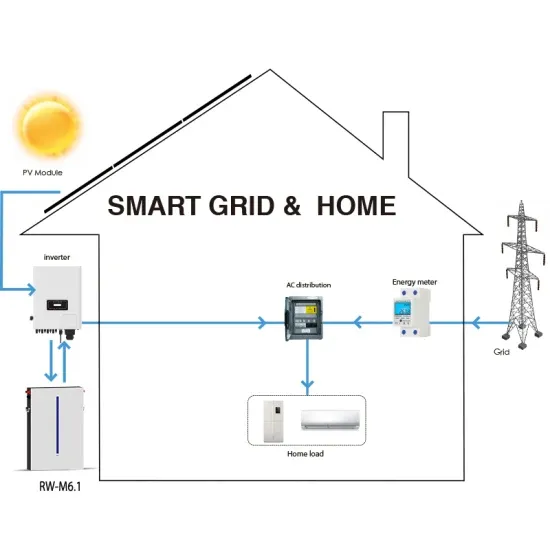

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

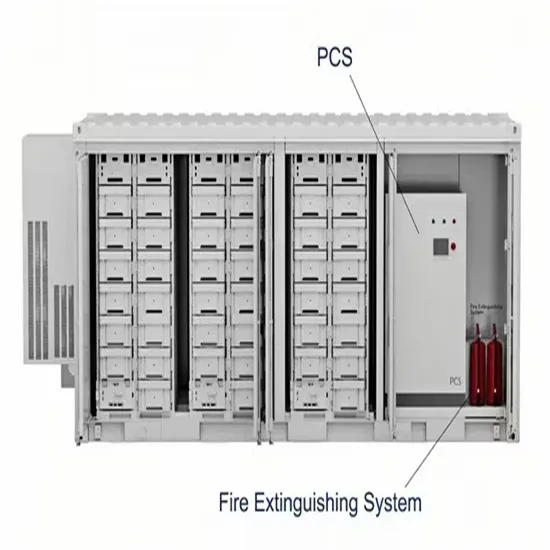

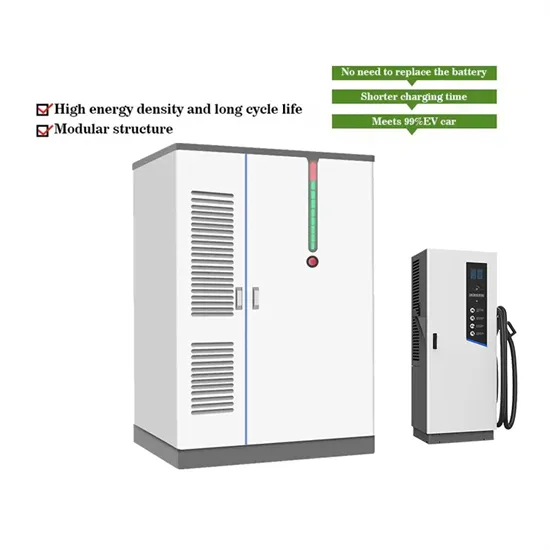

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.