What Are Liquid Flow Batteries And Their Advantages?

Liquid flow batteries provide high capacity, safety, and eco-friendliness, ideal for large-scale energy storage and operation in harsh

Get Price

Sodium-Ion Batteries: What You Need to Know? | IMI

What are sodium-ion batteries? Sodium-ion batteries use sodium ions instead of lithium to store and release energy through a liquid electrolyte.

Get Price

What Are Liquid Flow Batteries And Their Advantages?

Liquid flow batteries provide high capacity, safety, and eco-friendliness, ideal for large-scale energy storage and operation in harsh environments

Get Price

Advancements and challenges in sodium-ion batteries: A

Sodium-ion batteries offer a compelling solution due to the abundance of sodium, cost-effectiveness, and compatibility with existing battery production infrastructure.

Get Price

Progress in safe nano-structured electrolytes for sodium ion

Furthermore, Build Your Dreams (BYD), a pioneer in battery technology and an electric vehicle manufacturing company in China, has recently announced the building of a

Get Price

New Flow Battery Deploys Salt For Long Duration

Statkraft is evaluating a new flow battery based on table salt to pull more wind and solar power into the grid.

Get Price

An overview of sodium-ion batteries as next-generation

Through this paper, the current state of Na-ion batteries, focusing on key components such as anodes, electrolytes, cathodes, binders, separators, and current collectors, has been critically

Get Price

liquid flow sodium ion energy storage battery

A sodium–sulfur (NaS) battery is a type of molten-salt battery that uses liquid sodium and liquid sulfur electrodes. [1] [2] This type of battery has a similar energy density to lithium-ion

Get Price

Lithium-ion flow battery

A lithium-ion flow battery is a flow battery that uses a form of lightweight lithium as its charge carrier. [1] The flow battery stores energy separately from its system for discharging.

Get Price

A new sodium-ion battery breakthrough means they

Sodium-ion battery performance has been limited because of poor durability, but this is about to change for the better.

Get Price

The Sodium Battery Landscape

In June 2025, an MIT-led team reported a liquid-sodium/air fuel cell that uses a Na-βʺ-alumina solid electrolyte and humidified air, so the sodium-hydroxide discharge product

Get Price

New solid-state sodium batteries enable lower cost

Conversely, sodium-ion batteries provide a more sustainable alternative due to the tremendous abundance of salt in our oceans, thereby

Get Price

Molten-salt battery

Sodium–sulfur The sodium–sulfur battery (NaS battery), along with the related lithium–sulfur battery employs cheap and abundant electrode materials. It was the first alkali-metal

Get Price

Cheaper, Faster, Cleaner: Scientists Have Developed

Credit: Laboratory for Energy Storage and Conversion New Architectural Innovations To create a sodium battery with the energy density

Get Price

Sodium-ion battery vs. redox flow

Two promising solutions are the sodium-ion battery and the redox flow battery. Both offer specific advantages, but which is the better choice? In this article, we compare the

Get Price

New Flow Battery Deploys Salt For Long Duration Energy Storage

Statkraft is evaluating a new flow battery based on table salt to pull more wind and solar power into the grid.

Get Price

Aqueous Rechargeable Sodium-Ion Batteries: From

Sodium-ion batteries stand out as a promising technology for developing a new generation of energy storage devices because of their

Get Price

Sodium-ion batteries: All you need to know

Sodium-ion batteries are a promising new battery technology with the potential to address many of the limitations of lithium-ion batteries. This

Get Price

Comprehensive review of Sodium-Ion Batteries: Principles,

Sodium-ion batteries (SIBs) are emerging as a viable alternative to lithium-ion batteries (LIBs) due to their cost-effectiveness, abundance of sodium resources, and lower

Get Price

DOE ESHB Chapter 4: Sodium-Based Battery Technologies

Abstract The growing demand for low-cost electrical energy storage is raising significant interest in battery technologies that use inexpensive sodium in large format storage systems.

Get Price

Sodium batteries: The technology of the future?

The anode, the negative pole of the battery, is made up of anode material (e.g. carbon or graphite) and the current collector. A sodium cell is

Get Price

Sodium–sulfur battery

Sodium–sulfur battery Cut-away schematic diagram of a sodium–sulfur battery A sodium–sulfur (NaS) battery is a type of molten-salt battery that uses liquid sodium and liquid sulfur

Get Price

A promising new kind of battery is based on sodium,

For this prototype, postdoctoral scholar Min Ah Lee and the Stanford team improved how sodium and myo-inositol enable that electron flow,

Get Price

An overview of sodium-ion batteries as next

Through this paper, the current state of Na-ion batteries, focusing on key components such as anodes, electrolytes, cathodes, binders, separators, and

Get Price

Technology Strategy Assessment

Much of the attraction to sodium (Na) batteries as candidates for large-scale energy storage stems from the fact that as the sixth most abundant element in the Earth''s crust and the fourth

Get Price

A promising new kind of battery is based on sodium, not lithium

For this prototype, postdoctoral scholar Min Ah Lee and the Stanford team improved how sodium and myo-inositol enable that electron flow, significantly boosting the performance

Get Price

6 FAQs about [Liquid Flow Battery Sodium Ion Battery]

What is a saltwater flow battery?

In an era where grid-scale energy storage is essential for the transition to renewable energy, Salgenx is proud to announce its Saltwater Flow Battery, a groundbreaking solution that eliminates the safety risks and environmental challenges associated with lithium-ion batteries.

What is a sodium ion battery?

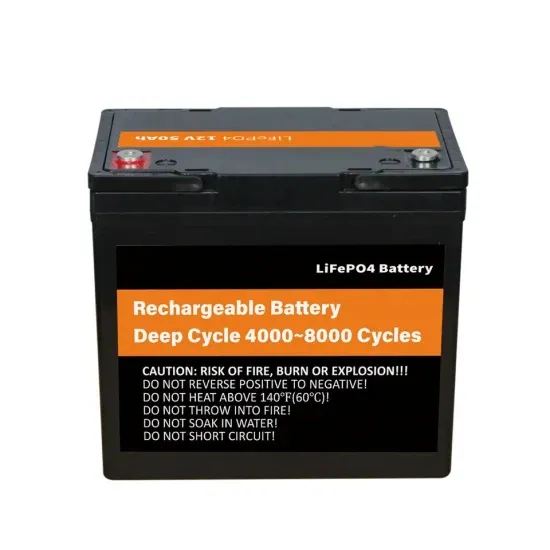

Sodium-ion batteries (NaIBs) were initially developed at roughly the same time as lithium-ion batteries (LIBs) in the 1980s; however, the limitations of charge/discharge rate, cyclability, energy density, and stable voltage profiles made them historically less competitive than their lithium-based counterparts .

Are sodium ion batteries a viable alternative to lithium-ion battery?

Innovations in electrolytes and cell designs improve cycle life and Coulombic efficiency. Sodium-ion batteries (SIBs) are emerging as a viable alternative to lithium-ion batteries (LIBs) due to their cost-effectiveness, abundance of sodium resources, and lower environmental impact.

Are sodium ion batteries a good choice?

Challenges and Limitations of Sodium-Ion Batteries. Sodium-ion batteries have less energy density in comparison with lithium-ion batteries, primarily due to the higher atomic mass and larger ionic radius of sodium. This affects the overall capacity and energy output of the batteries.

Are sodium-ion batteries the future of energy storage?

Material testing suggests sodium-ion batteries could be 20% cheaper, with stable material costs expected over time, making them a promising alternative for the future of energy storage. Thermal analysis shows sodium-ion batteries perform better than lithium-ion in cold conditions. CATL’s new batteries work in temperatures as low as -40°F.

How do sodium ion batteries work?

During discharge, the ions travel back to the cathode, releasing stored energy.The cathode materials, such as Prussian blue analogues (PBAs), are highly suited for sodium-ion batteries because of their open framework structure and large interstitial spaces, which can accommodate the relatively larger sodium ions.

More related information

-

How big is the liquid flow battery in mobile base station equipment

How big is the liquid flow battery in mobile base station equipment

-

Korean liquid flow battery

Korean liquid flow battery

-

Panama energy liquid flow battery

Panama energy liquid flow battery

-

Liquid flow battery

Liquid flow battery

-

Saint Kitts and Nevis all-vanadium liquid flow battery energy storage

Saint Kitts and Nevis all-vanadium liquid flow battery energy storage

-

All-vanadium liquid flow battery industrial energy storage

All-vanadium liquid flow battery industrial energy storage

-

New Zealand all-vanadium liquid flow battery

New Zealand all-vanadium liquid flow battery

-

Colombian New Energy All-vanadium Liquid Flow Battery

Colombian New Energy All-vanadium Liquid Flow Battery

Commercial & Industrial Solar Storage Market Growth

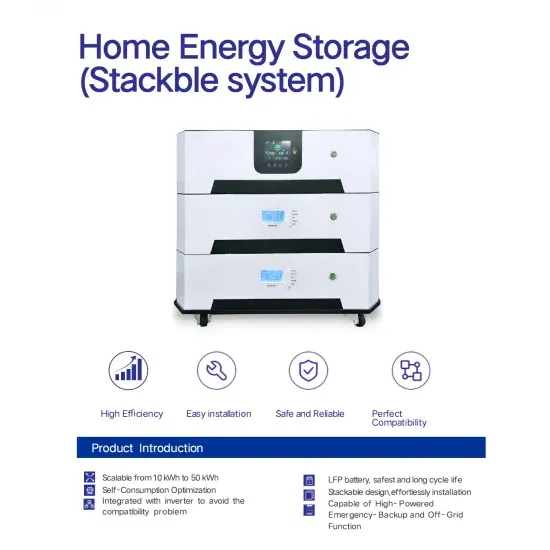

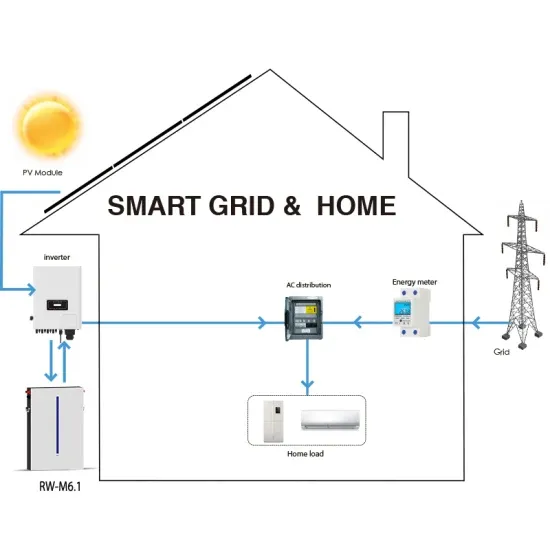

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.