Vanadium Redox-Flow Battery

As the schematic shown in Fig. 1, a vanadium redox-flow battery has two chambers, a positive chamber and a negative chamber, separated by an ion-exchange membrane.

Get Price

Vanadium Redox Flow Battery Stack Balancing to

This experimental study was conducted on a 10 kW uninterruptible power supply system based on two 5 kW stacks of all-vanadium redox flow

Get Price

A Review of Capacity Decay Studies of All‐vanadium

This review generally overview the problems related to the capacity attenuation of all-vanadium flow batteries, which is of great significance for

Get Price

Research progress in preparation of electrolyte for all-vanadium redox

All-vanadium redox flow battery (VRFB), as a large energy storage battery, has aroused great concern of scholars at home and abroad. The electrolyte, as the active material

Get Price

A Review of Capacity Decay Studies of All‐vanadium Redox Flow

This review generally overview the problems related to the capacity attenuation of all-vanadium flow batteries, which is of great significance for understanding the mechanism

Get Price

Vanadium redox flow batteries real-time State of Charge and

Although several types of redox flow batteries are being investigated, at the moment, the All-Vanadium Redox Flow Battery (VRFB) is the most mature [6]. By using only

Get Price

(PDF) A Review of Capacity Decay Studies of All

As a promising large‐scale energy storage technology, all‐vanadium redox flow battery has garnered considerable attention.

Get Price

(PDF) A Review of Capacity Decay Studies of All-vanadium Redox Flow

As a promising large‐scale energy storage technology, all‐vanadium redox flow battery has garnered considerable attention. However, the issue of capacity decay significantly

Get Price

Enhancing the performance of all-vanadium redox flow batteries

An all-vanadium redox flow battery (VRFB) is an attractive candidate as an electrochemical energy storage system that uses conversion technology for applications that

Get Price

All-vanadium redox flow batteries

The most commercially developed chemistry for redox flow batteries is the all-vanadium system, which has the advantage of reduced effects of species crossover as it

Get Price

Vanadium Redox Flow Battery Stack Balancing to Increase

This experimental study was conducted on a 10 kW uninterruptible power supply system based on two 5 kW stacks of all-vanadium redox flow batteries. It was demonstrated

Get Price

Vanadium Redox-Flow Battery

As the schematic shown in Fig. 1, a vanadium redox-flow battery has two chambers, a positive chamber and a negative chamber, separated by an ion

Get Price

All-soluble all-iron aqueous redox flow batteries: Towards

All-iron aqueous redox flow batteries (AI-ARFBs) are attractive for large-scale energy storage due to their low cost, abundant raw materials, and the safety and

Get Price

A Review of Capacity Decay Studies of All‐vanadium Redox Flow

As a promising large-scale energy storage technology, all-vanadium redox flow battery has garnered considerable attention. However, the issue of capacity decay significantly

Get Price

Comprehensive Analysis of Critical Issues in All-Vanadium Redox Flow

Then, a comprehensive analysis of critical issues and solutions for VRFB development are discussed, which can effectively guide battery performance optimization and

Get Price

Development status, challenges, and perspectives of key

All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the characteristics of

Get Price

Unravel crystallization kinetics of V(V) electrolytes for all

In this study, we illustrate the kinetics parameters of V (V) crystallization via an in situ Raman study.

Get Price

Comprehensive Analysis of Critical Issues in All

Then, a comprehensive analysis of critical issues and solutions for VRFB development are discussed, which can effectively guide battery

Get Price

Fact Sheet: Vanadium Redox Flow Batteries (October 2012)

By using one element in both tanks, VRBs can overcome cross-contamination degradation, a significant issue with other RFB chemistries that use more than one element. The energy

Get Price

A Review of Capacity Decay Studies of All-vanadium Redox Flow

This review generally overview the problems related to the capacity attenuation of all-vanadium flow batteries, which is of great significance for understanding the mechanism

Get Price

Online and noninvasive monitoring of battery health at

Abstract and Figures Hydrogen evolution is one of the major side reactions that is detrimental to the health of all-vanadium redox flow batteries,

Get Price

Vanadium redox flow batteries: A comprehensive review

Interest in the advancement of energy storage methods have risen as energy production trends toward renewable energy sources. Vanadium redox flow batt

Get Price

Unravel crystallization kinetics of V(V) electrolytes for all-vanadium

In this study, we illustrate the kinetics parameters of V (V) crystallization via an in situ Raman study.

Get Price

The World''s Largest 100MW Vanadium Redox Flow

Recently, the world''s largest 100MW/400MWh vanadium redox flow battery energy storage power station has completed the main project construction and

Get Price

Efficiency improvement of an all-vanadium redox flow battery by

In this work, the efficiency of an all-vanadium redox flow battery (VRFB) was enhanced operating the flow battery in a Thermally Regenerative Electrochemical Cycle (TREC).

Get Price

State of charge monitoring methods for vanadium redox flow battery

Highlights • New state-of-charge monitoring methods are evaluated for the all-vanadium redox flow battery. • Separate monitoring of each half-cell electrolyte allows

Get Price

Understanding the Vanadium Redox Flow Batteries

s transfer. VRB differ from conventional batteries in two ways: 1) the reaction occurs between two electrolytes, rather than between an electrolyte and an electrode, therefore no electro

Get Price

Strategies for improving the design of porous fiber felt

All-vanadium redox flow batteries (VRFBs) have emerged as a research hotspot and a future direction of massive energy storage systems

Get Price

6 FAQs about [All-vanadium redox flow battery has no attenuation]

Is all-vanadium redox flow battery a viable energy storage technology?

As a promising large-scale energy storage technology, all-vanadium redox flow battery has garnered considerable attention. However, the issue of capacity decay significantly hinders its further development, and thus the problem remains to be systematically sorted out and further explored.

What is a vanadium redox flow battery?

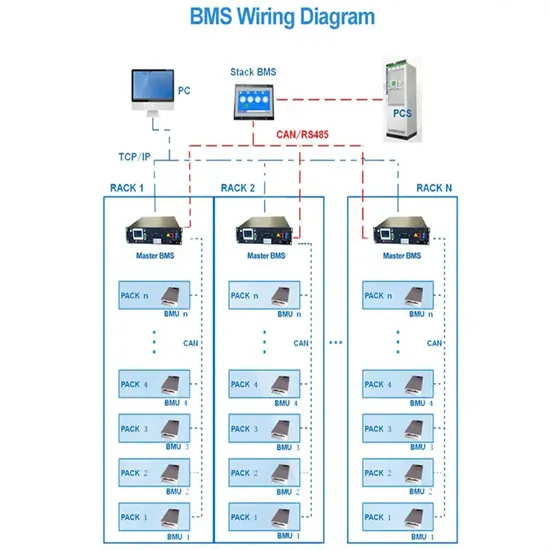

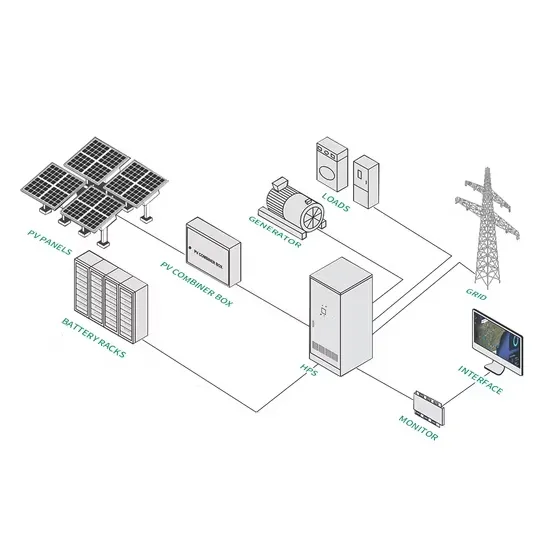

A vanadium redox flow battery consists of several basic elements: a flow cell (stack), which are fuel cells wherein an electrochemical reaction occurs; a hydrodynamic system, including pumps, flow sensors and a pressure pump control system; and electrolyte tanks [ 6 ]. Flow batteries require several stacks to achieve the desired performance [ 7 ].

What are the disadvantages of vanadium redox-flow batteries?

One disadvantage of vanadium redox-flow batteries is the low volumetric energy storage capacity, limited by the solubilities of the active species in the electrolyte. The cost of vanadium may be acceptable, because it is a relatively abundant material, which exists naturally in ~65 different minerals and fossil fuel deposits.

What factors contribute to the capacity decay of all-vanadium redox flow batteries?

Learn more. A systematic and comprehensive analysis is conducted on the various factors that contribute to the capacity decay of all-vanadium redox flow batteries, including vanadium ions cross-over, self-discharge reactions, water molecules migration, gas evolution reactions, and vanadium precipitation.

What are vanadium redox flow batteries (VRB)?

Sw tzerland1. ntroductionVanadium redox flow batteries (VRB) are large stationary electricity storage systems with many potential applications in a deregulated and decentrali ed network. Flow batteries (FB) store chemical energy and generate electricity by a redox reaction between vanadium ions dissolved in the e

What is a redox flow battery?

Redox flow batteries are distinct from Li-ion and Na-S batteries in that the former have a system architecture that includes tanks, pumps, a central reactor, etc., which is analogous to many industrial chemical processes ( Fig. 1).

More related information

-

Jordan s all-vanadium redox flow battery layout

Jordan s all-vanadium redox flow battery layout

-

All-vanadium redox flow battery discharge rate

All-vanadium redox flow battery discharge rate

-

Romanian all-vanadium redox flow battery

Romanian all-vanadium redox flow battery

-

Reduction-oxidation all-vanadium redox flow battery

Reduction-oxidation all-vanadium redox flow battery

-

American all-vanadium redox flow battery brand

American all-vanadium redox flow battery brand

-

Carbon felt in all-vanadium redox flow battery structure

Carbon felt in all-vanadium redox flow battery structure

-

Haiti all-vanadium redox flow battery

Haiti all-vanadium redox flow battery

-

Equatorial Guinea all-vanadium redox flow battery energy storage

Equatorial Guinea all-vanadium redox flow battery energy storage

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.