Research on Heat Dissipation of Cabinet of Electrochemical

During the operation of the energy storage system, the lithium-ion battery continues to charge and discharge, and its internal electrochemical reaction will inevitably generate a lot

Get Price

How to Cool an Enclosure Cabinet | Bud Industries

The key to keeping equipment cool is to remove heat from the cabinet while supplying cool air to the places that need it. Enclosure manufacturers can provide guidance to users in selecting

Get Price

Cabinet Cooling: An Essential Aspect of Energy Storage Systems

This blog post aims to explore the importance of cabinet cooling, the latest trends in this field, and the solutions available to ensure optimal performance and longevity of energy

Get Price

How to calculate the heat dissipated by a battery pack?

I have a battery pack consisting of 720 cells. I want to calculate the heat generated by it. The current of the pack is 345Ah and the pack voltage is 44.4Volts. Each cell has a

Get Price

Beat the Heat: A Comprehensive Guide to Cooling Your Entertainment Cabinet

Airflow is vital for cooling an entertainment cabinet because it helps to dissipate heat generated by the electronic devices. Without adequate airflow, heat can become trapped

Get Price

How to solve the heat dissipation problem of energy storage cabinet

To optimize the internal layout of the pre-installed energy storage power station, and to achieve the best heat ventilation and dissipation with largest energy storage capacity, we propose a

Get Price

Energy Storage Cabinet Heat Dissipation Design Drawings: The

Let''s face it - when most people picture energy storage cabinet heat dissipation design drawings, they imagine boring technical schematics. But what if I told you these blueprints hold the key

Get Price

4 Types of Heat Transfer Mechanisms for Cooling

Keeping electrical enclosures cool isn''t just desirable; it''s mission-critical. Excessive heat accelerates component degradation, causes premature

Get Price

Cooling Fans or Liquid Cooling for energy storage

With booming investment in new energy storage and industrial/commercial energy storage markets everywhere, one of the most

Get Price

Research and application of containerized energy storage thermal

Containerized energy storage systems currently mainly include several cooling methods such as natural cooling, forced air cooling, liquid cooling and phase change cooling. Natural cooling

Get Price

How to Calculate Heat Load in Electrical/Electronic Panel Enclosure

Total heat load consists of the heat transfer from outside your panel and from the heat dissipated inside the control unit.

Get Price

Battery Heat Generation Calculator

This heat is primarily due to the internal resistance of the battery, which causes energy loss in the form of heat when current flows through it. Understanding and managing

Get Price

Xu et al. analysed the influence of changes in the number of inlets and outlets of cooling channels on the heat dissipation performance, and found that the performance of Liquid-cooled

Get Price

How to dissipate heat through energy storage air cooling

Air cooling is the traditional approach to managing heat in battery systems. By circulating air through or around the batteries, this method leverages natural or forced convection to

Get Price

Research and application of containerized energy

Containerized energy storage systems currently mainly include several cooling methods such as natural cooling, forced air cooling, liquid

Get Price

Research on Heat Dissipation of Cabinet of Electrochemical Energy

During the operation of the energy storage system, the lithium-ion battery continues to charge and discharge, and its internal electrochemical reaction will inevitably generate a lot

Get Price

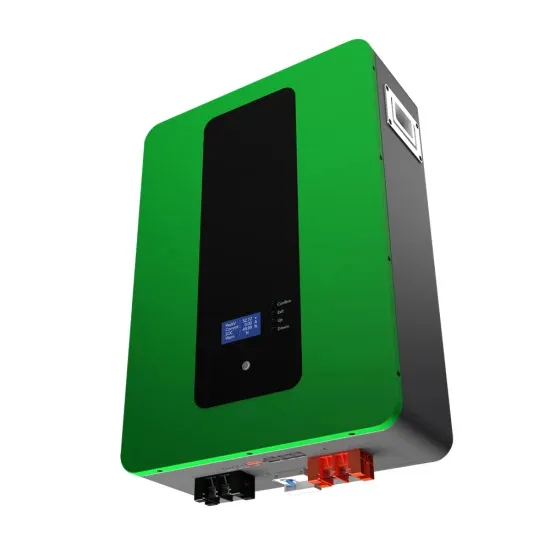

How does the energy storage battery cabinet dissipate heat?

The energy storage battery cabinet dissipates heat primarily through 1. ventilation systems, 2. passive heat sinks, 3. active cooling methods, and 4. thermal management protocols.

Get Price

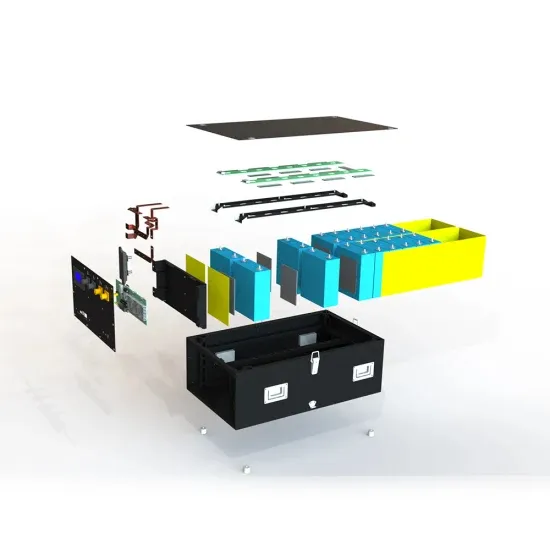

How does the new energy battery cabinet dissipate heat

Battery thermal management is becoming more and more important with the rapid development of new energy vehicles. This paper presents a novel cooling structure for cylindrical power

Get Price

What are the heat dissipation issues of energy storage cabinets?

The intricate relationship between energy generation, storage, and dissipation unveils a crucial layer of analysis—especially on how the design and material selection for

Get Price

Air Cooling vs. Liquid Cooling: The Ultimate Energy

Energy Storage Systems (ESS) are essential for a variety of applications and require efficient cooling to function optimally. This article sets

Get Price

Cabinet Cooling: A Key Aspect in Energy Storage Systems

Cabinet cooling is an indispensable part of energy storage systems. By choosing the appropriate cooling method and keeping up with the latest trends in this field, we can

Get Price

How to Calculate Heat Dissipation in Electrical

How to Calculate Heat Dissipation in Electrical Enclosures Overheating is a common reason many electrical devices fail and become unusable, but this

Get Price

The ''calm'' art of energy storage outdoor cabinets: air-cooled vs

As a key component of energy storage systems, the heat dissipation performance of outdoor energy storage cabinets directly affects the operational efficiency and lifespan of the entire

Get Price

Cooling pitch cabinets in wind turbines using a pulsating heat

Abstract As the electric capacity of wind turbine increases, heat dissipation in pitch cabinets becomes challenging owing to the limited space and rotating conditions. To cool

Get Price

Study on performance effects for battery energy storage rack in

This study simulates the working conditions of the energy storage system, taking the Design A model as an example to simulate the heat transfer process of cooling air entering

Get Price

What are the heat dissipation issues of energy storage

The intricate relationship between energy generation, storage, and dissipation unveils a crucial layer of analysis—especially on how the design

Get Price

6 FAQs about [How to dissipate heat in energy storage cabinets]

How do you remove heat from a computer?

Most systems remove heat through a combination of methods, even though one may be emphasized. For example, a processor chip may be cooled using a heat sink (conduction) that includes a fan (forced convection). The key to keeping equipment cool is to remove heat from the cabinet while supplying cool air to the places that need it.

How does cooling help with heat dissipation?

Having an effective cooling strategy can help in adequately dealing with heat dissipation. Heat transfer takes place in one of three ways: through radiation, conduction and natural or forced convection. Heat transfer via radiation occurs through electromagnetic waves, an example being the sun’s energy reaching the earth.

How does a cabinet cooler work?

A typical cabinet cooler has two heat exchangers. The interior fan draws hot air over the heat exchanger inside the cabinet and blows the cooled air back into the cabinet. The heat absorbed is transferred to an outside heat exchanger where it is cooled by the ambient air using another fan.

Why is temperature a problem in cabinets & enclosures?

Such equipment has specific operating temperature ranges and when put inside of cabinets and enclosures, temperature can become a big issue. Excessive waste heat generated by equipment within a cabinet is the single most important factor effecting equipment performance, reliability and failure.

How do enclosure manufacturers choose the best cooling methods?

Enclosure manufacturers can provide guidance to users in selecting the proper cooling approaches. The most commonly used cooling methods for enclosures, in order of increasing cost, are natural convection, forced convection (such as fans and blowers) and air conditioning.

How should a kitchen cabinet be ventilated?

The cabinet should have sufficient venting at both the top and bottom to promote airflow and a chimney effect. The best way natural airflow is circulated within a cabinet is when it is drawn from the bottom up through the top of the enclosure. Top covers can be either fixed or removable and ventilated, or non-ventilated.

More related information

-

How is the heat dissipation of photovoltaic energy storage cabinets

How is the heat dissipation of photovoltaic energy storage cabinets

-

How to calculate the discharge efficiency of energy storage cabinets

How to calculate the discharge efficiency of energy storage cabinets

-

How to match batteries with energy storage cabinets

How to match batteries with energy storage cabinets

-

How to string energy storage cabinets

How to string energy storage cabinets

-

How much is the price of new energy storage cabinets in Chad

How much is the price of new energy storage cabinets in Chad

-

How to match energy storage cabinets with photovoltaic panels

How to match energy storage cabinets with photovoltaic panels

-

How to use distributed energy storage cabinets in parallel

How to use distributed energy storage cabinets in parallel

-

How many industrial and commercial energy storage cabinets have been reported and can be constructed

How many industrial and commercial energy storage cabinets have been reported and can be constructed

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.