Charging Pile

The charging pile market is expanding rapidly due to the growing adoption of electric vehicles (EVs). Charging piles are classified into AC and DC types, catering to

Get Price

Control Strategy of Distributed Photovoltaic Storage Charging Pile

Distributed photovoltaic storage charging piles in remote rural areas can solve the problem of charging difficulties for new energy vehicles in the countryside, but these storage

Get Price

In-depth analysis of the high voltage of energy storage charging piles

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with

Get Price

High-Power Charging Piles: The Future Trend of EV Charging

This high-voltage platform can increase the operating voltage of vehicle battery systems and charging stations to 800V or even above 1000V, enabling ultra-high power output.

Get Price

An Ultra‐High Voltage AC/DC Isolated Matrix

This article proposes an ultra-high voltage AC/DC isolated matrix converter applied to V2G electric vehicle charging piles, which can achieve

Get Price

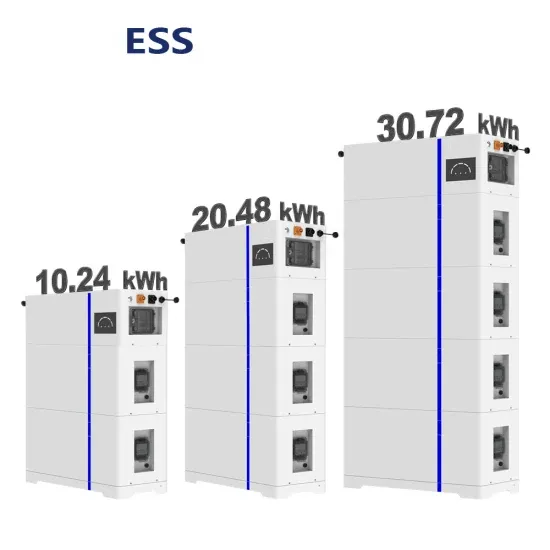

High-voltage charging pile energy storage

Absen''''s Pile high-voltage stackable residential battery is a high-performance residential energy storage solution supported by a high-voltage battery pack. It is used for storage of renewable

Get Price

XPeng Announces 480 kW Chargers And 800V SiC

To maximize the utility of the 800V SiC platform, XPeng will also roll out lightweight 480 kW high-voltage supercharging piles with IP67 protection, and

Get Price

Optimized operation strategy for energy storage charging piles

In response to the issues arising from the disordered charging and discharging behavior of electric vehicle energy storage Charging piles, as well as the dynamic

Get Price

Energy storage charging pile can withstand high voltage

Absen''''s Pile S is an all-in-one energy storage system integrating battery, inverter, charging, discharging, and intelligent control. It can store electricity converted from solar, wind and other

Get Price

What charging pile is suitable for energy storage | NenPower

1. TYPES OF CHARGING PILES Charging piles primarily come in three distinct categories: slow, fast, and ultra-fast charging stations. Each type has its specific application

Get Price

In-depth analysis of the high voltage of energy storage charging

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with

Get Price

An Ultra‐High Voltage AC/DC Isolated Matrix Converter Applied

This article proposes an ultra-high voltage AC/DC isolated matrix converter applied to V2G electric vehicle charging piles, which can achieve bidirectional flow of energy, and

Get Price

Standard range of voltage drop for energy storage charging

Can energy-storage charging piles meet the design and use requirements? The simulation results of this paper show that: (1) Enough output powercan be provided to meet the design and use

Get Price

New energy storage charging pile high voltage and low voltage

The battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage;

Get Price

EV Charger for New Energy Electric Car | VREMT

City-level Charging Facility Full-chain Solutions We provide comprehensive charging solutions covering the entire operational chain, from site survey and

Get Price

Charging Pile

Charging PileLiquid-Cooling Energy Storage System UN38.3 IEC61000 IEC62477 IEC62619IEC63056 Contact Us Home > Products > Charging Pile > Charging Pile Product

Get Price

arconstruction

The traditional charging pile management system usually only focuses on the basic charging function, which has problems such as single system function, poor user experience, and

Get Price

one-stop solution for photovoltaic storage and charging

Photovoltaic + energy storage provides multiple power backup for charging piles, which can still operate for a short period of time during power outages. The cost of photovoltaic panels and

Get Price

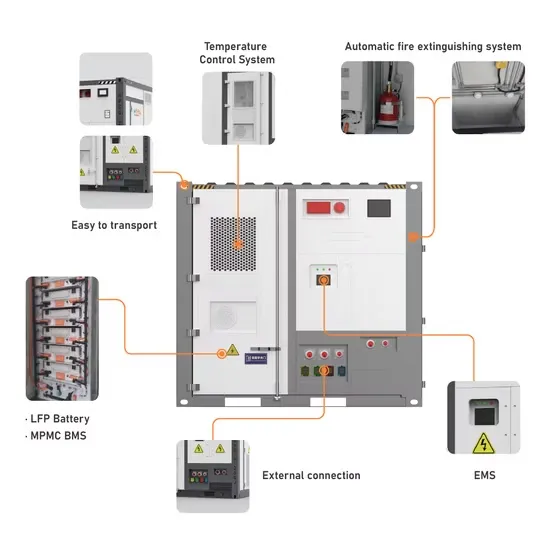

BATTERY ENERGY STORAGE SYSTEMS FOR

Reinforcing the grid takes many years and leads to high costs. The delays and costs can be avoided by buffering electricity locally in an energy storage system, such as the mtu EnergyPack.

Get Price

How about energy storage UHV charging pile | NenPower

Energy storage systems, particularly the UHV (Ultra High Voltage) charging piles, have emerged as pivotal components in this ecosystem. These technologies ensure not only

Get Price

one-stop solution for photovoltaic storage and

Photovoltaic + energy storage provides multiple power backup for charging piles, which can still operate for a short period of time during power outages. The

Get Price

Optimized operation strategy for energy storage charging piles

We have constructed a mathematical model for electric vehicle charging and discharging scheduling with the optimization objectives of minimizing the charging and

Get Price

An Ultra‐High Voltage AC/DC Isolated Matrix Converter Applied

This article proposes an ultra‐high voltage AC/DC isolated matrix converter applied to V2G electric vehicle charging piles, which can achieve bidirectional flow of energy, and

Get Price

charging pile energy storage system can be divided into four

The energy storage charging pile management system for EV is divided into three modules: energy storage charging pile equipment, cloud service platform, and mobile client. The overall

Get Price

A DC Charging Pile for New Energy Electric Vehicles

This paper introduces a high power, high efficiency, wide voltage output, and high power factor DC charging pile for new energy electric vehicles, which can be connected in

Get Price

6 FAQs about [Ultra-high voltage energy storage for charging piles]

How does the energy storage charging pile's scheduling strategy affect cost optimization?

By using the energy storage charging pile's scheduling strategy, most of the user's charging demand during peak periods is shifted to periods with flat and valley electricity prices. At an average demand of 30 % battery capacity, with 50–200 electric vehicles, the cost optimization decreased by 18.7%–26.3 % before and after optimization.

How effective is the energy storage charging pile?

The energy storage charging pile achieved energy storage benefits through charging during off-peak periods and discharging during peak periods, with benefits ranging from 699.94 to 2284.23 yuan (see Table 6), which verifies the effectiveness of the method described in this paper. Table 6.

How to reduce charging cost for users and charging piles?

Based Eq. , to reduce the charging cost for users and charging piles, an effective charging and discharging load scheduling strategy is implemented by setting the charging and discharging power range for energy storage charging piles during different time periods based on peak and off-peak electricity prices in a certain region.

Do energy storage charging pile optimization strategies reduce peak-to-Valley ratios?

The simulation results demonstrate that our proposed optimization scheduling strategy for energy storage Charging piles significantly reduces the peak-to-valley ratio of typical daily loads, substantially lowers user charging costs, and maximizes Charging pile revenue.

What is energy storage discharging power?

During peak time periods, when the remaining capacity of the energy storage system is greater than the set value, its discharging power is the energy storage discharging power. Conversely, the discharging power of the charging pile is supplied by the grid power.

What is a DC charging pile?

This DC charging pile and its control technology provide some technical guarantee for the application of new energy electric vehicles. In the future, the DC charging piles with higher power level, high frequency, high efficiency, and high redundancy features will be studied.

More related information

-

How much energy storage is suitable for charging piles

How much energy storage is suitable for charging piles

-

Sudan energy storage and charging piles

Sudan energy storage and charging piles

-

A set of photovoltaic energy storage cabinets for charging piles

A set of photovoltaic energy storage cabinets for charging piles

-

Indian companies that make energy storage charging piles

Indian companies that make energy storage charging piles

-

Why don t we use energy storage cabinets to build energy storage charging piles

Why don t we use energy storage cabinets to build energy storage charging piles

-

Can energy storage cabinet batteries be used to manufacture energy storage charging piles

Can energy storage cabinet batteries be used to manufacture energy storage charging piles

-

Charging piles and energy storage power stations

Charging piles and energy storage power stations

-

Can energy storage on charging piles be profitable

Can energy storage on charging piles be profitable

Commercial & Industrial Solar Storage Market Growth

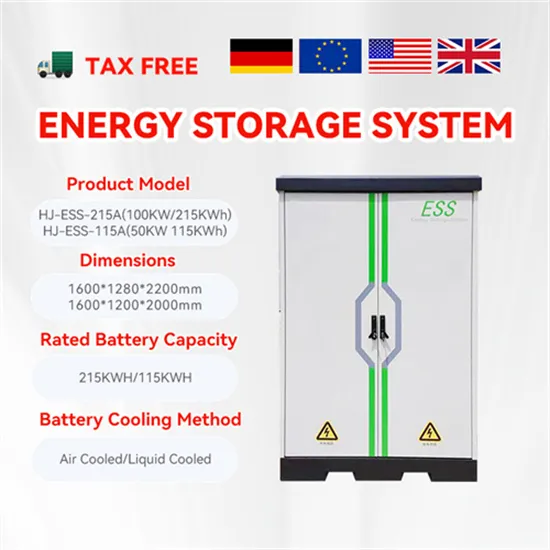

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

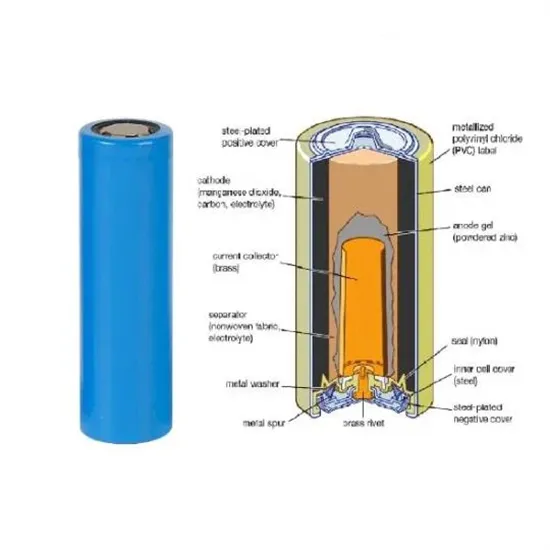

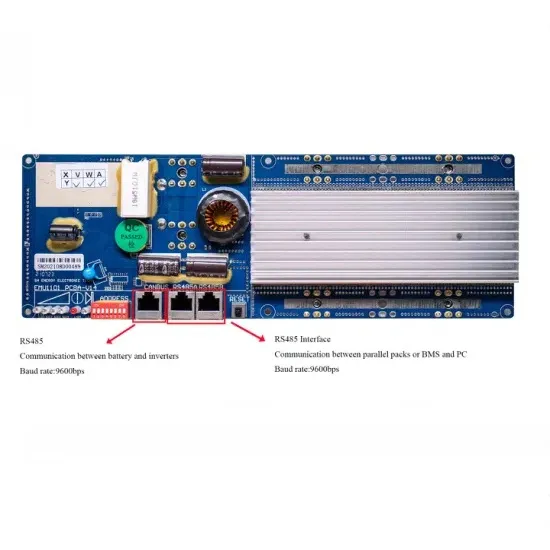

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.