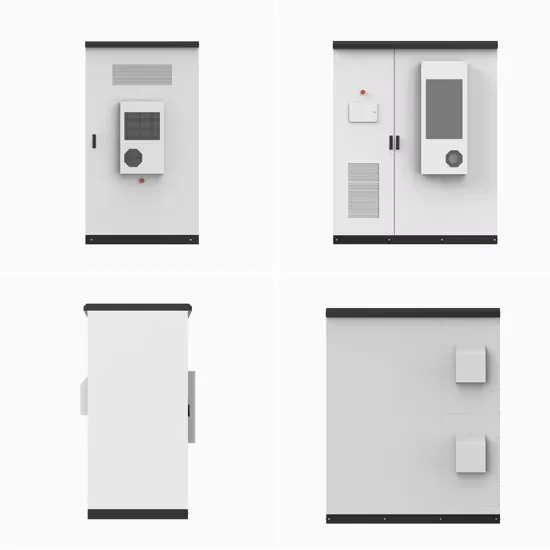

Liquid Cooling Battery Cabinet: Modern BESS Technology

Central to the performance, safety, and longevity of these advanced systems is a sophisticated thermal management solution, embodied by the modern Liquid Cooling Battery Cabinet.

Get Price

Thermal Management in Battery Systems Explained

This article explores how a thermal management system functions inside modern battery systems, particularly in industrial and commercial energy storage

Get Price

Unveiling the Industrial and Commercial Liquid-Cooled Energy

The Energy Management System (EMS) and Battery Management System (BMS) work in tandem to monitor the overall status of the cabinet 24/7, including the battery, liquid

Get Price

Types of Battery thermal management Systems

Battery thermal management systems are primarily split into three types: Active Cooling is split into three types: The cell or cells are held in an enclosure, air is forced through

Get Price

How does the battery''s thermal management system work?

Active thermal management involves using gases (including air), liquids or refrigerants to flow through all the cells in the battery to lower the temperature. Gas cooling

Get Price

Battery Thermal Management System Explained: Key

Battery thermal management systems have been systematically designed to respond to real-time temperature changes and adjust the battery''s

Get Price

Experimental and numerical investigation of a composite thermal

Therefore, it is urgent to design and develop the novel battery thermal management system (BTMS) to meet the thermal management requirements of increasing energy density

Get Price

Thermal Management Protection Solutions For

Energy storage plays an important role in the transition towards a carbon-neutral society. BESS systems depend on cooling systems that

Get Price

How It Works: Battery Thermal Management System

In liquid-cooled battery packs, coolant will flow through the battery''s BMS (Battery Management system) to transfer heat to and from the battery cells to the coolant either

Get Price

All You Need to Know About Battery Thermal Management

One of the main functions of a battery thermal management system is to extract heat from the battery to prevent the degradation of its components as well as thermal

Get Price

PERFORMANCE INVESTIGATION OF THERMAL

Energy storage like batteries is essential for stabilizing the erratic electricity supply. High temperatures when the power is charged and discharged will pro-duce high temperatures

Get Price

Battery Thermal Management: Key Solutions for Heat Control

What is Battery Thermal Management? A precision-engineered battery thermal management system (BTMS) regulates battery temperature to minimize thermal stress and

Get Price

Battery Thermal Management: Key Solutions for Heat

What is Battery Thermal Management? A precision-engineered battery thermal management system (BTMS) regulates battery temperature to

Get Price

How does the battery''s thermal management system

Active thermal management involves using gases (including air), liquids or refrigerants to flow through all the cells in the battery to lower the

Get Price

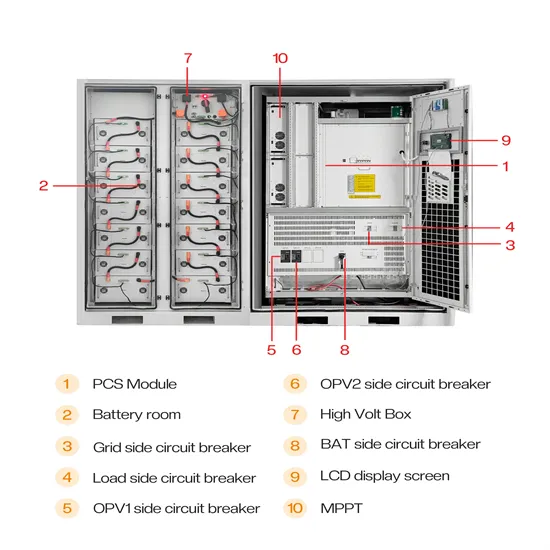

How does the energy storage battery cabinet

Every battery cabinet ideally operates under established thermal management protocols designed to prevent overheating and maintain

Get Price

How It Works: Battery Thermal Management System

In liquid-cooled battery packs, coolant will flow through the battery''s BMS (Battery Management system) to transfer heat to and from the

Get Price

Thermal Management in Battery Systems Explained-Pknergypower

This article explores how a thermal management system functions inside modern battery systems, particularly in industrial and commercial energy storage applications.

Get Price

How does the energy storage battery cabinet dissipate heat?

Every battery cabinet ideally operates under established thermal management protocols designed to prevent overheating and maintain performance. These protocols

Get Price

Battery Thermal Management System Explained: Key To Battery

Battery thermal management systems have been systematically designed to respond to real-time temperature changes and adjust the battery''s thermal condition to

Get Price

A comprehensive review of battery thermal management systems

This study explores thermal management strategies for Battery Thermal Management Systems (BTMS) in electric vehicles, with a main emphasis on enhancing

Get Price

Types of Battery thermal management Systems

Battery thermal management systems are primarily split into three types: Active Cooling is split into three types: The cell or cells are held in an

Get Price

What Is Battery Liquid Cooling and How Does It Work?

Battery thermal management systems impact vehicle safety and performance. Electric vehicle owners want to be reassured about their cars'' reliability and

Get Price

Battery Thermal Management

Battery thermal management isn''t just about cooling; it''s a sophisticated balance of heat extraction, insulation, and even heating in cold climates. While many assume batteries

Get Price

The Complete Guide to Battery Thermal Management System

Battery thermal management relies on liquid coolants capturing heat from battery cells and transferring it away through a closed-loop system. As batteries generate heat during

Get Price

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs and energy storage.

Get Price

How It Works: Battery Thermal Management System

A Battery Thermal Management System helps to maintain a battery pack within its temperature range of 20o to 45oC regardless of

Get Price

Energy storage cabinet thermal management system

The battery energy storage system is installed in a container-type structure, with built-in monitoring system, automatic fire protection system, temperature control system, energy

Get Price

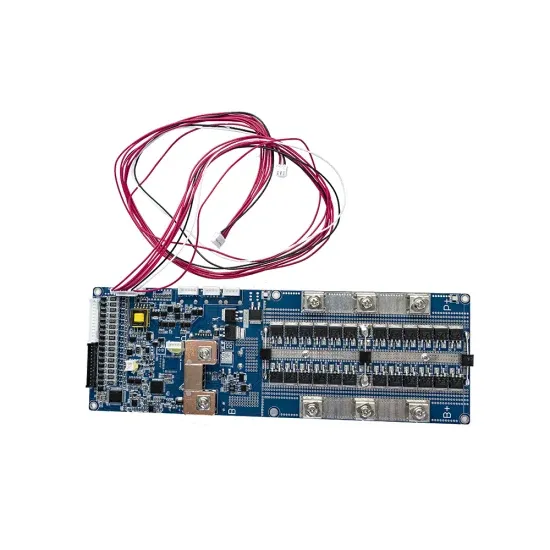

How a BMS Works with a BTMS

To ensure a vehicle operates at its optimal performance, a Battery Management System (BMS) and Battery Thermal Management System

Get Price

All You Need to Know About Battery Thermal

One of the main functions of a battery thermal management system is to extract heat from the battery to prevent the degradation of its

Get Price

6 FAQs about [How the Battery Cabinet Thermal Management System Works]

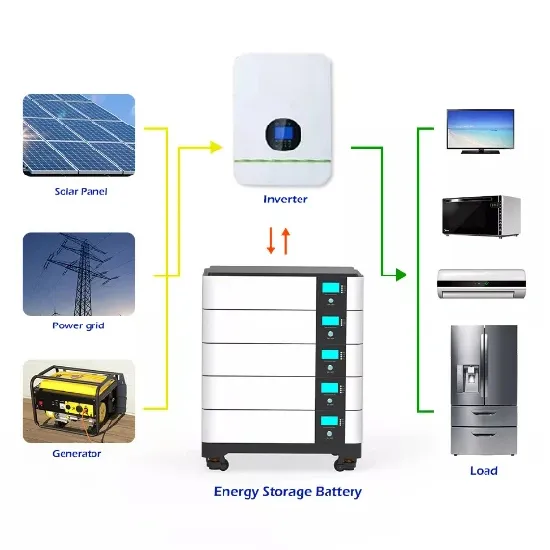

How does battery thermal management work?

Battery thermal management relies on liquid coolants capturing heat from battery cells and transferring it away through a closed-loop system. As batteries generate heat during operation, coolant flowing through cooling channels absorbs thermal energy and carries it to a heat exchanger or radiator.

What are the different types of battery thermal management systems?

Types of battery thermal management systems. Battery thermal management systems are primarily split into three types: Active Cooling is split into three types: The cell or cells are held in an enclosure, air is forced through the battery pack and cools the cells.

What is battery thermal management system?

The battery thermal management system can be divided into active thermal management system and passive thermal management system, let’s have a look at their respective working principle. Active thermal management involves using gases (including air), liquids or refrigerants to flow through all the cells in the battery to lower the temperature.

How do thermal pads work in battery thermal management systems?

Thermal pads in battery thermal management systems fill micro-gaps between cells and cooling plates for heat transfer efficiency. High-conductivity thermal pads reduce interfacial resistance, ensuring consistent heat dissipation.

What is a thermal control unit?

Thermal Control Unit: This component manages all activities in the battery thermal management system, including processing power from sensors, setting fan speeds, operating liquid pumps, and controlling heat elements. Additionally, this control system is typically integrated with the Battery Management System (BMS).

What is a battery thermal management system (PCM)?

PCM typically utilizes materials that can absorb or release heat during phase changes to regulate battery temperature. The material used in this type of battery thermal management system is generally one that can change shape from a solid to a liquid and back again.

More related information

-

Battery Cabinet Thermal Management System Company

Battery Cabinet Thermal Management System Company

-

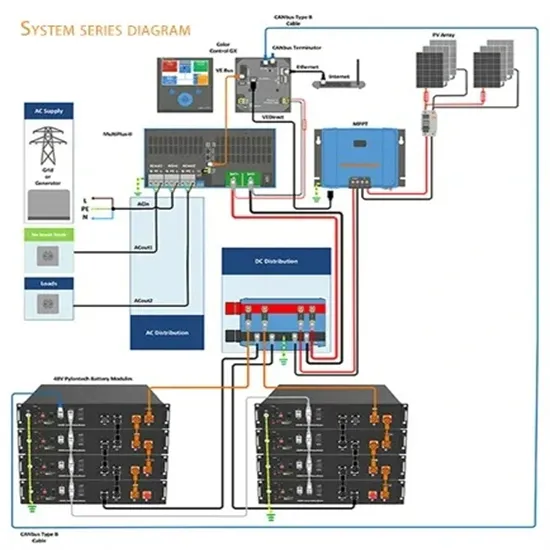

How to connect a network battery cabinet to an ESS power base station

How to connect a network battery cabinet to an ESS power base station

-

How to install a battery cabinet in a small apartment

How to install a battery cabinet in a small apartment

-

How many strings are used for a 12v outdoor battery cabinet

How many strings are used for a 12v outdoor battery cabinet

-

How to connect 16 batteries in a battery cabinet

How to connect 16 batteries in a battery cabinet

-

How to make a battery cabinet without circuit boards

How to make a battery cabinet without circuit boards

-

How much is the price of the new energy original battery cabinet

How much is the price of the new energy original battery cabinet

-

How much lead acid is in the energy storage cabinet battery

How much lead acid is in the energy storage cabinet battery

Commercial & Industrial Solar Storage Market Growth

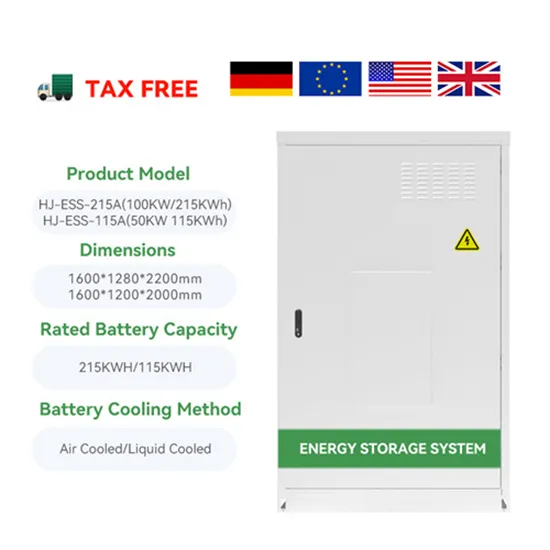

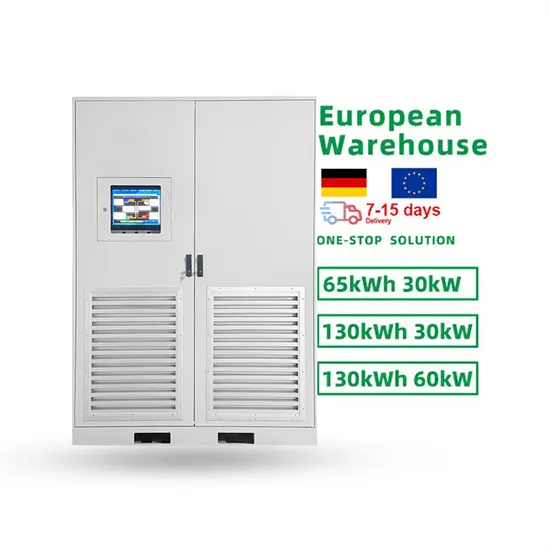

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.