Recycling of Utility-Scale Battery Storage Systems: Maximizing

Solar battery recycling involves several steps to dismantle, process, and dispose of the batteries properly. The first step is safely transporting the batteries from the

Get Price

Advancing energy storage: The future trajectory of lithium-ion battery

Lithium-ion batteries are pivotal in modern energy storage, driving advancements in consumer electronics, electric vehicles (EVs), and grid energy storage. This review explores

Get Price

Advancing sustainable battery recycling: towards a circular

About this report This is the first comprehensive synthesis of the fragmented knowledge on sustainability in electric vehicle lithium-ion battery (LIB) recycling. The report aims to build a

Get Price

Lithium battery reusing and recycling: A circular

Driven by the rapid uptake of battery electric vehicles, Li-ion power batteries are increasingly reused in stationary energy storage systems, and eventually

Get Price

Recycling of Utility-Scale Battery Storage Systems:

Solar battery recycling involves several steps to dismantle, process, and dispose of the batteries properly. The first step is safely

Get Price

It''s time to get serious about recycling lithium-ion

Because the Li-ion battery industry lacks a clear path to large-scale economical recycling, battery researchers and manufacturers have traditionally not

Get Price

Batteries for Electric Vehicles

Energy storage systems, usually batteries, are essential for all-electric vehicles, plug-in hybrid electric vehicles (PHEVs), and hybrid electric vehicles (HEVs). Types of Energy Storage

Get Price

Recycling lithium-ion batteries delivers significant environmental

Lithium-ion battery recyclers source materials from two main streams: defective scrap material from battery manufacturers, and so-called "dead" batteries, mostly collected

Get Price

Lithium-Ion Battery Critical Materials Sustainability | ACS Energy

This viewpoint addresses the growing sustainability concerns surrounding critical materials in lithium-ion batteries (LIBs) due to increasing electric vehicle demand. It highlights

Get Price

It''s time to get serious about recycling lithium-ion batteries

Because the Li-ion battery industry lacks a clear path to large-scale economical recycling, battery researchers and manufacturers have traditionally not focused on improving recyclability.

Get Price

Lithium-Ion Battery Recycling Frequently Asked Questions

Batteries can be shredded for recycling at a destination facility, either a hazardous waste recycler with no storage before recycling or a RCRA-permitted treatment, storage, and

Get Price

Battery Storage Company | Lithium Ion Battery Recycling Company

Renewance, a leading industrial battery lifecycle service solutions company, helps you manage key battery energy storage asset activities throughout the full battery lifecycle.

Get Price

From waste to value: the potential for battery recycling

While nickel-rich NMC recycling has traditionally received a lot of focus given the mature (and economically attractive) recovery of nickel and

Get Price

Energy Saver: Consumer Guide to Battery Recycling

It is equally important to handle batteries safely, because some batteries can pose health risks if mishandled at the end of their lives. Batteries that appear to be discharged can still contain

Get Price

The evolution of lithium-ion battery recycling

This Review discusses industrial and developing technologies for recycling and using recovered materials from spent lithium-ion batteries.

Get Price

Why recycling ''dead'' batteries could save billions and slash pollution

Lithium battery recycling offers a powerful solution to rising demand, with discarded batteries still holding most of their valuable materials. Compared to mining, recycling

Get Price

A Review of Lithium-Ion Battery Recycling:

This paper provides a comprehensive review of lithium-ion battery recycling, covering topics such as current recycling technologies,

Get Price

Lithium battery reusing and recycling: A circular economy insight

Driven by the rapid uptake of battery electric vehicles, Li-ion power batteries are increasingly reused in stationary energy storage systems, and eventually recycled to recover

Get Price

Guide To Recycling Battery Storage Systems | Eco

Wondering what happens to battery storage systems once they reach the end of their life? Our guide takes a look at battery storage and

Get Price

A review of lithium-ion battery recycling for enabling a circular

Recycling methods drive net-zero emissions and support the clean energy transition. With the rapid electrification of society, the looming prospect of a substantial

Get Price

Battery recycling: everything about energy storage and lithium-ion

Battery recycling is becoming increasingly important due to the rising popularity of energy storage systems. In this article, we present our concept for the recycling of lithium-ion

Get Price

Battery recycling: everything about energy storage

Battery recycling is becoming increasingly important due to the rising popularity of energy storage systems. In this article, we present our

Get Price

Recycling and Disposal of Battery-Based Grid Energy

Battery-based grid energy storage systems—particularly systems based on lithium ion batteries—are in greater use by electric utilities. As a result, better strategies and infrastructure

Get Price

Progress, Key Issues, and Future Prospects for Li‐Ion

The overuse and exploitation of fossil fuels has triggered the energy crisis and caused tremendous issues for the society. Lithium-ion batteries (LIBs), as one

Get Price

Lithium-Ion Battery Recycling Industry Report 2025

The Global Lithium-Ion Battery Recycling Market is set to grow from $7.3B in 2024 to $23.9B by 2030, at a CAGR of 21.9%. The surge in EV adoption,...

Get Price

Lithium-ion battery demand forecast for 2030 | McKinsey

Battery energy storage systems (BESS) will have a CAGR of 30 percent, and the GWh required to power these applications in 2030 will be

Get Price

Recycling lithium-ion batteries delivers significant

Lithium-ion battery recyclers source materials from two main streams: defective scrap material from battery manufacturers, and so-called

Get Price

Lithium battery reusing and recycling: A circular economy insight

Driven by the rapid uptake of battery electric vehicles, Li-ion power batteries are increasingly reused in stationary energy storage systems, and eventually recycled to recover all the valued

Get Price

Lithium-ion battery recycling report | CAS and Deloitte

With the rise in electric vehicles, renewable energy storage, and consumer electronics, recycling lithium-ion bateries has become a critical solution to address resource scarcity and

Get Price

6 FAQs about [Lithium energy storage battery recycling]

Can lithium-ion batteries be recycled?

A review of lithium-ion battery recycling: technologies, sustainability, and open issues. Batteries 10, 38 (2024). Wagner-Wenz, R. et al. Recycling routes of lithium-ion batteries: a critical review of the development status, the process performance, and life-cycle environmental impacts. MRS Energy Sustain. 10, 1–34 (2023).

How can recycling reduce end-of-life lithium-ion batteries?

The rapid increase in lithium-ion battery (LIB) production has escalated the need for efficient recycling processes to manage the expected surge in end-of-life batteries. Recycling methods such as direct recycling could decrease recycling costs by 40% and lower the environmental impact of secondary pollution.

What is a lithium-ion battery recycling cycle?

Technical, economic, environmental and social considerations throughout the lithium-ion battery (LIB) recycling cycle. The battery cycle is captured along five dimensions: raw materials, battery manufacturing, battery use, end-of-life (EOL) batteries and recycling.

How does a lithium ion battery recycler work?

Lithium-ion battery recyclers source materials from two main streams: defective scrap material from battery manufacturers, and so-called “dead” batteries, mostly collected from workplaces. The recycling process extracts lithium, nickel, cobalt, copper, manganese, and aluminum from these sources.

What is industrial recycling of lithium-ion batteries (LIBs)?

The industrial recycling of lithium-ion batteries (LIBs) is based on pyrometallurgical and hydrometallurgical methods. a, In pyrometallurgical recycling, whole LIBs or black mass are first smelted to produce metal alloys and slag, which are subsequently refined by hydrometallurgical methods to produce metal salts.

How much lithium can be recycled?

In contrast, only 28 tons of spent lithium-ion batteries (SLIBs) are needed for leaching . Recycling can recover anywhere from 0 % to 80 % of lithium from end-of-life batteries. By 2030, the secondary recycling supply is projected to contribute slightly over 6 % of the total lithium production .

More related information

-

Lithium iron phosphate energy storage battery company

Lithium iron phosphate energy storage battery company

-

Syria lithium battery energy storage

Syria lithium battery energy storage

-

Do Energy Storage Battery Cabinets Include Lithium Batteries

Do Energy Storage Battery Cabinets Include Lithium Batteries

-

Zambia imported energy storage lithium battery brand

Zambia imported energy storage lithium battery brand

-

Explosion-proof lithium battery energy storage cabinet base station

Explosion-proof lithium battery energy storage cabinet base station

-

Energy storage lithium square battery manufacturer

Energy storage lithium square battery manufacturer

-

Greek energy storage low-temperature lithium battery factory

Greek energy storage low-temperature lithium battery factory

-

Lithium Battery Energy Storage Equipment Costs

Lithium Battery Energy Storage Equipment Costs

Commercial & Industrial Solar Storage Market Growth

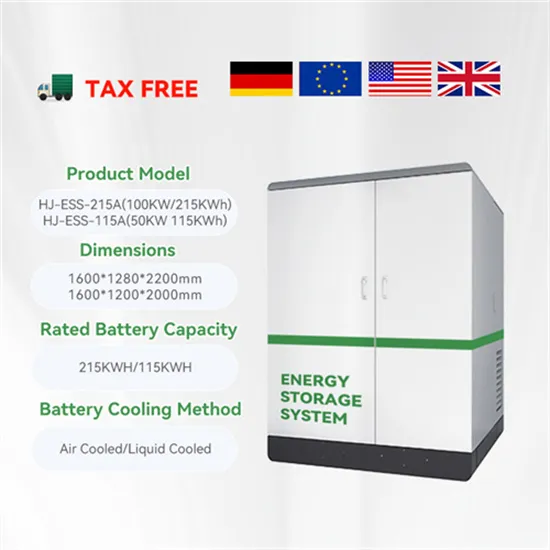

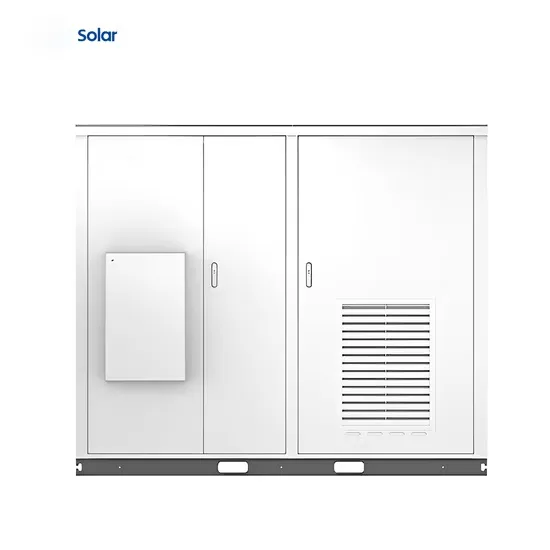

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

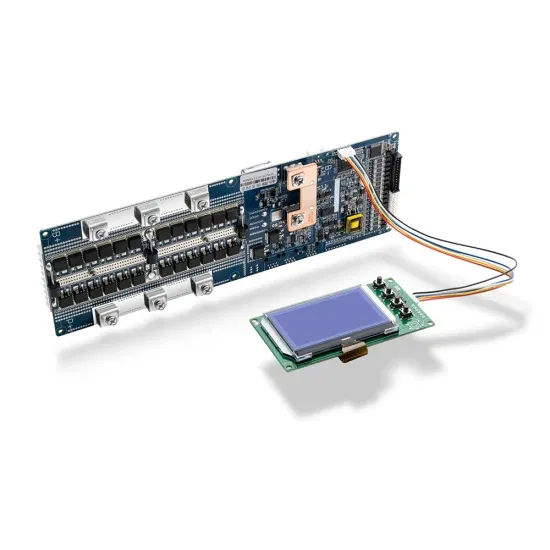

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.