BASE STATION ANTENNAS – RELIABLE WIND LOAD

METHODS OF DETERMINING THE WIND LOAD There are three recognised methods for determining the wind load of base station antennas:

Get Price

Wind Loading On Base Station Antennas White Paper

Its effects figure prominently in the design of every Andrew base station antenna. This paper focuses on how Andrew Solutions determines wind load values and Effective Drag Areas

Get Price

Blowing your way wind-powered base stations

The In-Stat research company predicts that by 2014, over 230,000 cellular base stations in developing countries will be solar-powered or wind-powered. Certainly wind power

Get Price

Top 13 Largest Wind Farms in the World by Capacity

Wind power has become one of the leading sources of clean energy around the world. Countries are building massive wind farms to reduce reliance on fossil fuels and meet

Get Price

Wind Load Test and Calculation of the Base Station Antenna

Among wind load measurement tests, the wind tunnel test simulates the environment most similar to the actual natural environment of the product and therefore is the most accurate test method.

Get Price

National Wind Watch | The Grid and Industrial Wind Power

Base load is typically provided by large coal-fired and nuclear power stations. They may take days to fire up, and their output does not vary.

Get Price

McMurdo Station

The base is powered by a mixture of generators and wind power, though it had a nuclear reactor in the 1960s. The base was first established in the mid-1950s

Get Price

How Much Concrete In The Base Of A Wind Turbine?

Geotechnical conditions and structural requirements determine the slab foundation size for giant onshore turbines. One Energy''s wind turbine foundations consist of 320 cubic

Get Price

Renewable-Energy-Powered Cellular Base-Stations in

The increasing deployment of cellular base-stations has increased the power consumption, energy cost, and associated adverse environmental

Get Price

The Role of Hybrid Energy Systems in Powering

Discover how hybrid energy systems, combining solar, wind, and battery storage, are transforming telecom base station power, reducing costs,

Get Price

How Big Is The Concrete Base Of A Wind Turbine? Key Facts

Each base, a whopping 40 feet across, utilizes up to 600 cubic yards of concrete. These massive slabs help turbines withstand wind speeds of 200 miles per hour, keeping them steady even

Get Price

RE-SHAPING WIND LOAD PERFORMANCE FOR BASE

Using a thorough understanding of the physics and aerodynamics behind wind load, we optimize the antenna design to minimize wind load. This involves using numerical methods such as

Get Price

Design and Implementation of Substitution Power Supply at Base

The availability of electric energy source in nature such as wind and solar power have not been explored and used significantly as electric power sources for human need of energy. Base

Get Price

Strategy of 5G Base Station Energy Storage Participating in the Power

The proportion of traditional frequency regulation units decreases as renewable energy increases, posing new challenges to the frequency stability of the power system. The

Get Price

Offshore wind power

A big advantage of offshore wind power compared to onshore wind power is the higher capacity factor meaning that an installation of given nameplate capacity

Get Price

Wind Turbines: the Bigger, the Better

In 2023, the average rotor diameter of newly-installed wind turbines was over 133.8 meters (~438 feet)—longer than a football field, or about as tall as the Great Pyramid of

Get Price

Base Station Antennas: Pushing the Limits of Wind Loading

By taking the time to refine measurement techniques to ensure the most accurate possible test results, we are now able to look at pushing the wind loading eficiency of base station antennas.

Get Price

Global Wind Atlas

The Global Wind Atlas is a free, web-based application developed to help policymakers, planners, and investors identify high-wind areas for wind power

Get Price

Wind Turbines: the Bigger, the Better

In 2023, the average rotor diameter of newly-installed wind turbines was over 133.8 meters (~438 feet)—longer than a football field, or

Get Price

Full article: Techno-economic assessment of photovoltaic-diesel

In order to prepare a sound framework for the adoption of a Photovoltaic system for powering telecommunication base stations in sub-Sahara Africa-specifically Nigeria, this study

Get Price

Global Wind Power Tracker

Global Wind Power Tracker The Global Wind Power Tracker (GWPT) is a worldwide dataset of utility-scale, on and offshore wind facilities.

Get Price

Turbine scale and siting considerations in wind plant layout

In this paper we show results for wind plant optimizations with three different wind turbines, with the intent to capture dif-ferences in optimal results as affected by the turbine size and cost.

Get Price

How Do Wind Power Stations Work? A Detailed Look

Wondering how do wind power stations work? A wind power station captures wind''s kinetic energy and turns it into electricity.

Get Price

How Much Concrete In The Base Of A Wind Turbine?

Geotechnical conditions and structural requirements determine the slab foundation size for giant onshore turbines. One Energy''s wind turbine

Get Price

A Sustainable Approach to Reduce Power Consumption and

Cellular base stations consume a lot of energy since it requires a 24-h continuous power supply which results in an increased operational expenditure (OPEX) and

Get Price

Mobile Wind Power Station: Portable Clean Energy

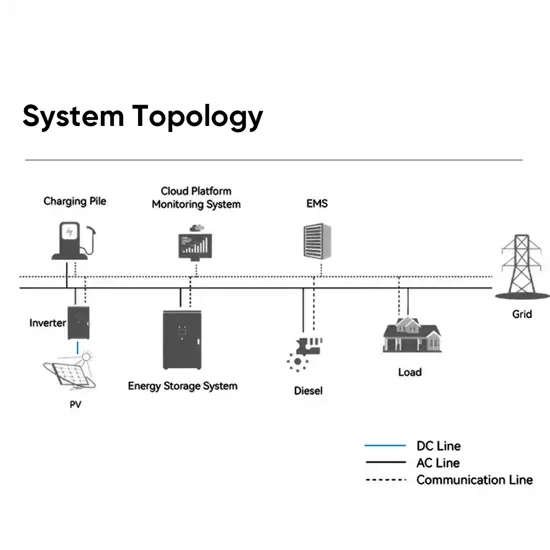

A mobile wind power station typically comprises a wind turbine, tower, controller, inverter, and energy storage equipment. The wind turbine harnesses wind energy to drive

Get Price

6 FAQs about [Base station wind power source size]

Do base station antennas increase wind load?

Base station antennas not only add load to the towers due to their mass, but also in the form of additional dynamic loading caused by the wind. Depending on the aerodynamic efficiency of the antenna, the increased wind load can be significant. Its effects figure prominently in the design of every Andrew base station antenna.

What is a wind turbine base made of?

The base of a wind turbine, typically made of concrete, is not just for show. It provides stability and support. Without it, those blades might just decide to dance a little too wildly in strong winds. Most concrete bases range from 20 to 30 feet in diameter. Some even stretch up to 50 feet, depending on the size of the turbine.

Are Andrew's base station antennas aerodynamic?

Andrew’s re-designed base station antennas are crafted to be exceptionally aerodynamic, minimizing the overall wind load imposed on a cellular tower or similar structures. Wind load is the force generated by wind on the exterior surfaces of an object.

How much concrete does a turbine base use?

Each base, a whopping 40 feet across, utilizes up to 600 cubic yards of concrete. These massive slabs help turbines withstand wind speeds of 200 miles per hour, keeping them steady even when the weather goes wild. Let’s jump to Denmark, where engineers design bases for turbines on soft soil.

Which wind direction should be considered in a base station antenna?

In aerospace and automotive industries, only unidirectional wind in the frontal direction is of concern. In the world of base station antennas, wind direction is unpredictable. Therefore, we must consider 360 degrees of wind load. Wind force on an object is complex, with drag force being the key component.

What is wind load based on?

wind load as a function of the length-to-width ratio of the antenna. For wind loads based on win on on Base Station Antenna Standards by NGMN AllianceABOUT KATHREINKathrein is a leading internation l specialist for reliable, high- quality communication technologies.We ar

More related information

-

How long is the life of a base station wind power source

How long is the life of a base station wind power source

-

Suriname communication base station wind power tower manufacturer customization

Suriname communication base station wind power tower manufacturer customization

-

How many types of base station wind power sources are there

How many types of base station wind power sources are there

-

Niue communication base station wind power products

Niue communication base station wind power products

-

Public photovoltaic communication base station wind power

Public photovoltaic communication base station wind power

-

Bolivia Communication Base Station Wind Power Construction Project

Bolivia Communication Base Station Wind Power Construction Project

-

Setting up base station combined wind power supply

Setting up base station combined wind power supply

-

Central Asia Communication Base Station Wind Power Outdoor Site

Central Asia Communication Base Station Wind Power Outdoor Site

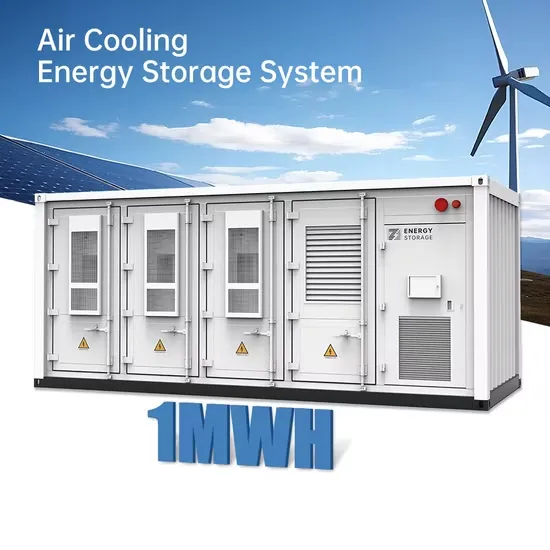

Commercial & Industrial Solar Storage Market Growth

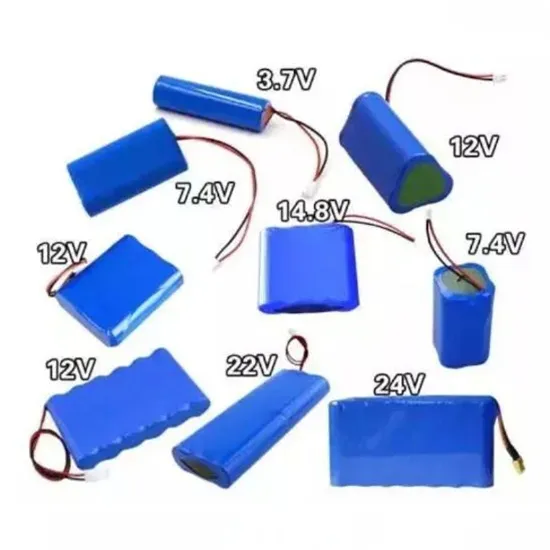

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

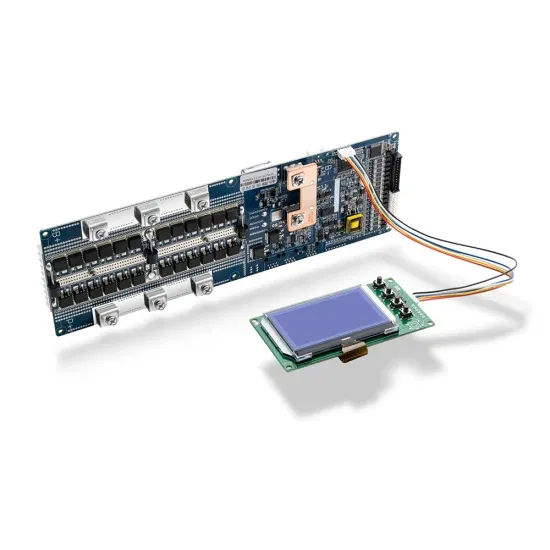

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.