Light management for photovoltaics using high-index

Strategies to increase light-trapping in solar cells can significantly improve the power-conversion efficiency of these devices. This Review

Get Price

What Is The Solar Reflectance Index? Why It Matters

Learn all about the solar reflectance index and how it plays a role in choosing shingles and other roofing materials.

Get Price

HIGH QUALITY EVA FILM FOR ENCAPSULATING SOLAR

ZXEVA film applies to crystalline silicon and thin-film solar cells encapsulation, which is a kind of thin film, with Ethylene Vinyl Acetate copolymer as the main raw material, adding variety of

Get Price

Graded Refractive Index Anti-Reflective Coatings for Solar Panels

Discover innovations in graded refractive index anti-reflective coatings to enhance solar panel efficiency and energy output.

Get Price

Improving the light transmission of silica glass using silicone as

We acquired and compared the refractive index curves, conducted structural analyses, characterizations (optical, thermal, and surface), and performance evaluations to

Get Price

ASTM D542 – Refractive Index Testing for Transparent PV Coatings

By performing refractive index testing according to ASTM D542, manufacturers can ensure their TPCs meet regulatory requirements and provide optimal performance in real-world conditions.

Get Price

Determination of the suitable refractive index of solar cells silicon

In order to determine the optimal refractive index, we developed a method which encompasses a combined analysis of the electrical and optical properties of SiN layers

Get Price

Refractive index library

Martin A. Green, ''Self-consistent optical parameters of intrinsic silicon at 300 K including temperature coefficients'', Solar Energy Materials and Solar Cells 92, pp.1305-1310, (2008)

Get Price

ASTM E335 – Refractive Index Testing of Solar Panel Glass

In this article, we will delve into the importance of refractive index testing of solar panel glass, its regulatory context, testing protocols, business benefits, and risks associated with non

Get Price

The performance and durability of Anti-reflection

Solar photovoltaics (PV) is an important source of renewable energy for a sustainable future, and the installed capacity of PV modules has

Get Price

Optical Constants of UV Transparent EVA and the Impact on the

We measure and discuss the complex refractive index of conventional ethylene vinyl acetate (EVA) and an EVA with enhanced UV-transmission based on spectroscopic

Get Price

Quantitative assessment of reflected light characteristics on solar panel

When using solar panels, the appearance of the surfaces results in a change in the optical parameters of our environment. The solar panel and the PV/T collector can change the

Get Price

Optical losses of photovoltaic cells due to aerosol deposition:

We have found that for small particles and a relatively large imaginary part of their refractive index, absorption losses dominate while for large particles and a relatively small

Get Price

The performance and durability of Anti-reflection coatings for solar

PV modules experience reflection losses of ∼4% at the front glass surface. This loss can be mitigated by the use of anti-reflection coatings, which now cover over 90% of

Get Price

Graded Index Lens as a Nontracking Solar

Stanford researchers have developed a novel, non-tracking and low cost solar concentrator - Axially Graded Index LEns: AGILE - that has potential to

Get Price

Minimizing annual reflection loss in fixed-tilt photovoltaic modules

In the push to increase efficiencies in solar panels, manufacturers have sought to minimize this reflection loss [1]. To achieve this, PV glass now typically features a thin anti

Get Price

Design of multi-layer anti-reflection coating for terrestrial solar

To date, there is no ideal anti-reflection (AR) coating available on solar glass which can effectively transmit the incident light within the visible wavelength range. However,

Get Price

The performance and durability of Anti-reflection coatings for solar

This lowers the bulk refractive index of the material since the voids have a refractive index of 1, corresponding to air. Silica (SiO2), with a refractive index of 1.47, is often used as a

Get Price

Refractive indices of layers and optical simulations of

The optical refractive indices of the front and back contact layers of a standard CIGS solar cell are determined by combining ellipsometry, reflectance, and transmittance

Get Price

Solar Reflectance Index | Daltile

Solar Reflectance Index is a measurement of the solar reflectance and thermal emissivity of materials, and is an indicator of how hot the material is likely to become when solar radiation is

Get Price

PV Systems: Low Levels of Glare and Reflectance vs.

In the below we show the reflected energy percentages of sunlight, off of some common residential and commercial surfaces. The legend and the graph lists the items from top to

Get Price

Solar Reflectance Index (SRI)

The Solar Reflectance Index (SRI) of roofing materials is gaining importance, particularly in warm and hot climates where cooling is a primary concern. The SRI value is based on a material''s

Get Price

PV Systems: Low Levels of Glare and Reflectance vs.

In the below we show the reflected energy percentages of sunlight, off of some common residential and commercial surfaces. The legend and the graph lists the items from top to

Get Price

Solar Cells & Refractive Index

The idea of using a higher refractive index material, like flint glass, on solar cells is debated, with concerns about increased reflection and the misconception that this would lower

Get Price

6 FAQs about [Solar panel refractive index]

How can we determine the optimal refractive index of silicon solar cells?

In order to determine the optimal refractive index, we developed a method which encompasses a combined analysis of the electrical and optical properties of SiN layers deposited on multicrystalline silicon solar cells.

What should the refractive index of optical materials be?

The refractive index of optical materials should ideally be constant over the desired wavelength range and this is mostly the case for these materials, although ZnO and TiO2 show an increase in refractive index towards 400 nm.

What is the ideal refractive index for a single layer AR coating?

The ideal refractive index, ni, for such a coating is given by equation (1): (1) n i = n 1 n 2 where n 1 and n 2 are the refractive indices of the existing layers. The refractive indices of air and glass are 1 and 1.5 respectively, so the ideal refractive index for a single layer AR coating between glass and air is 1.22.

Which solid material has a low refractive index?

However, no solid material has a refractive index this low. Magnesium fluoride (MgF2) is the closest viable material with a refractive index of 1.32 and has been widely used as a single-layer AR coating in research settings as a result , .

How to optimize refractive index?

Thus, for each system, the refractive index must be optimized. Usually, this optimization is performed using float zone (FZ) or high quality Czochralski (CZ) silicon wafers by measuring minority carrier lifetime (τ) or surface recombination velocity , , .

What is the difference between high and low refractive index?

The use of multiple layers of high and low refractive index creates a coating that lowers reflection across a broader wavelength range. In this context, ’high’ refers to a refractive index typically above n = 2 at 550 nm, and ’low’ is a value closer to that of glass, around 1.5.

More related information

-

10 watt solar photovoltaic panel

10 watt solar photovoltaic panel

-

How much power does a 6 watt solar panel produce

How much power does a 6 watt solar panel produce

-

How many kilowatts can a solar panel output

How many kilowatts can a solar panel output

-

Huawei s solar panel factory in Serbia

Huawei s solar panel factory in Serbia

-

How much power does a two-watt solar panel produce

How much power does a two-watt solar panel produce

-

Can solar panel sun sheds be used for photovoltaics

Can solar panel sun sheds be used for photovoltaics

-

Which solar panel photovoltaic module manufacturer is best in Haiti

Which solar panel photovoltaic module manufacturer is best in Haiti

-

Communication base station solar panel production company

Communication base station solar panel production company

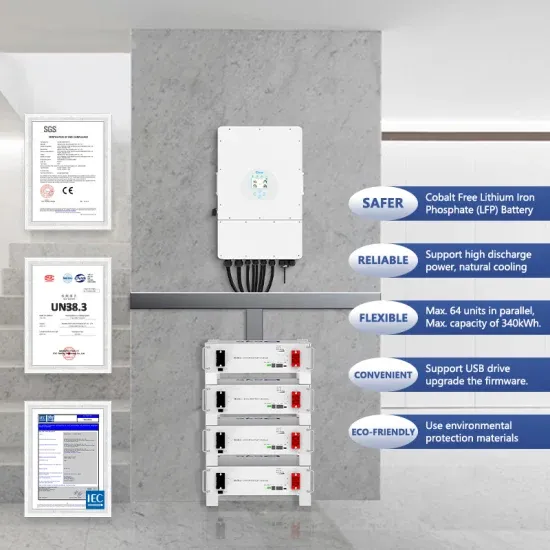

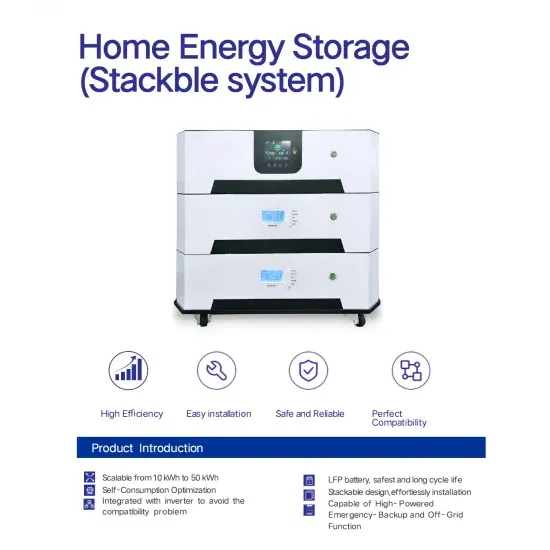

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.