From Cell Testing to Finished Product: A Complete Processing

Creating a battery pack is a complex process that requires precision, expertise, and attention to detail. From cell testing to the finished product, each step is essential in

Get Price

The Fundamentals of Battery/Module Pack Test

Battery pack and module testing is more critical than ever. Today''s engineers face new challenges including increased complexity of the tests and set-ups, long development and test

Get Price

Battery Manufacturing Process: Materials, Production

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Price

PRODUCTION PROCESS OF BATTERY MODULES AND

Attach or apply the seals (e.g. rubber seal, sprayed or bonded seals) to the edge of the housing or lid. Place the upper part of the housing or lid and connect it (e.g. by screwing) to the battery

Get Price

From Raw Materials to Finished Product: The Lithium

The battery pack manufacturing process plays an important vital role in making li-ion batteries highly efficient, reliable, environmentally friendly,

Get Price

What Is the Process of Lithium-Ion Battery Pack Assembly

Starting from individual lithium battery cells to automated modules and finally to the battery pack production line, the level of automation in the assembly process is critical for

Get Price

Quality Inspection for Battery Capacity Cycle

Nebula power Li-ion battery pack final product test system is ideal for the basic and protection performance test of high-power battery packs, such as the Li-ion battery packs of electric

Get Price

Integrated tester for finished battery pack

Integrated tester for finished battery pack Manufacturers and Factory. We accept OEM custom products all made in China.

Get Price

51.2V 48V 16S 314Ah 300Ah 280Ah Semi-Finished

51.2V/48V 16S LiFePo4 DIY Battery Kit with JK 200A BMS for Solar Energy Storage – 314Ah/300Ah/280Ah Semi-Finished Pack Customizable 51.2V/48V

Get Price

9 Steps to Know How a Battery Pack Is Made

Manufacturing a high-quality battery pack is a complex process that requires precision, expertise, and strict quality control. From selecting the right materials to final inspection and testing, each

Get Price

What Is the Process of Lithium-Ion Battery Pack

Starting from individual lithium battery cells to automated modules and finally to the battery pack production line, the level of automation in the

Get Price

PACK Process Core: Semi-Finished Product Assembly Analysis

A power battery system can be metaphorically compared to an army that needs to sustain operations for 5–10 years, with each component playing distinct roles and functions:Power

Get Price

Leading Manufacturer for Battery Cycler

Overview: Nebula power Li-ion battery pack final product test system is ideal for the basic and protection performance test of high-power battery packs, such as the Li-ion battery packs of

Get Price

Battery Manufacturer Tell You Everything About

It can be divided into the preparation of positive and negative electrode materials, battery cell forming, battery cell injection, and battery cell

Get Price

9 Steps to Know How a Battery Pack Is Made

Manufacturing a high-quality battery pack is a complex process that requires precision, expertise, and strict quality control. From selecting the right

Get Price

100V 120A Battery Pack Comprehensive Tester For

Tmax is a professional 100V 120A Battery Pack Comprehensive Tester for Performance of Finished Battery Testing,Battery Pack Comprehensive Tester

Get Price

18650 Battery Pack Tester Manufacturer, Battery Pack Testing

The 18650 battery pack tester is our second generation lithium-ion battery pack testing equipment for the finished battery analyzer.

Get Price

Battery Manufacturer Tell You Everything About Battery Packs

It can be divided into the preparation of positive and negative electrode materials, battery cell forming, battery cell injection, and battery cell finished products.

Get Price

Professional China Battery Energy Storage Testing System

Overview: Nebula power Li-ion battery pack final product test system is ideal for the basic and protection performance test of high-power battery packs, such as the Li-ion battery packs of

Get Price

From Raw Materials to Finished Product: The Lithium Batteries

The battery pack manufacturing process plays an important vital role in making li-ion batteries highly efficient, reliable, environmentally friendly, and mainly safe, for consumer

Get Price

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get Price

Lithium Battery Module PACK Manufacturing Guide

This article outlines the key points of the lithium battery module PACK manufacturing process, emphasizing the critical stages contributing to the final product''s

Get Price

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get Price

From Cell Testing to Finished Product: A Complete

Creating a battery pack is a complex process that requires precision, expertise, and attention to detail. From cell testing to the finished

Get Price

6 FAQs about [Pack battery a finished product ]

What makes a successful battery pack manufacturing process?

Effective cell selection and procurement lay the groundwork for successful battery pack manufacturing, directly impacting the quality and performance of the final product. The battery cell manufacturing process is a complex, multi-step procedure that ensures the efficiency, safety, and longevity of battery packs.

How a battery pack is made?

The assembly of the battery pack manufacturing process is done by grouping cells into series or parallel arrangements as per the need to achieve the desired voltage and capacity. For efficient and simple flow of current between cells, the cells are usually connected using busbars.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

What makes a good battery pack?

The foundation of any high-performance battery pack begins with selecting the right battery cells. This critical decision influences the overall performance, lifespan, safety, and cost of the final battery pack. Different applications require specific types of battery cells based on their unique characteristics:

What is a battery pack?

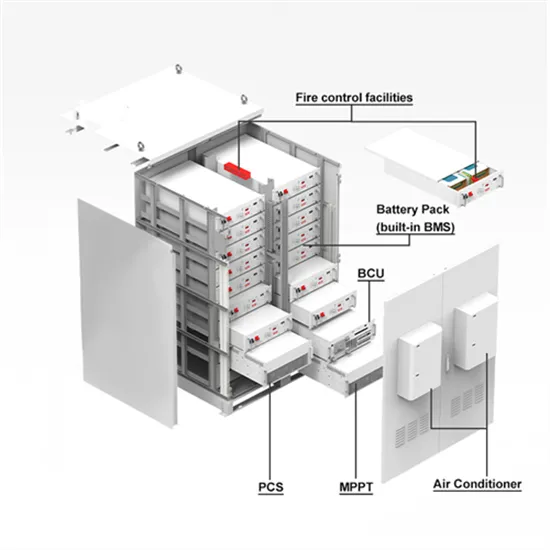

A battery pack contains any number of battery modules along with additional connectors, electronics, or packaging. The above distinction is important as battery cells are treated as individual components whereas battery modules and packs are treated as an assembly (reference Figure 3).

What is a lithium battery pack?

The Lithium battery pack may be used in the end product, such as electrical vehicles, portable devices, etc. The battery pack manufacturing process plays an important vital role in making li-ion batteries highly efficient, reliable, environmentally friendly, and mainly safe, for consumer and industrial applications.

More related information

-

Lithium battery station cabinet finished product

Lithium battery station cabinet finished product

-

Turkmenistan large-cell lithium battery pack

Turkmenistan large-cell lithium battery pack

-

Morocco pack battery

Morocco pack battery

-

6v rechargeable lithium battery pack

6v rechargeable lithium battery pack

-

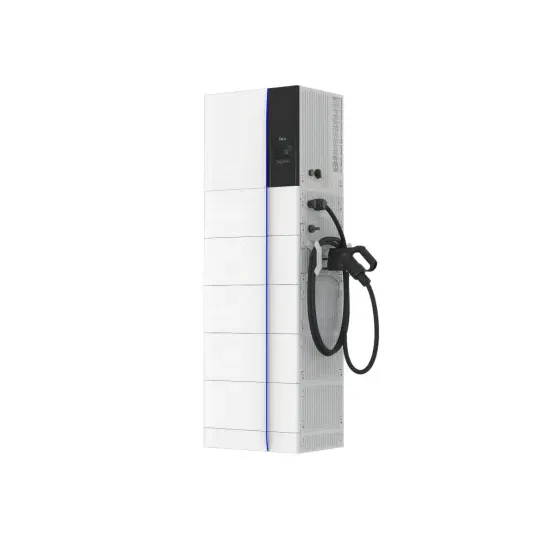

48v lithium battery pack wall mounted

48v lithium battery pack wall mounted

-

High-power lithium battery pack production

High-power lithium battery pack production

-

Energy storage lithium battery pack manufacturers

Energy storage lithium battery pack manufacturers

-

Lithium battery pack 100 kWh

Lithium battery pack 100 kWh

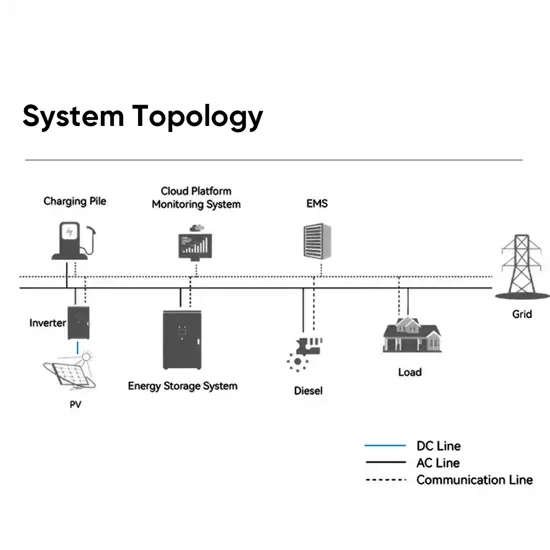

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.