Mastering These 16 Frequency Inverter Parameter Settings Will

Also known as torque compensation, this compensates for the torque drop at low speeds due to the stator winding resistance by increasing the V/f ratio in the low-frequency

Get Price

Variable Frequency Drive Working Principle

A variable frequency drive, also called frequency inverter, adjustable speed drive, the basic working principle is adjusting the electrical supply to an AC motor with a corresponding

Get Price

A Complete Guide to Inverters/Variable Frequency Drives

In this article, we will take a look at what an inverter is, where inverters are used, why we use them, and finally some of the most frequently asked questions about inverters/VFDs.

Get Price

Variable Frequency Drive Working Principle

A variable frequency drive, also called frequency inverter, adjustable speed drive, the basic working principle is adjusting the electrical supply to an AC motor

Get Price

How Variable Frequency Drive (VFD) controls Motor Speed?

In this video, we explore how a Variable Frequency Drive (VFD) Inverter operates to control an AC motor''s speed by adjusting the frequency of the voltage supplied.

Get Price

Variable-frequency drive

A variable-frequency drive (VFD, or adjustable-frequency drive, adjustable-speed drive, variable-speed drive, AC drive, micro drive, inverter drive, variable

Get Price

What is a VFD? Learn how Variable Frequency Drives

A Variable Frequency Drive (VFD), also called a frequency inverter, frequency converter, or AC drive, is an electronic device that regulates the

Get Price

Frequency inverters | Explanation, function & design

Frequency inverters are electronic devices that create an AC voltage with variable frequency from an AC voltage with fixed frequency (e.g. 50 Hz). They are

Get Price

Variable Frequency Drive (VFD): A Comprehensive Guide

A Variable Frequency Drive (VFD) – also known as a variable speed drive (VSD), adjustable frequency drive (AFD), or simply an AC inverter – is an electronic controller that adjusts the

Get Price

Introduction to Variable Frequency Drives (VFDs) and Key Benefits

Inverter: Converts DC back into AC with a variable frequency. Controller: Manages the operation of the VFD, adjusting the frequency and voltage to meet the motor''s needs.

Get Price

What is Frequency Converter? How it works?

Therefore, the frequency converter must constantly vary "peak" voltage, with respect to frequency, in order to maintain a constant effective voltage. The

Get Price

What is a VFD? Learn how Variable Frequency Drives work

A Variable Frequency Drive (VFD), also called a frequency inverter, frequency converter, or AC drive, is an electronic device that regulates the speed and performance of an

Get Price

Mastering These 16 Frequency Inverter Parameter

Also known as torque compensation, this compensates for the torque drop at low speeds due to the stator winding resistance by increasing

Get Price

WHITE PAPER UNDERSTANDING VARIABLE

COMPONENTS OF A VFD A variable frequency drive is an electronic control circuit used to control an electric motor. A VFD produces controlled pulses of voltage and current in a specific

Get Price

Understanding inverter frequency – effects and adjustments

Central to their operation is the concept of an inverter frequency, which determines the rate at which the current alternates direction. In this comprehensive guide, we delve into

Get Price

Setting up a Variable Frequency Drive

It''s a simple way of optimising the Voltage to frequency relationship for constant torque (industrial mode) or variable torque (Pump or Fan mode) applications.

Get Price

A Complete Guide to Inverters/Variable Frequency Drives

Variable voltage variable frequency supply to the motor is obtained within the Inverter Control itself using suitable control based on the principles of PWM or PSM (phase shift modulation).

Get Price

Voltage Stabilization for VFDs

Using a variable frequency drive (VFD) to control an electric motor allows the ability to adjust the voltage output to the motor for optimal efficiency.

Get Price

What Does a VFD Do?A Complete Guide to Variable

A Variable Frequency Drive (VFD),also known as an adjustable-speed drive or inverter,is a critical component in modern motor control

Get Price

Understanding Variable Frequency Drives (VFDs): Components,

What is a VFD? A Variable Frequency Drive (VFD) is an electronic device used to precisely control the speed of an electric motor by adjusting the frequency and voltage of the power it

Get Price

What is a VFD: Unlocking the Power of Variable Frequency

Variable Frequency Drives (VFDs) (also known as adjustable-frequency drive, adjustable-speed drive, variable-speed drive, AC drive, micro drive, inverter drive) are

Get Price

How Variable Frequency Drive (VFD) controls Motor Speed?

In this video, we explore how a Variable Frequency Drive (VFD) Inverter operates to control an AC motor''s speed by adjusting the frequency of the voltage supplied.

Get Price

What''s the Difference Between an Inverter and a Variable-Speed

In the context of HVAC systems, the inverter adjusts the frequency and voltage of the power to control the speed of the compressor motor. This technology is what enables the

Get Price

Voltage Control Techniques for Inverters | EEEGUIDE

Variable voltage variable frequency supply to the motor is obtained within the Inverter Control itself using suitable control based on the principles of PWM or PSM (phase shift modulation).

Get Price

How Variable Frequency Drives (VFDs) Work

Conclusion Variable Frequency Drives are a marvel of modern engineering, offering precise control over motor speed and energy consumption in a wide range of

Get Price

How Variable Frequency Drives (VFDs) Boost Energy Efficiency

What is a variable frequency drive (VFD)? A VFD regulates the frequency and voltage supplied to the motor, allowing it to operate at speeds tailored to specific load

Get Price

Variable Frequency Drives from the Inside Out

The inverter converts DC power back into controlled AC power to regulate motor speed. By adjusting frequency and voltage output, the inverter provides precise speed control, reducing

Get Price

What Does a VFD Do?A Complete Guide to Variable Frequency

A Variable Frequency Drive (VFD),also known as an adjustable-speed drive or inverter,is a critical component in modern motor control systems.But what exactly does a VFD

Get Price

Frequency Inverter

Understanding Frequency Inverters: Operation, Applications, and Benefits Frequency Inverters, also known as Variable Speed Drives (VSD) or Variable

Get Price

More related information

-

Three-phase constant voltage variable frequency inverter

Three-phase constant voltage variable frequency inverter

-

Southern Europe inverter output voltage and frequency

Southern Europe inverter output voltage and frequency

-

Does the inverter frequency regulation voltage change

Does the inverter frequency regulation voltage change

-

Medium frequency inverter output voltage

Medium frequency inverter output voltage

-

Power frequency inverter secondary primary voltage

Power frequency inverter secondary primary voltage

-

What is the voltage of a 96V household power frequency inverter

What is the voltage of a 96V household power frequency inverter

-

The inverter high frequency voltage becomes 50hz

The inverter high frequency voltage becomes 50hz

-

Variable frequency inverter 12V

Variable frequency inverter 12V

Commercial & Industrial Solar Storage Market Growth

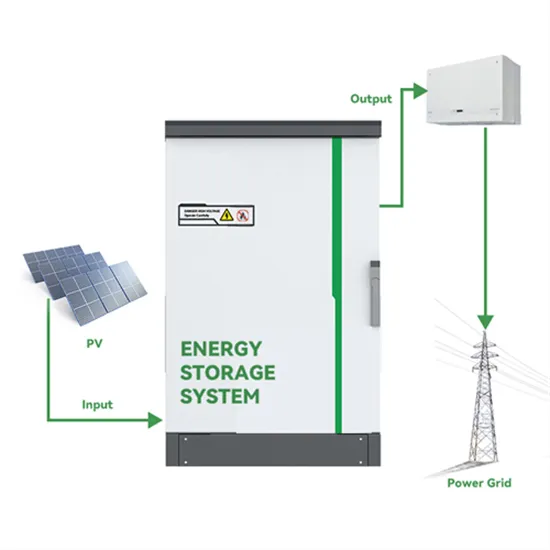

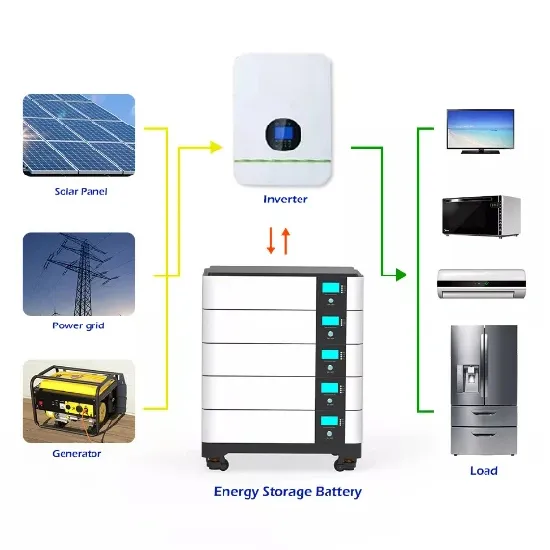

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.