Designing Industrial Battery Rooms: Fundamentals and Standards

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards.

Get Price

Comprehensive Guide to Battery Room Protection: NFPA Codes

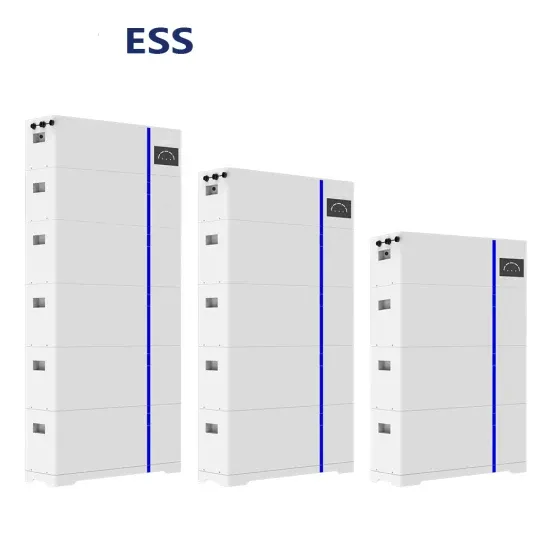

Battery rooms, especially those housing large energy storage systems (ESS), are critical components of modern infrastructure. However, they also pose significant fire risks due

Get Price

480.9 Battery Locations.

Section 480.9 (E) requires any personnel doors intended for entrance to, and egress from a battery room, to open in the direction of egress and be

Get Price

The difference between weak current engineering and weak current

The weak current project is a hidden project, and it is also the connecting nerve of the smart home. Weak current engineering construction Compared with strong electricity, we

Get Price

How to Build a Battery Room for Lithium-ion, Traction,

No battery room is complete without a full suite of safety equipment. Fire protection is paramount—install Class C fire extinguishers

Get Price

480.9 Battery Locations.

Section 480.9 (E) requires any personnel doors intended for entrance to, and egress from a battery room, to open in the direction of egress and be equipped with listed panic hardware.

Get Price

Battery cabinet installation in weak current room

A battery room should be located in a way that provides access for lifting equipment to be used during initial installation and future maintenance operations and as free from vibration as

Get Price

BATTERY AND SUBSYSTEM ELEMENTS OF A HVDC

With a grounded battery installed on a grounded stand, or inside a grounded cabinet as might be the case of a VRLA battery, it is appropriate to reduce the battery voltage with respect to

Get Price

Where can the battery system be installed? What are the

Gravel can be used as the base beneath each battery to mitigate water pooling and ensure stability. If you would like a different base, such as a concrete pad or concrete pavers, you

Get Price

Specifications and models of cabinets in weak current room

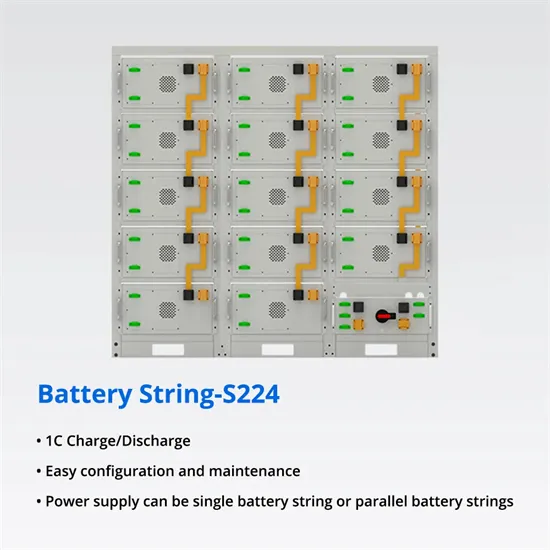

energy storage cabinet container weak current installation requirements SPECIFICATIONS-Air Cooling Energy Storage System The 115kWh air cooling energy storage system cabinet

Get Price

Substation DC Auxiliary Supply – Battery And Charger

In a typical installation, especially with batteries of considerable size, the batteries are installed in a separate battery room. The ventilation of

Get Price

Where can the battery system be installed? What are the

Each battery occupies a 3ft x 3ft area and is just over 36 inches tall, which is crucial for planning installation space appropriately. The Base installation team tailors configurations to specific

Get Price

Battery Charging Room Regulations and Safety Information | BHS

Battery Room Regulations and OSHA Battery Charging Requirements To assure safe operating conditions in and around the lift truck battery room, it is important to comply with all relevant

Get Price

Installation of battery cabinet in weak current room

Install the battery cabinet using adjustable leveling legs to ensure the cabinet is level and stable. Ensure the surface supporting the battery cabinet is rated to withstand the weight of the

Get Price

Electrical Design | The location size and layout of the strong and weak

When there is no integrated wiring cabinet, the wall cabinet type weak current room can be used. When there are many systems, the area of the weak current room should

Get Price

Cooling for Mobile Base Stations and Cell Towers

BackgroundUnattended base stations require an intelligent cooling system because of the strain they are exposed to. The sensitive telecom equipment is

Get Price

Battery Room requirements | Eng-Tips

If you do not need to use a separate room for the battery-pack, consider placing them in a room where the H2 concentration can never reach dangerous levels (circulated air,

Get Price

DC battery cabinet grounding requirements and standards

Direct-current ground-fault detection. Not all battery systems have DC ground-fault detection but many do. The ground-fault detection used must be based on the grounding methodology being

Get Price

Battery Cabinets vs. Battery Racks

Smaller UPS systems (e.g, up to 250 kVA) are commonly installed directly in the computer room along with their respective battery cabinets. The

Get Price

Specifications and requirements for battery cabinets in weak

This article describes best practices for designing battery rooms including practical battery stand systems and accessible cabinet enclosures .

Get Price

Guidelines for storage & usAGE of lead acid batteries

2 Lead-Acid Batteries Lead-acid batteries are the most widely used electrical energy storage, primarily for uninterrupted power supply (UPS) equipment and emergency power system

Get Price

Electrical Design | The location size and layout of the strong and

When there is no integrated wiring cabinet, the wall cabinet type weak current room can be used. When there are many systems, the area of the weak current room should

Get Price

More related information

-

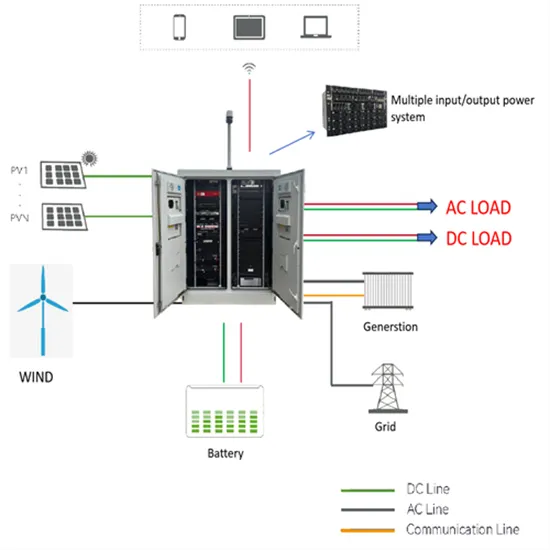

Install ESS power base station in the computer room battery cabinet

Install ESS power base station in the computer room battery cabinet

-

How to use weak current backup battery cabinet with ESS power base station

How to use weak current backup battery cabinet with ESS power base station

-

Lithium battery station cabinet fire protection system ESS power base station

Lithium battery station cabinet fire protection system ESS power base station

-

New power battery cabinet ESS power base station

New power battery cabinet ESS power base station

-

Qatar Outdoor Communication Battery Cabinet Base Station

Qatar Outdoor Communication Battery Cabinet Base Station

-

Battery cabinet dedicated base station and price

Battery cabinet dedicated base station and price

-

Outdoor battery cabinet foundation production ESS power base station

Outdoor battery cabinet foundation production ESS power base station

-

Battery cabinet protection cabinet base station and price

Battery cabinet protection cabinet base station and price

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.