How Hot Do Shipping Containers Get? | Eurolog

Explore the temperature risks in freight shipping and find out how thermal solutions can help preserve your cargo in fluctuating climates.

Get Price

Container Energy Storage System: All You Need to

Among the various #energystorage options available, container energy storage systems catch people''s attention due to their versatility,

Get Price

Life cycle cost assessment for thermal insulation of above-ground

The results of the study show that the optimum insulation thickness and energy savings rise as the water storage temperature and the diameter of the container increase.

Get Price

How many degrees can an energy storage container

Advanced storage systems like thermal energy storage can operate effectively at even more variable temperatures, enhancing

Get Price

The Monitoring and Management of an Operating Environment to

In this study, temperature and humidity monitoring and management issues were addressed for a container-type ESS by building sensor-based monitoring and control systems. Furthermore, a

Get Price

How many degrees can an energy storage container store?

Advanced storage systems like thermal energy storage can operate effectively at even more variable temperatures, enhancing performance and longevity. Energy storage

Get Price

The Monitoring and Management of an Operating

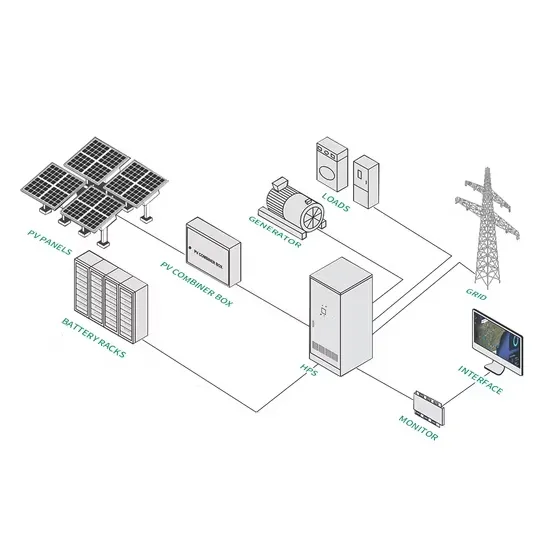

The implementation of an energy storage system (ESS) as a container-type package is common due to its ease of installation,

Get Price

How Hot Do Shipping Containers Get?

Regardless of how the temperature is regulated in a storage container, all items inside should remain safe. When the shipping container is insulated, it helps to

Get Price

Research and application of containerized energy

It discusses various aspects such as energy storage thermal management system equipment, control strategy, design calculation, and container

Get Price

Research and application of containerized energy storage thermal

Thermal runaway of battery packs is the biggest cause of fires. Therefore, the study of thermal runaway of energy storage systems is becoming a hot spot in energy storage-related research.

Get Price

How Hot Do Shipping Containers Get? | Eurolog

Explore the temperature risks in freight shipping and find out how thermal solutions can help preserve your cargo in fluctuating climates.

Get Price

Proceedings of

In this paper, the temperature mathematical model and compressor model are established to study the effect of different charge/discharge rates on air conditioning energy consumption.

Get Price

Proceedings of

Therefore, this paper studies the indoor temperature and the energy consumption of the air conditioning system of the energy storage container in one day under different

Get Price

Cold water container energy storage system

PCM packed in the storage system has a constant melting temperature equal to 5.5°C. 3. Experimental results During the experiments phase, the cold storage system had a capacity of

Get Price

Simulation analysis and optimization of containerized energy

This study analyses the thermal performance and optimizes the thermal management system of a 1540 kWh containerized energy storage battery system using CFD

Get Price

Explosion-venting overpressure structures and hazards of lithium

To comprehensively understand the risk of thermal runaway explosions in lithium-ion battery energy storage system (ESS) containers, a three-dimensional explosion-venting

Get Price

Do Storage Containers Get Hot? Unveiling the Truth Behind Container

When you''re considering storage solutions, it''s essential to ask the right questions. One key question we often hear is, " Do storage containers get hot? " The short answer is -

Get Price

Integrated cooling system with multiple operating modes for temperature

The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Get Price

Containerized energy storage system | VREMT

Containerized energy storage is an Advanced, safe, and flexible energy solution featuring modular design, smart fire protection, efficient thermal management,

Get Price

Blogs, News, Events

As the demand for energy storage systems continues to rise, investing in robust temperature control mechanisms becomes an indispensable requirement for a sustainable and

Get Price

The Monitoring and Management of an Operating Environment to

The implementation of an energy storage system (ESS) as a container-type package is common due to its ease of installation, management, and safety. The control of the

Get Price

Thermal simulation of the effect of solar radiation on

Setting the temperature of the cooling performance constant at 0°C, the fluctuations in energy consumption and temperature changes in each

Get Price

Energy Storage Containers: Reshaping The Future Of Energy Storage

Energy Storage Container Analysis of the internal structure of energy storage containers Battery cells: the foundation of energy storage The battery cell is the core of the

Get Price

Container Energy Storage System: All You Need to

Energy storage has become increasingly important in today''s world, particularly with the rise of renewable energy sources. Among the

Get Price

Integrated cooling system with multiple operating modes for

The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Get Price

Do Storage Containers Get Hot? Unveiling the Truth

When you''re considering storage solutions, it''s essential to ask the right questions. One key question we often hear is, " Do storage containers

Get Price

Simulation analysis and optimization of containerized energy storage

This study analyses the thermal performance and optimizes the thermal management system of a 1540 kWh containerized energy storage battery system using CFD

Get Price

Research and application of containerized energy

Thermal runaway of battery packs is the biggest cause of fires. Therefore, the study of thermal runaway of energy storage systems is

Get Price

Optimal configuration of cooperative stationary and mobile energy

The battery energy storage system (BESS) composed of stationary energy storage system (SESS) and shared mobile energy storage system (MESS) can be utilized to meet the

Get Price

6 FAQs about [Container Energy Storage Temperature Rise]

How much energy does a container storage temperature control system use?

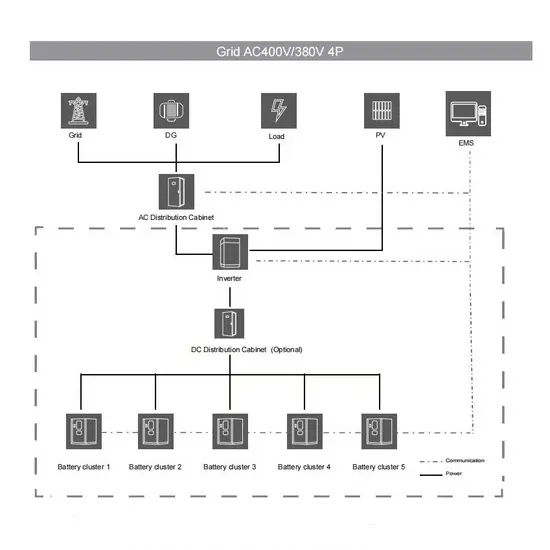

The average daily energy consumption of the conventional air conditioning is 20.8 % in battery charging and discharging mode and 58.4 % in standby mode. The proposed container energy storage temperature control system has an average daily energy consumption of 30.1 % in battery charging and discharging mode and 39.8 % in standby mode. Fig. 10.

How much power does a containerized energy storage system use?

In Shanghai, the ACCOP of conventional air conditioning is 3.7 and the average hourly power consumption in charge/discharge mode is 16.2 kW, while the ACCOP of the proposed containerized energy storage temperature control system is 4.1 and the average hourly power consumption in charge/discharge mode is 14.6 kW.

What is a container energy storage system?

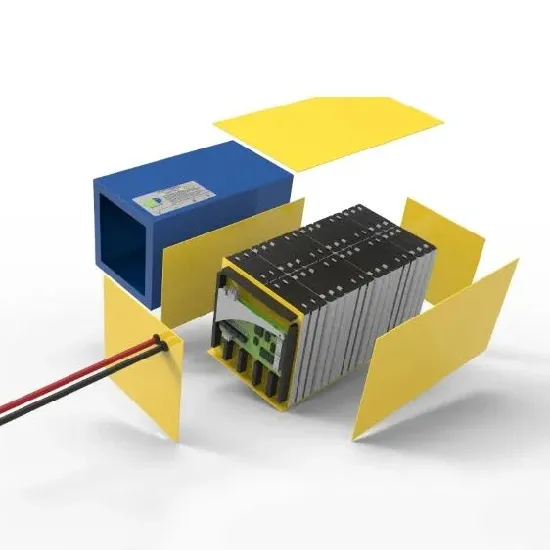

Containerized energy storage systems play an important role in the transmission, distribution and utilization of energy such as thermal, wind and solar power [3, 4]. Lithium batteries are widely used in container energy storage systems because of their high energy density, long service life and large output power [5, 6].

How to choose a compressor for a container energy storage battery?

In view of the temperature control requirements for charging/discharging of container energy storage batteries, the selection of the compressor is based on the rated operating condition of the system at 45 °C outdoor temperature and 18 °C water inlet temperature to achieve 60 kW cooling capacity.

What is a containerized energy storage battery system?

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

What is the COP of a container energy storage temperature control system?

It is found that the COP of the proposed temperature control system reaches 3.3. With the decrease of outdoor temperature, the COP of the proposed container energy storage temperature control system gradually increases, and the COP difference with conventional air conditioning gradually increases.

More related information

-

Container energy storage battery temperature standard

Container energy storage battery temperature standard

-

Container Energy Storage Battery Temperature Control

Container Energy Storage Battery Temperature Control

-

User-side energy storage container

User-side energy storage container

-

Solar integrated energy storage cabinet container installation

Solar integrated energy storage cabinet container installation

-

Guinea-Bissau Energy Photovoltaic Energy Storage Container Base Station Equipment

Guinea-Bissau Energy Photovoltaic Energy Storage Container Base Station Equipment

-

Philippine Energy Storage Container Manufacturing Company

Philippine Energy Storage Container Manufacturing Company

-

Energy storage container earthquake resistance standard price

Energy storage container earthquake resistance standard price

-

South Africa Western Energy Storage Container Company

South Africa Western Energy Storage Container Company

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.