Lithium Battery Series & Parallel Operation | Fact Sheets

Battery packs are designed by connecting multiple cells in series; each cell adds its voltage to the battery''s terminal voltage. Figure 1 below shows a typical EarthX 13.2V LiFePO4 starter

Get Price

Connecting batteries in parallel – BatteryGuy Knowledge Base

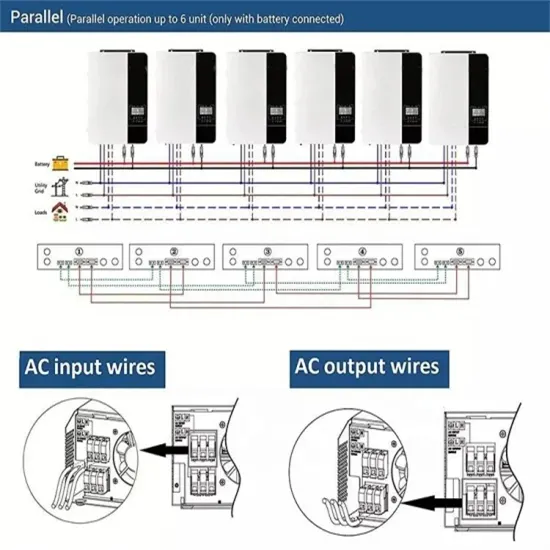

There are two ways to wire batteries together, parallel and series. The illustration below show how these wiring variations can produce different voltage and amp hour outputs.

Get Price

How to Connect Lithium Batteries in Series and Parallel?

For example, connecting four 3.7V 100mAh lithium cells in a series-parallel setup (two sets of series connections linked in parallel) will give you

Get Price

BU-302: Series and Parallel Battery Configurations

Most battery chemistries lend themselves to series and parallel connection. It is important to use the same battery type with equal voltage and capacity (Ah) and never to mix different makes

Get Price

How to Connect Lithium Batteries in Series and Parallel?

In this article, we''ll explore the basics and provide detailed, step-by-step instructions on how to connect lithium batteries in series, parallel, and series-parallel configurations.

Get Price

Analysis of lithium battery in series and parallel connections

In the development of modern technology, lithium batteries have become the primary power source for various electronic devices and electric motorcycles due to their high energy density

Get Price

Connect Batteries in Series and Parallel: What''s the

Connecting batteries can be simple once you know the basics. In series, voltage adds up while capacity stays the same—like two 12-volt, 100

Get Price

Lithium battery pack series and parallel connection diagram

Lithium Battery Instructional Wiring Diagram . Lithium Battery Wiring Instructions. All battery interconnects, busbar and device connections to resist vibration by using nylon insert lock

Get Price

How to Balance Lithium Batteries in Parallel

Balancing lithium batteries in parallel involves measuring each battery''s voltage before connection, ensuring they''re within an acceptable

Get Price

Lithium Series, Parallel and Series and Parallel Connections

Connecting multiple lithium batteries into a string of batteries allows us to build a battery bank with the potential to operate at an increased voltage, or with increased capacity and runtime, or both.

Get Price

Batteries in Series vs Parallel: Which is Better?

Connecting batteries in series or parallel could be the solution. But when you''re trying to decide to connect your batteries in series vs. parallel, which is better?

Get Price

Battery pack calculator : Capacity, C-rating, ampere, charge and

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Get Price

A visual guide to wiring a battery pack

Parallel and series connections: Depending on your power requirements, you may need to connect multiple cells in either parallel or series configurations.

Get Price

Battery configurations (series and parallel) and their

Sometimes, battery packs are used in both configurations together to get the desired voltage and high capacity. This configuration is found in the

Get Price

Connect Batteries in Series and Parallel: What''s the Best Way for

Are you frustrated trying to figure out how to boost your battery system''s power? I get it—choosing between series and parallel can feel overwhelming, especially when

Get Price

Can You Link Battery Packs? Understanding Series Vs. Parallel

When deciding between series and parallel connections for battery packs, consider factors like voltage, capacity, and application requirements. Each connection type has distinct

Get Price

Batteries in Series vs Parallel: Which is Better?

Connecting batteries in series or parallel could be the solution. But when you''re trying to decide to connect your batteries in series vs. parallel, which is better? Both methods increase total

Get Price

How to Connect Lithium Batteries in Series and Parallel?

A series-parallel connection combines both configurations to increase both voltage and capacity. For example, connecting four 3.7V 100mAh lithium cells in a series-parallel

Get Price

How to Connect Lithium Batteries in Series and Parallel?

In this article, we''ll explore the basics and provide detailed, step-by-step instructions on how to connect lithium batteries in series, parallel, and

Get Price

Science Behind Lithium-ion Batteries in Series vs

In a series connection, the voltage increases while capacity remains the same, whereas a parallel connection increases capacity without

Get Price

Connect Batteries in Series and Parallel: What''s the Best Way for

Connecting batteries can be simple once you know the basics. In series, voltage adds up while capacity stays the same—like two 12-volt, 100 AH batteries making 24 volts,

Get Price

BU-302: Series and Parallel Battery Configurations

Most battery chemistries lend themselves to series and parallel connection. It is important to use the same battery type with equal voltage and capacity (Ah)

Get Price

Ultimate Guide of LiFePO4 Lithium Batteries in Series & Parallel

Connecting lithium-ion batteries in parallel or in series is not as straightforward as a simple series-parallel connection of circuits. To ensure the safety of both the batteries and the individual

Get Price

Science Behind Lithium-ion Batteries in Series vs Parallel

In a series connection, the voltage increases while capacity remains the same, whereas a parallel connection increases capacity without changing voltage. This guide will

Get Price

Parallel then Series or Series then Parallel

Parallel then Series This is the approach used in most passenger car electric vehicles and smaller battery pack designs.

Get Price

Is it better to connect lithium batteries in series or parallel?

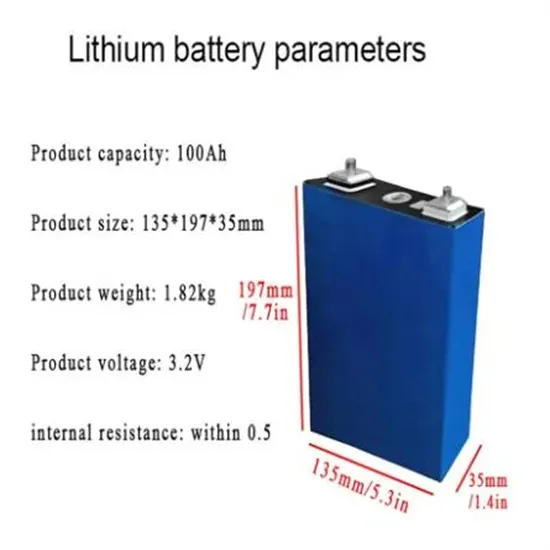

Series connections stack voltage, while parallel connections add capacity. For example, three 3.2V 100Ah LiFePO4 cells in series create a 9.6V 100Ah pack. The same cells

Get Price

Battery Packs In Series Or Parallel: Key Differences And Wiring

When choosing between series and parallel configurations for battery packs, consider voltage requirements, current capacity, space considerations, and applications.

Get Price

Lithium Battery Series & Parallel Operation | Fact Sheets

By Reg Nicoson Basics Battery packs are designed by connecting multiple cells in series; each cell adds its voltage to the battery''s terminal voltage. Figure 1 below shows a typical EarthX

Get Price

Series and Parallel, which is the first when assembling lithium battery

Series and Parallel, which is the first when assembling lithium battery packs? In the design of the battery modules, whether to connect them in series first and then in parallel

Get Price

More related information

-

Lithium battery packs used in series and parallel

Lithium battery packs used in series and parallel

-

2 parallel to 5 series 21v lithium battery pack

2 parallel to 5 series 21v lithium battery pack

-

Charging parallel lithium battery packs

Charging parallel lithium battery packs

-

Two lithium battery packs connected in parallel

Two lithium battery packs connected in parallel

-

Two identical lithium iron phosphate battery packs connected in parallel

Two identical lithium iron phosphate battery packs connected in parallel

-

Lithium battery pack first connected in series then in parallel

Lithium battery pack first connected in series then in parallel

-

Multiple energy storage battery packs can be used in parallel

Multiple energy storage battery packs can be used in parallel

-

How many 60v lithium battery packs are needed in Pakistan

How many 60v lithium battery packs are needed in Pakistan

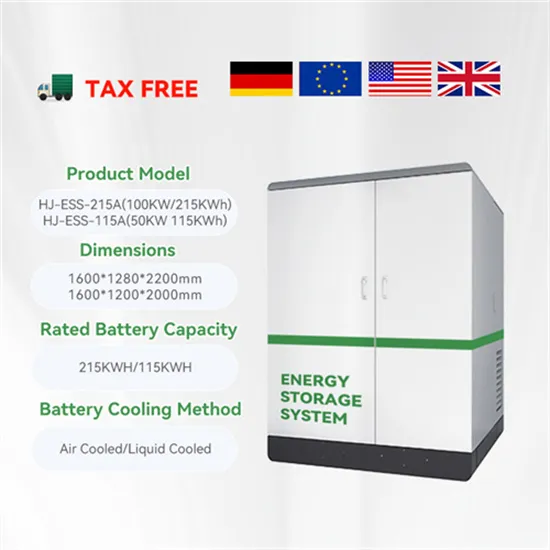

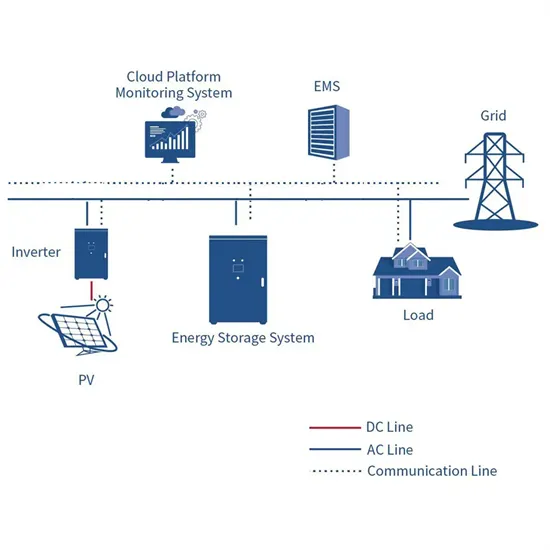

Commercial & Industrial Solar Storage Market Growth

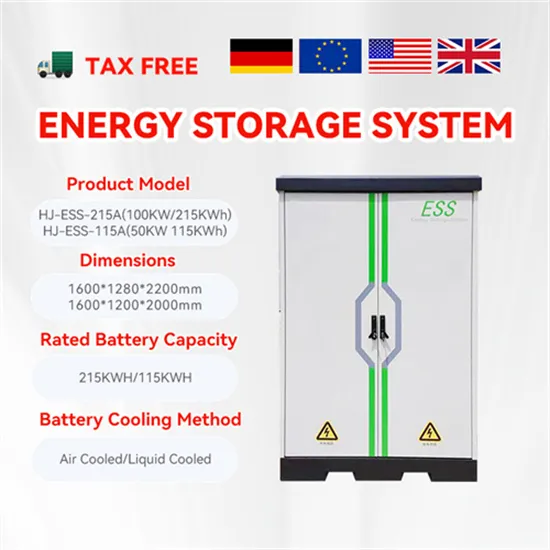

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.