Substation Communications Design -Legacy to IEC 61850

"These reference topologies were chosen based on common practice in substation automation systems ranging from small distribution systems to large multi-voltage level substations.

Get Price

Five steps to substation physical security and resiliency

Five steps to substation resiliency To help customers reach their substation security and resiliency goals, ABB has launched the Substation Physical Security and Resiliency Initiative, which

Get Price

Substation Design Guidelines

Selection of substation equipment: For switchgear - transformers, ratings of circuit breakers, switch disconnecters (Load-break switches), isolators

Get Price

Developing near overhead lines or substations | EMFs

When building or developing near an electricity substation or overhead line, you should consider safety clearance distances and compliance with relevant

Get Price

Fundamentals of Modern Electrical Substations

Part 1 of this course series is concentrated on demonstrating how modern power systems are arranged to accomplish all these goals; what place electrical substations have in the overall

Get Price

Centralized Substation Protection and Control

For example, the remote station located at a substation used to be a dedicated device manufactured by a SCADA vendor communicating over slow serial communication channels

Get Price

ES352 Design of Distribution Substations and Transforming

The requirements stated in this document relate to 11 or 6.6kV to lower voltage distribution substations and transforming points for both single customer and general network connections.

Get Price

Applying National Electrical Substations

Abstract: A discussion of the National Electrical Code (NEC) and National Electrical Safety Code (NESC) design considerations as applied to utility substations, including working clearances,

Get Price

Developing near overhead lines or substations | EMFs

When building or developing near an electricity substation or overhead line, you should consider safety clearance distances and compliance with relevant exposure limits for electric and

Get Price

Communication in substation automation systems

Simple and cost effective substation architecture: In IEC 61850 based modern substations, costly and complex network of multiple copper cables, both at the station and bay level, are replaced

Get Price

Substation

A substation is a part of an electrical generation, transmission, and distribution system. Substations transform voltage from high to low, or the reverse, or

Get Price

General Guidelines for 765/400/220/132 KV Sub-Station

3 days ago· General Guidelines for 765/400/220/132 KV Sub-Station & Switchyard of Thermal/Hydro Power Projects

Get Price

Design Guide for Rural Substations

PURPOSE: This bulletin provides a basic design guide and a reference tool for designing rural substations. GENERAL: This Bulletin has been revised to bring the publication up to date with

Get Price

Communications Equipment Used in Substations

Explore essential communication equipment for substations, including RTUs, PLCs, fiber optic and wireless solutions. Learn about key

Get Price

A Guide to NERC CIP Standards for Substation Resiliency | T&D

Although NERC CIP-014 applies to critical infrastructure, it has great value as a foundation for building resiliency plans for all substations.

Get Price

eCFR :: 29 CFR 1926.966 -

American National Standard National Electrical Safety Code, ANSI/IEEE C2-2012 contains guidelines for the dimensions of access and working space about electric equipment in

Get Price

Electric Power Generation, Transmission, and Distribution eTool

The "269" standard''s general requirements for T&D systems apply to substations; additional requirements specifically for substations are listed in 1910.269 (u) and include: Sufficient

Get Price

Business Documentation (DBD)

In regions where tidal considerations are necessary then the substation building should, where practicable, be built above the high water mark. Where water within the substation building is

Get Price

6 Simple Rules to Ensure Substation Safety

"These reference topologies were chosen based on common practice in substation automation systems ranging from small distribution systems to large multi-voltage level substations.

Get Price

Documentation and Reference Design Guide for Major

An overview of the environmental, civil, architectural, electrical primary, electrical secondary, control, protection, communications and SCADA work to be completed in the substation and

Get Price

GENERAL SPECIFICATION FOR CONTESTABLY BUILT

The products and systems to be supplied and installed under this Contract shall conform to the requirements of the specification, to the best accepted international practice for substations of

Get Price

Substation Primary Design Standard

The substation design responsibilities are broadly divided into primary and secondary systems. The primary systems are the high voltage, civil and structural and building elements.

Get Price

6 FAQs about [Requirements for substations next to communication base stations]

What are the requirements for a substation?

Substations. Application. This section provides additional requirements for substations and for work performed in them. Access and working space. The employer shall provide and maintain sufficient access and working space about electric equipment to permit ready and safe operation and maintenance of such equipment by employees.

What are substation safety standards?

The main mission of all these regulations is safeguarding of personnel from hazards arising from the installation, maintenance or operation of substation equipment. Safety standards contain requirements for: All these measures are based on common sense and the goal to provide a safe environment for substation personnel.

What is the best guide for safety in substation grounding?

For reference material, IEEE Std. 80, “Guide for Safety in Substation Grounding,” is generally recognized as one of the most authoritative guides available. It is recommended for any person concerned with the design of substation grounding systems.

What should be included in the design of a substation?

Buildup could occur that would compromise electrical insulation or interfere with cooling. Appropriate prevention measures should be included in the design of a substation expected to be exposed to such contamination. Substations interface with roadways, area drainage, communications systems, and electric power lines.

What are the IEEE guidelines for a substation?

IEEE Std. 980, “IEEE Guide for Containment and Control of Oil Spills in Substations.” IEEE Std. 1119, “IEEE Guide for Fence Safety Clearances.” IEEE Std. 1127, “IEEE Guide for the Design, Construction, and Operation of Safe and Reliable Substations for Community Acceptance and Environmental Compatibility.”

Which substations should have provisions for installation of mobile equipment?

Substations for which mobile equipment has been designated should have provisions for installation of the equipment. The provisions can simply be terminals on permanent substation equipment or buses for connecting the mobile equipment.

More related information

-

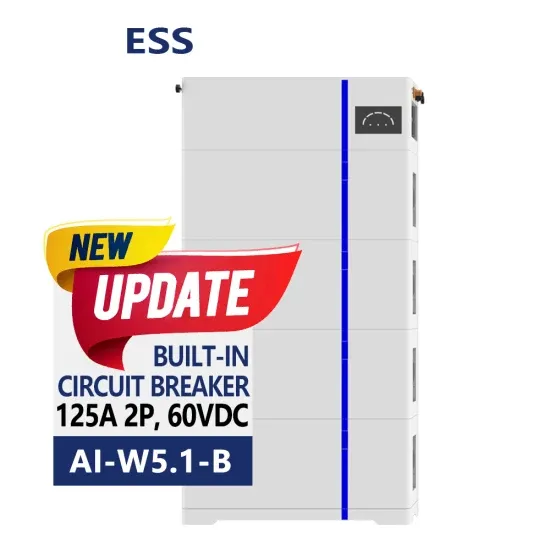

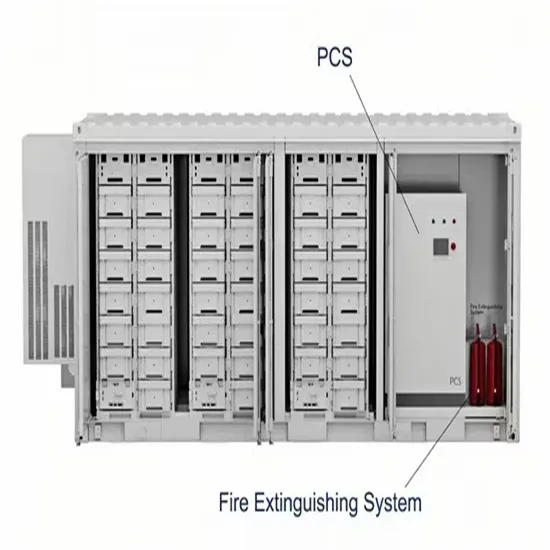

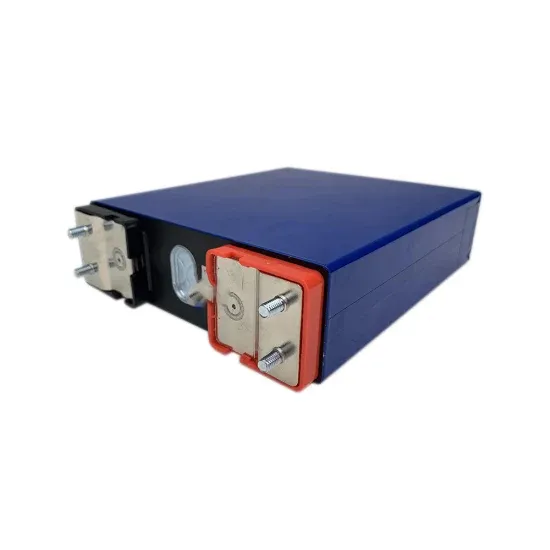

Design requirements for energy storage cabinets in communication base stations

Design requirements for energy storage cabinets in communication base stations

-

Battery configuration requirements for communication base stations

Battery configuration requirements for communication base stations

-

Mozambique recruits battery energy storage for communication base stations

Mozambique recruits battery energy storage for communication base stations

-

Innovation in wind power technology for communication base stations

Innovation in wind power technology for communication base stations

-

Inverters are required for communication base stations in the Republic of South Africa

Inverters are required for communication base stations in the Republic of South Africa

-

Communication between IoT devices and base stations

Communication between IoT devices and base stations

-

Can wind power from communication base stations predict earthquakes

Can wind power from communication base stations predict earthquakes

-

Where are the communication base stations in Kuwait

Where are the communication base stations in Kuwait

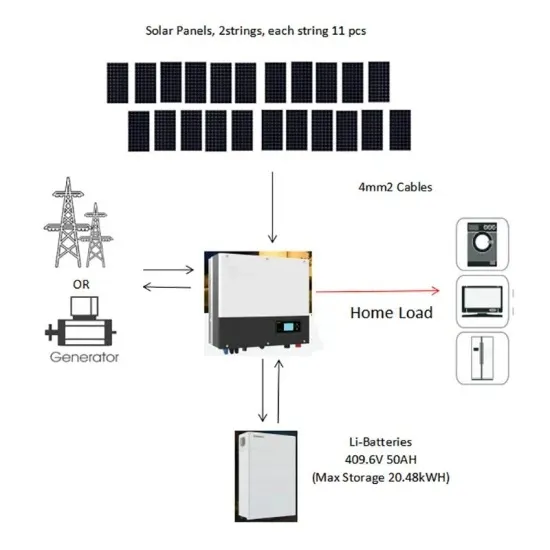

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.