FEMA P-1019 Emergency Power Systems for Critical

This document examines the vulnerability of electrical power systems to natural hazards, describes what equipment in critical facilities should be supplied by emergency

Get Price

Job Safety Analysis and Activity Hazard Analysis for

When working with electrical power as part of our job, it is critical to use a job safety analysis or activity hazard analysis for electrical work to ensure proper

Get Price

Power Plant Construction Projects Risk Assessment: A Proposed

With the proposed method, which has been tested in real industrial facilities, it has been possible to increase the safety of the system and reduce the likelihood of incidents and

Get Price

Final+ +telecommunications | PDF | Base Station

A typical cellular telecommunication network consists of a number of base stations. Each base station is designed to serve a geographical area of network coverage and may be

Get Price

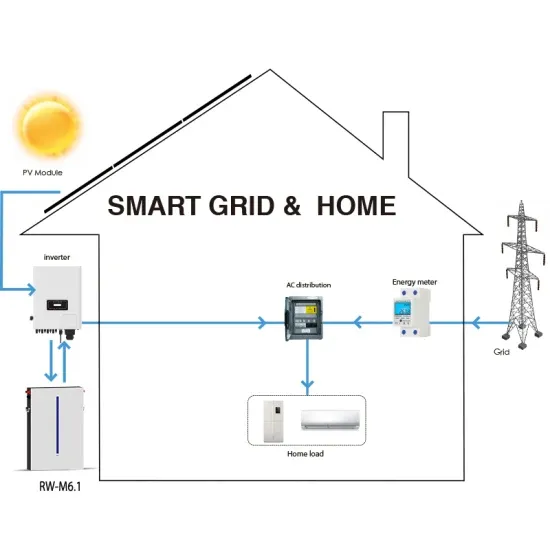

Optimum sizing and configuration of electrical system for

Typically, an electrical system of telecommunication base station consists of power sources such as grid power, solar power and generator power [4]. Fig. 1 illustrates a block

Get Price

Electric Power Generation, Transmission, and Distribution Industry

Describes five cases (six electrocutions) that resulted from the hazards of operating cranes near overhead power lines and makes recommendations for preventing similar incidents.

Get Price

Power Plant Construction Projects Risk Assessment:

With the proposed method, which has been tested in real industrial facilities, it has been possible to increase the safety of the system

Get Price

Power plant safety

Power plants are much safer than they once were; however, plant employees still encounter hazards. Training, along with proper operation and maintenance procedures, are

Get Price

Power station risk assessment

Process safety is very important on power stations due to hazards such as: fires or explosions following loss of fuel, explosions in high pressure steam

Get Price

Power Supply Safety Standards and Precautions | Bravo Electro

Electrical Shock: High-voltage power supplies generate dangerous current levels that can cause serious injury or death. Direct contact with live terminals, faulty wiring, or

Get Price

The 7 Best Portable Power Stations of 2025

Bring big backup power with you with these expert-recommended portable power stations, which can store enough power to charge electronics,

Get Price

Risk Factors of the Power Supply

Natural hazards include extreme weather, earthquakes, fire, epidemics/pandemics, and extraterrestrial hazards, while anthropogenic hazards include

Get Price

Ensure Safe Electrical Systems: Risk Assessments Guide

By systematically identifying hazards, analyzing their causes, and implementing targeted prevention and mitigation measures, these assessments safeguard personnel, equipment, and

Get Price

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

Introduction Hazard analysis involves the identification and quantification of the various hazards (unsafe conditions) that exist in the project site. In this chapter, an attempt has been made

Get Price

Ensure Safe Electrical Systems: Risk Assessments

By systematically identifying hazards, analyzing their causes, and implementing targeted prevention and mitigation measures, these assessments safeguard

Get Price

Identification Hazards and Risk Assessment in Power Plant

During this process, there are several hazards associated with it such as exposure to coal dust, noise, vibration, heat stress entanglement between conveyors; so as to avoid these hazards,

Get Price

Power station risk assessment

Process safety is very important on power stations due to hazards such as: fires or explosions following loss of fuel, explosions in high pressure steam equipment, catastrophic rupture of

Get Price

What Are the Risks Associated with Power Stations?

Power stations, while essential for energy generation, pose significant risks to workers and the surrounding environment. Key hazards include electrical shocks, chemical

Get Price

DEPARTMENT OF THE ARMY EM 385-1-1 U.S. Army Corps

> For complex or high hazard projects, the SSHO shall have a minimum of ten (10) years of safety-related work with at least five (5) years experience on similar type projects.

Get Price

Paper62 420..424

This paper will describe how a hazard identification and assessment methodology developed within the chemical sector has been applied to operational Power Stations.

Get Price

Power Supply Safety Standards and Precautions

Electrical Shock: High-voltage power supplies generate dangerous current levels that can cause serious injury or death. Direct contact with live

Get Price

Power Resilience: Guide for Water and Wastewater Utilities

Power loss can have devastating impacts on drinking water and wastewater utilities and the communities they serve. Inoperable pumps at a drinking water utility can make firefighting

Get Price

POWER GENERATION PLANT SAFETY GUIDE

POWER GENERATION PLANT SAFETY GUIDE Top Hazards in a Power Generation Plant Electrocution — Nearly 75% of all electrical work injuries are caused by arc flashes Boiler fire

Get Price

Power Plant Hazards

Hierarchy of Controls for Power Plant Hazards Elimination – Physically removing the hazard – this is the most effective hazard control. Consider moving a

Get Price

How to protect 5G macro base station amplifiers and antennas

This article describes macro base stations in detail and provides recommendations for protecting base station circuits, tower amplifiers and advanced antenna systems from sources of

Get Price

Risk Factors of the Power Supply

The hazard potential for critical infrastructures can be differentiated according to its focus on natural hazards and anthropogenic hazards. Natural hazards include extreme

Get Price

Renewable Energy Sources for Power Supply of Base Station Sites

An overview of research activity in the area of powering base station sites by means of renewable energy sources is given. It is shown that mobile network operators express significant interest

Get Price

Territory of Guam

This Energy Risk Profile examines the relative magnitude of the risks that the Territory of Guam''s energy infrastructure routinely encounters in comparison with the probable impacts. Natural

Get Price

6 FAQs about [Hazard sources in base station power supply projects]

What causes a process safety hazard in a power station?

Many power stations are being operated beyond their orig-inal design life increasing the risk of a process safety acci-dent due to the following factors. No hazard analysis during the design phase or records not available to the operating team. Process safety information incomplete, missing or out-of-date.

Why is a power supply a hazard?

This increases the risk of short circuits and electrical shock. Leakage Current: This refers to unintended current flow through the insulation or external parts of a power supply. It can pose a shock hazard, especially when sensitive equipment or personnel are involved.

What is a power plant risk assessment?

To make recommendations to mitigate the risk and hazards involved in the power plant. The goal of each risk assessment is to identify hazards, determine risk ranking with controls, and to revise the implementation of risk controls from the previous risk assessment sessions.

Does risk analysis improve safety in power plants?

The identification of hazards and risk assessment are key factors in the safety of the industries, including power plants. This paper contains an original risk analysis method that increases the level of safety in commissioning and start-up operations.

What are the power supply safety standards?

We’ll highlight the power supply safety standards below. At their most basic level, power supplies can be classified as one of three main categories based on their electrical insulation and grounding requirements. These are: Class I: Basic insulation and rely on grounding for safety.

Are you aware of power supply safety precautions?

You’re also aware of the safety concerns dealing with power supplies so you can protect yourself and others during installation, operation, maintenance, and replacement. Don’t overlook the power supply safety precautions we shared above.

More related information

-

Uninterrupted power supply for Nepal base station room

Uninterrupted power supply for Nepal base station room

-

Tajikistan 5G base station power supply and distribution facilities

Tajikistan 5G base station power supply and distribution facilities

-

Vaduz 5G base station power supply changed

Vaduz 5G base station power supply changed

-

What power supply does the base station outdoor cabinet provide

What power supply does the base station outdoor cabinet provide

-

Base station wind power supply and wind power generation module

Base station wind power supply and wind power generation module

-

Are there batteries in the power supply room of the telecom base station

Are there batteries in the power supply room of the telecom base station

-

What is the difference between base station power supply and ordinary power supply

What is the difference between base station power supply and ordinary power supply

-

Cambodia 5G base station power supply time

Cambodia 5G base station power supply time

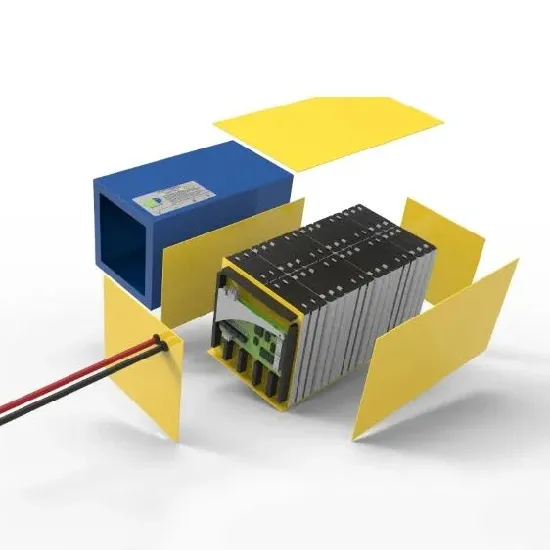

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.