Comprehensive Review of Crystalline Silicon Solar

This review addresses the growing need for the efficient recycling of crystalline silicon photovoltaic modules (PVMs), in the context of global

Get Price

Crystalline Silicon Photovoltaic Module Manufacturing Costs

This report updates c-Si PV supply-chain costs and projections generated from detailed bottom-up cost modeling at the National Renewable Energy Laboratory (NREL), which began in 2010

Get Price

Flow Chart of the Solar Panel Manufacturing Process:

Discover the solar panel manufacturing process flow chart that begins with quartz and ends with photovoltaic prodigies. Learn why crystalline

Get Price

List of photovoltaics companies

Photovoltaics companies include PV capital equipment producers, cell manufacturers, panel manufacturers and installers. The list does not include silicon manufacturing companies.

Get Price

Top 10 crystalline PV module manufacturer ranking

With production and capacity figures provided by industry analyst IHS Markit, pv magazine provides a rundown of the top 10 crystalline silicon

Get Price

Top 11 Solar Panel Manufacturers in China : 2025

Explore top solar panel manufacturers in China, production centers, and decisions on sourcing the best solar panels made in china.

Get Price

Perovskite Solar Cells: An In-Depth Guide

Perovskite vs. Crystalline silicon solar cells Crystalline silicon technology has been the norm for many decades in the solar industry. This is a matured technology with well

Get Price

Solar Panel Global Database | ENF Photovoltaic

Solar Panel Directory Welcome to the world''s most advanced solar panel (solar module) product directory. Solar installers, system integrators, and sellers can

Get Price

11 Best Solar Panel Manufacturers

Compare top solar panels for 2024: JinkoSolar, JA Solar, and more. Assess efficiency, warranty, and price to choose the best.

Get Price

PV Solar Cell Manufacturing Process & Equipment

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Get Price

Suntech

Suntech, founded in 2001, as a famous photovoltaic manufacturer in the world, is devoted to the R & D and the production of crystalline silicon solar cells and modules for 20 years.

Get Price

High-efficiency Module,Longi solar module

LONGi launched its mono-PERC modules in 2016, featuring integrated PERC technology on monocrystalline silicon and low light degradation, and its cell

Get Price

What are the crystalline silicon solar panel companies?

Each variant has distinct characteristics that affect its efficiency, cost, and application suitability. This analysis delves into the leading companies in the crystalline silicon

Get Price

Onyx Solar, Building Integrated Photovoltaics Solutions

Onyx Solar: Leader in Building Integrated PV Solutions. Custom Photovoltaic Glass for energy generation that enhances energy efficiency and reduces costs.

Get Price

Crystalline Silicon Photovoltaics Research

This simplified diagram shows the type of silicon cell that is most commonly manufactured. In a silicon solar cell, a layer of silicon absorbs light, which excites charged particles called

Get Price

Top 10 crystalline PV module manufacturer ranking

With production and capacity figures provided by industry analyst IHS Markit, pv magazine provides a rundown of the top 10 crystalline silicon module manufacturers based on

Get Price

High-efficiency Module,Longi solar module

LONGi launched its mono-PERC modules in 2016, featuring integrated PERC technology on monocrystalline silicon and low light degradation, and its cell efficiency has increased from

Get Price

Suntech

Suntech, founded in 2001, as a famous photovoltaic manufacturer in the world, is devoted to the R & D and the production of crystalline silicon solar cells and

Get Price

Crystalline Silicon Solar PV Companies

This report lists the top Crystalline Silicon Solar PV companies based on the 2023 & 2024 market share reports. Mordor Intelligence expert advisors conducted extensive research and identified

Get Price

Bila Solar

Bila Solar is redefining the industry with high-performance panels proudly manufactured in Indiana and ready to power your projects today. Bila Solar''s 550W dual-glass modules are built for

Get Price

Solar panel types and differences: monocrystalline silicon

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between monocrystalline, polycrystalline

Get Price

Solar PV Panels Market Size, Share & Trends Report,

The crystalline silicon segment is projected to grow at a substantial CAGR over the forecast period, owing to the lightweight and extended lifecycle of these

Get Price

Thin-Film Solar Panels: An In-Depth Guide | Types,

In 1980, researchers finally achieved a 10% efficiency, and by 1986 ARCO Solar released the G-4000, the first commercial thin-film solar

Get Price

Buy Monocrystalline Solar Panel Online Best Prices in

Top Leading Rooftop Solar EPC Company in India: A monocrystalline solar panel consists of monocrystalline solar cells. Mono

Get Price

Polycrystalline -

List of Polycrystalline solar panel manufacturers. Directory of companies that make Polycrystalline solar panels, including factory production and power ranges produced.

Get Price

Solar Photovoltaic Cell Basics

There are a variety of different semiconductor materials used in solar photovoltaic cells. Learn more about the most commonly-used materials.

Get Price

High-efficiency Module,Longi solar module

LONGi High-efficiency solar Module, widely adopting PERC solar cells technology, Half-cut Module Technology and Bifacial PV technology,Mono

Get Price

Bila Solar

Bila Solar is redefining the industry with high-performance panels proudly manufactured in Indiana and ready to power your projects today. Bila Solar''s

Get Price

6 FAQs about [Photovoltaic crystalline silicon panel manufacturer]

Where are the top ten polysilicon & solar module manufacturers?

According to EnergyTrend, the 2011 global top ten polysilicon, solar cell and solar module manufacturers by capacity were found in countries including People's Republic of China, United States, Taiwan, Germany, Japan, and Korea.

What is a monocrystalline silicon solar module?

Monocrystalline silicon represented 96% of global solar shipments in 2022, making it the most common absorber material in today’s solar modules. The remaining 4% consists of other materials, mostly cadmium telluride. Monocrystalline silicon PV cells can have energy conversion efficiencies higher than 27% in ideal laboratory conditions.

How are crystalline silicon solar modules made?

The manufacturing process for crystalline silicon solar module can be split into 4 main steps (read more about the silicon supply chain): Mined quartz is purified from silicon dioxide into solar-grade silicon. There are many smaller steps to this process, including heating up the quartz in an electric arc furnace.

Where are Bila solar panels made?

Manufactured in Indianapolis, Indiana, using U.S.-made components—including domestically produced solar cells—this durable, high-efficiency module is ready to deliver reliable energy for your projects today. Commercial metal rooftops with low static weight capacities are an ideal fit for Bila Solar’s ultralight laminated solar panels.

What are the different types of crystalline silicon solar cells?

There are several crystalline silicon solar cell types. Aluminum back surface field (Al-BSF) cells dominated the global market until approximately 2018 when passivated emitter rear contact (PERC) designs overtook them due to superior efficiency.

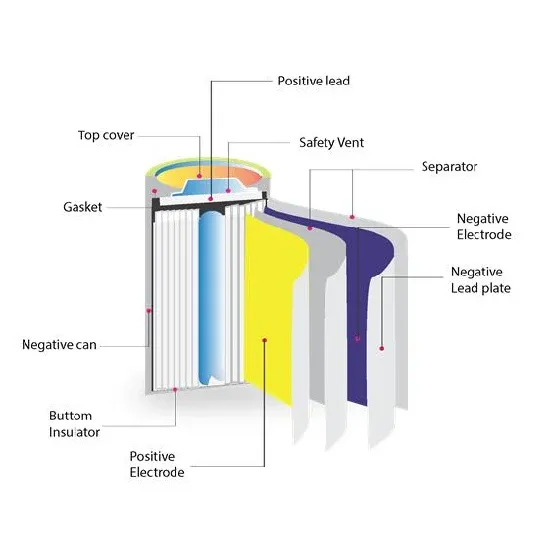

Which type of solar cell is most commonly manufactured?

This simplified diagram shows the type of silicon cell that is most commonly manufactured. In a silicon solar cell, a layer of silicon absorbs light, which excites charged particles called electrons. When the electrons move, they create an electric current.

More related information

-

Photovoltaic silicon panel manufacturer

Photovoltaic silicon panel manufacturer

-

Photovoltaic amorphous silicon panel manufacturer

Photovoltaic amorphous silicon panel manufacturer

-

Polycrystalline silicon photovoltaic panel manufacturer

Polycrystalline silicon photovoltaic panel manufacturer

-

Andor crystalline silicon photovoltaic panel wholesale

Andor crystalline silicon photovoltaic panel wholesale

-

Single silicon double glass photovoltaic panel manufacturer

Single silicon double glass photovoltaic panel manufacturer

-

Columbia Transparent Series Photovoltaic Solar Panel Crystalline Silicon

Columbia Transparent Series Photovoltaic Solar Panel Crystalline Silicon

-

Crystalline silicon solar panel curtain wall manufacturer

Crystalline silicon solar panel curtain wall manufacturer

-

Bhutan silicon solar photovoltaic panel manufacturer

Bhutan silicon solar photovoltaic panel manufacturer

Commercial & Industrial Solar Storage Market Growth

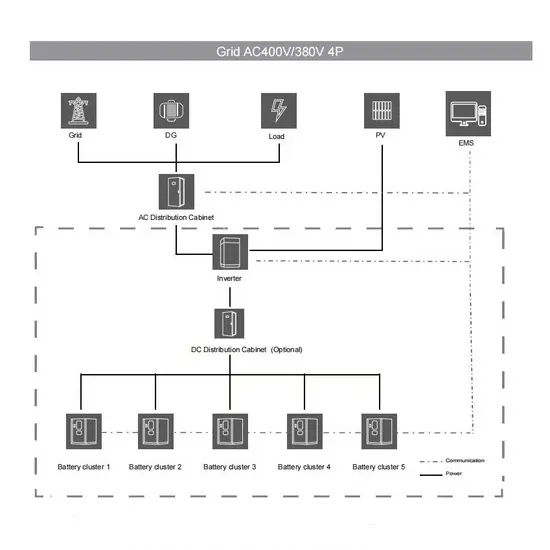

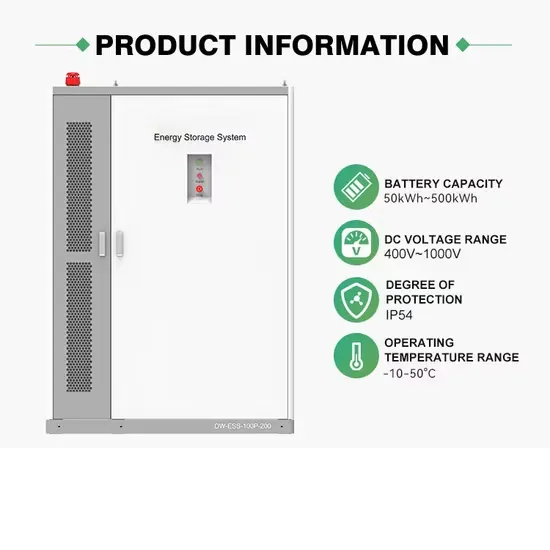

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.