Vodacom tests shipping container base station

They repackaged the base station equipment inside a compact steel structure that is then bolted to the roof of existing shipping container shops. This means that new sites can

Get Price

Best Materials To Put Under Shipping Containers

Concrete blocks provide a durable foundation for shipping containers but need proper leveling. Railroad ties are an affordable and eco-friendly alternative for temporary setups. Common

Get Price

Shipping Container Foundations: Complete Guide to Choose the Right Base

Learn when a shipping container needs a foundation, explore 10 types, and get expert tips to choose the right base for your container project.

Get Price

Shipping Container Foundations: Choosing The Right

Discover key tips for selecting the ideal foundation for your shipping container project. Ensure stability and longevity with our expert guide.

Get Price

What is Container Freight Station (CFS)?

What is a Container Freight Station (CFS)? Container Freight Station (CFS) is a facility where cargo is consolidated and deconsolidated for easy shipping. It serves as a

Get Price

Shipping Container Foundation and Footings – Do You Even

Below, we explore the most common base materials used for shipping containers, including gravel pads, concrete pads, dirt surfaces,

Get Price

20-Foot Mobile Equipment LUBESTATION

LUBESTATION containers are built for fast, easy and contamination-free lubrication storage and dispensary on remote work-sites. Improve the lifespan

Get Price

The Best Foundations for Shipping Containers

At Midstate Containers, we help you choose the best base for your shipping unit. We also offer advice and reliable products for both permanent and temporary setups to make

Get Price

The Best Foundations for Shipping Containers

At Midstate Containers, we help you choose the best base for your shipping unit. We also offer advice and reliable products for both permanent

Get Price

What''s the Best Material to Set a Shipping Container On?

Wondering what to set your shipping container on? Compare concrete, gravel, wood, and more to find the best foundation for stability and longevity.

Get Price

The Best Foundation for Shipping Containers | Boxhub

A solid foundation is essential for effective short- and long-term shipping container storage. Learn about the types of shipping container foundations here.

Get Price

Illinois officials demand answers from Noem, Hegseth on Navy base''s use

17 hours ago· Officials demand answers from Noem, Hegseth on Naval Station Great Lakes'' use for immigration arrests A letter obtained by the Sun-Times, to Defense Secretary Pete

Get Price

Container Station Quick Start Guide

Container Station is a virtualization platform developed by QNAP that allows you to effortlessly deploy and manage containerized applications

Get Price

Portable Container Type Fuel Station | For Future!

An expansion of the gas station can easily be made by just widening the access way and the container base and by mounting a second container. In order to

Get Price

The Best Foundation for Shipping Containers | Boxhub

A solid foundation is essential for effective short- and long-term shipping container storage. Learn about the types of shipping container

Get Price

Foundations for Shipping Containers: 4 Types and

To give you a better understanding of container footings overall, we''ll consider the four main types of foundations that are most widely used and appear to be the

Get Price

Storage Containers for Sale | 20'' and 40'' Conex

Repurposed containers for storage offer security, durability, and convenience for many organizations and can withstand nature''s brutal conditions.

Get Price

Types of Base Stations

Base stations are one of the widely used components in the field of wireless communication and networks. It is an access point or base point of a particular area for

Get Price

5 Best Foundations For Shipping Containers | Conexwest

We''ll take a look at some of the best foundations for shipping containers and why having a good foundation matters.

Get Price

Shipping Container Foundations: Complete Guide to

Learn when a shipping container needs a foundation, explore 10 types, and get expert tips to choose the right base for your container project.

Get Price

Choosing Shipping Container Foundation: A Complete Guide

Below, we explore the most common base materials used for shipping containers, including gravel pads, concrete pads, dirt surfaces, concrete blocks, and sono tube footings.

Get Price

No Grid Power? The HJ-SG Solar Container Keeps Base Stations

HJ-SG Solar Container provides reliable off-grid power for remote telecom base stations with solar, battery storage and backup diesel in one plug-and-play solution.

Get Price

Shipping Container Foundations: Choosing The Right Base

Discover key tips for selecting the ideal foundation for your shipping container project. Ensure stability and longevity with our expert guide.

Get Price

Station Container | EVE Wiki | Fandom

This is a Station Container. It is fitted with a password-protected security lock and computerized inventory auditing. Although the construction of a Station Container is much like that of other

Get Price

Storage Container

Storage Containers are used to provide additional storage in your base. Storage Containers allow a player to store resources and products above and beyond what is available in a starship or

Get Price

Shipping Container Foundation and Footings – Do You Even

Since pier foundations are economical, easy to install, and require minimal excavation, they''re arguably the best foundation for shipping container homes. If you decide

Get Price

Foundation Options for Shipping Container Structures

For single-unit containers in the same location long term, consider using a concrete foundation or a gravel pad. For many permanent applications, a concrete pad is likely the best

Get Price

How Outpost Storage Works — A Comprehensive Guide

On the 6-1 planet, when you make an extractor and power it up and put down your cargo link to your main base, your corresponding INCOMING cargo link back at your main base needs an

Get Price

Docker Hub Container Image Library | App

Welcome to the world''s largest container registry built for developers and open source contributors to find, use, and share their container images. Build, push

Get Price

Shipping Container Foundations Guide

Explore the different types of shipping container foundations, which one is right for your project, then how to design and build it!

Get Price

6 FAQs about [What base station is used for containers]

What are the most common base materials used for shipping containers?

Below, we explore the most common base materials used for shipping containers, including gravel pads, concrete pads, dirt surfaces, concrete blocks, and sono tube footings. 1. Gravel Pad: The Affordable and Effective Foundation A gravel pad is one of the most cost-effective and easiest foundations for a shipping container.

What is the best foundation for shipping container homes?

Since pier foundations are economical, easy to install, and require minimal excavation, they’re arguably the best foundation for shipping container homes. If you decide that you need some sort of basic foundation for your shipping container, a pier foundation will most likely be your best bet.

Why do shipping containers need a ground foundation?

Ground foundations act as anchor points for your structure, helping to distribute the shipping container weightevenly across the surface underneath, such as soil, concrete, gravel, or another substrate. Foundations are necessary for shipping containers since they can be placed almost anywhere.

What are the different types of shipping container foundations?

Shipping container foundations generally come in four main foundation types: pier, pile, slab, and strip. A concrete pier foundation consists of square blocks of steel-reinforced concrete which are placed under each of the container’s four corner castings.

Should a shipping container be placed on the Right Foundation?

Placing a shipping container on the right foundation will keep it level on a long-term basis. If your shipping container’s weight is not evenly distributed across its corner castings, your container may shift and warp over time, leading to serious structural problems.

How do you put a shipping container on top of concrete?

• Cement blocks: This approach is also known as “blocking”, and involves propping your shipping container on top of concrete blocks. The weight of the shipping container should keep the concrete foundation blocks firmly in place. Blocking is a quick and effective foundation for short-term container placements.

More related information

-

What control method is used for base station communication power supply

What control method is used for base station communication power supply

-

What base station batteries are used in hybrid energy

What base station batteries are used in hybrid energy

-

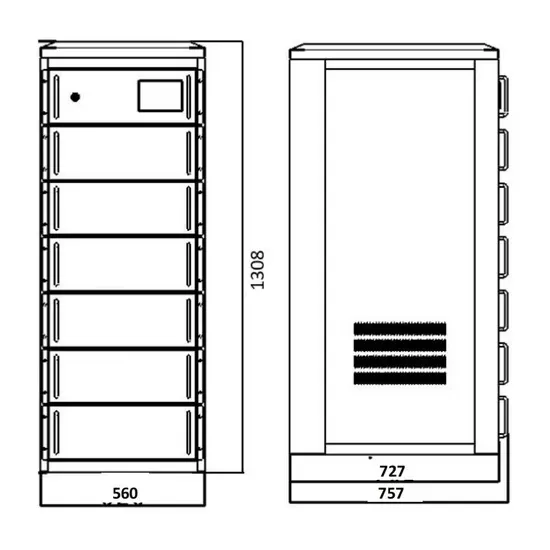

What to put in the base station power cabinet

What to put in the base station power cabinet

-

What is the best way to charge base station batteries

What is the best way to charge base station batteries

-

What systems does the communication base station wind power system include

What systems does the communication base station wind power system include

-

What is the role of base station energy storage batteries

What is the role of base station energy storage batteries

-

What kind of green base station does Zimbabwe use

What kind of green base station does Zimbabwe use

-

What are the base station communication equipment manufacturers

What are the base station communication equipment manufacturers

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.