Understanding Battery Management Systems

Key Functions of a BMS in Electric Vehicles Battery Monitoring – The BMS continuously monitors each battery cell''s parameters, which include

Get Price

Key Considerations Parameter Comparisons for BMS

This guide outlines essential selection criteria and compares key parameters based on technical requirements, application scenarios, and

Get Price

Best Battery Management System For Lithium ion

Let''s analyze the key parameters necessary for selecting the right battery management system for lithium ion batteries. The selection of an

Get Price

How does lithium-ion BMS work? | Redway Battery (US)

A Battery Management System (BMS) is an electronic system embedded within lithium-ion batteries to monitor, manage, and protect the battery cells. Its primary function is to

Get Price

Understanding lithium-ion battery management systems in electric

Voltage: Voltage monitoring stands out as an indistinguishable parameter in BMS. Typically, the BMS oversees voltage levels across each series group of cells to avoid

Get Price

Battery Management Systems for Lithium-Ion Packs

A Battery Management System (BMS) is essential for the efficient use and longevity of lithium-ion battery packs. It guarantees safety and performance by

Get Price

BMS Boards: A Practical Guide for Beginners and

For example, if a lithium – ion battery pack has a nominal voltage of 48V and can range from 40V to 54V during operation, the BMS board

Get Price

What are the Important Parameters of LiFePO4 Battery?

You can also set the over-charge voltage, over current, and other parameters. For example, you can set the discharge end voltage to 3.0V,

Get Price

Decoding BMS: Your Guide to Choosing the Perfect

Main Functions of BMS: Monitoring Battery Status: BMS measures and calculates vital parameters like battery voltage, current, temperature, power, SOC, SOH,

Get Price

Best Battery Management System For Lithium ion

Find out how to choose the right battery management system for lithium ion batteries by analyzing key parameters like voltage, current, and

Get Price

Best Battery Management System For Lithium ion Batteries

Let''s analyze the key parameters necessary for selecting the right battery management system for lithium ion batteries. The selection of an accurate battery

Get Price

How Lithium-ion Battery Management Systems Enhance Battery

The battery management system (BMS) maintains continuous surveillance of the battery''s status, encompassing critical parameters such as voltage, current, temperature, and state of charge

Get Price

How Lithium-ion Battery Management Systems Enhance

Now, let''s delve into how a BMS enhances the performance of lithium-ion batteries. The battery management system (BMS) maintains continuous surveillance of the battery''s status,

Get Price

Key Components Selection Guide for Battery

A battery management system (BMS) plays a critical role in ensuring the safety and performance of modern batteries. It monitors key

Get Price

Decoding BMS: Your Guide to Choosing the Perfect Battery

Main Functions of BMS: Monitoring Battery Status: BMS measures and calculates vital parameters like battery voltage, current, temperature, power, SOC, SOH, SOP, and SOE.

Get Price

What Is the Role of a Battery Management System (BMS) in Lithium

A Battery Management System (BMS) is essential for the safe and efficient operation of lithium-ion battery packs, particularly in applications such as electric vehicles and

Get Price

Your Guide to Battery Management Systems (BMS)

Lithium-ion batteries are expensive. So, make sure you protect them with a battery management system (BMS). This guide explores how a BMS works.

Get Price

EV Battery Efficiency''s Brain: Battery Management

A BMS serves three primary functions: Monitoring Battery Parameters: It continuously tracks key parameters like voltage, current,

Get Price

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

Monitoring Battery Health: A BMS continuously tracks key parameters of the battery, such as voltage, current, and temperature. This monitoring allows it to detect potential

Get Price

BMS settings for LiFePO4

Charge voltage: The charge voltage for a LiFePO4 battery should typically be set to around 3.6 volts per cell. This will ensure that the battery is charged to its full capacity while

Get Price

BMS for Lithium-Ion Batteries: The Essential Guide to Battery

The BMS continuously tracks vital parameters including voltage, current, temperature, and state of charge (SOC) across individual cells and the entire battery pack.

Get Price

BMS settings for LiFePO4

Charge voltage: The charge voltage for a LiFePO4 battery should typically be set to around 3.6 volts per cell. This will ensure that the battery is

Get Price

3. System design and BMS selection guide

The common battery parameters, such as the battery voltage, battery temperature and cell voltages can be monitored via Bluetooth using the VictronConnect app. However, state of

Get Price

Key Considerations Parameter Comparisons for BMS

This guide outlines essential selection criteria and compares key parameters based on technical requirements, application scenarios, and industry best practices.

Get Price

How to setup right parameters JK BMS | DIY Solar

When a battery is discharging it will draw voltage down and the Inverter should be set to stop Inverting at about 46V to 48V (2.875V to 3.0V

Get Price

Understanding the Role of the BMS in Modern Lithium Batteries

The BMS tracks the voltage of each cell in the pack, ensuring they stay within safe limits. If one cell drifts too high or low, the BMS can cut off charging or discharging to protect the battery.

Get Price

Lithium Battery Management Systems

Technical Update Lithium Battery Management Systems re maximum safety and performance. The BMS is designed to keep a battery within safe operating parameters by monitorin voltage,

Get Price

More related information

-

Tajikistan lithium iron phosphate BMS battery

Tajikistan lithium iron phosphate BMS battery

-

What is the charging voltage of a 7 2v lithium battery pack

What is the charging voltage of a 7 2v lithium battery pack

-

Lithium battery pack operating voltage

Lithium battery pack operating voltage

-

72 volt lithium battery bms

72 volt lithium battery bms

-

North American new energy lithium battery BMS module

North American new energy lithium battery BMS module

-

Develop lithium battery BMS

Develop lithium battery BMS

-

Huawei UAE high voltage energy storage lithium battery price

Huawei UAE high voltage energy storage lithium battery price

-

What is the voltage of a square lithium battery

What is the voltage of a square lithium battery

Commercial & Industrial Solar Storage Market Growth

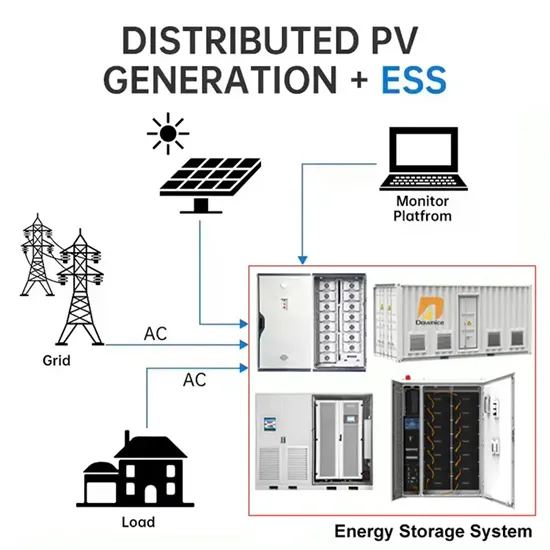

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

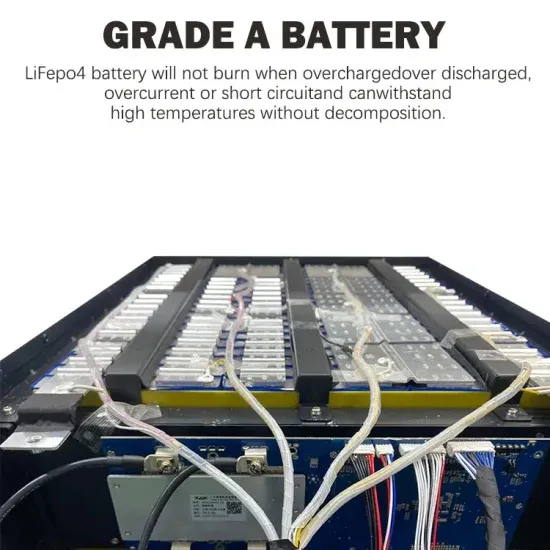

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.