Flywheel energy storage system price per KW

The total cost can be broken down into the following categories: (1) ESS cost, which is actually the overnight capital cost of the storage unit and can be divided into two parts, namely cost per

Get Price

RotorVault Energy Storage Cost Analysis and Flywheel Price

RotorVault Flywheel Cost-Competitive Technology RotorVault''s storage product for data center applications is the most cost-competitive solution offering both backup power for critical IT and

Get Price

Cost-Benefit Analysis of Flywheel Energy Storage in context of flywheel

Conducting detailed cost-benefit analyses for specific FES applications, such as frequency regulation or renewable energy integration. Investigating the impact of FES on grid

Get Price

Industrial Solutions Flywheel UPS Systems, 50-1000 kVA

How the Flywheel Works The flywheel energy storage system works like a dynamic battery that stores energy by spinning a mass around an axis. Electrical input spins the flywheel hub up to

Get Price

Flywheel energy storage construction cost budget

Building an energy storage station for new energy generation side can not only solve the fluctuation problem of new energy grid connection, but also increase the grid connection of

Get Price

Cost-Benefit Analysis of Flywheel Energy Storage in context of

Conducting detailed cost-benefit analyses for specific FES applications, such as frequency regulation or renewable energy integration. Investigating the impact of FES on grid

Get Price

RotorVault Energy Storage Cost Analysis and Flywheel Price

Explore RotorVault''s cost-competitiveness and scalability. A comparative cost analysis with Battery and Flywheel Energy Storage Systems.

Get Price

The development of a techno-economic model for the

After determining the size and capacities of different components, we developed the cost functions for individual pieces of equipment to determine techno-economic performance

Get Price

Bangladesh Huijue Energy Storage Construction: Powering a

A monsoon storm knocks out power lines across Dhaka, but hospitals keep running smoothly thanks to stored energy reserves. This isn''t science fiction – it''s the future

Get Price

Flywheel energy storage construction project

MW flywheel energy storage project located in Tunliu District, Changzhi City, Shanxi Province. This project The speed of the flywheel undergoes the state of charge, increasing during the

Get Price

The role of energy storage technologies for sustainability in

The primary energy storage types include hydro pumped storage, battery, flywheel, and compressed air storage, which can supply energy during peak-demand hours. However,

Get Price

The Flywheel Energy Storage System: A Conceptual Study,

The Cost of the FES Project The cost for the flywheel energy system varies based on the need for storage, with the difference in the design of the proposed flywheel system.

Get Price

Flywheel Energy Storage Costs: Breaking Down the Economics

Notice how per-unit costs decrease with scale - the 10 MW Jinan project achieved 18% lower per-MW pricing than smaller installations. This scaling effect mirrors what we''ve seen in solar PV

Get Price

Flywheel Energy Storage Costs Decoded: A 2024 Price Analysis

Why Should You Care About Flywheel Project Economics? If you''re reading this, you''re probably wondering: "How much does a flywheel energy storage project ACTUALLY

Get Price

A review of energy storage types, applications and recent

Recent research on new energy storage types as well as important advances and developments in energy storage, are also included throughout.

Get Price

The Status and Future of Flywheel Energy Storage

Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

Get Price

flywheel energy storage cost per kwh

Flywheel energy storage NASA G2 flywheel. Flywheel energy storage (FES) These spin at up to 37,800 rpm, and each 100 kW (130 hp) unit can store 11 megajoules (3.1 kWh) of re-usable

Get Price

High-tension, vertical filament winding enables

French startup Energiestro''s prototype solar energy flywheel-based storage system aims to reduce costs with glass fiber composites and

Get Price

Flywheel Storage Cost per kWh: A Sustainable Energy Revolution

As renewable energy adoption surges worldwide, the flywheel storage cost per kWh has become a critical metric for industries and governments. Traditional lithium-ion batteries, while popular,

Get Price

Top 5 Advanced Flywheel Energy Storage Startups in 2025

While non-toxic and highly efficient, traditional flywheel energy storage systems suffer from high capital costs and energy losses due to friction and power-hungry active magnetic bearings.

Get Price

Flywheel vs Battery Energy Storage Cost Analysis

Cost and Lifecycle Cost Comparison: This comparison simplifies the complexities of energy storage system economics. Actual costs and lifespans can vary significantly based

Get Price

Assessing the production cost for Flywheel Energy storage systems

Evaluate production costs at each BOM level by requesting supplier quotes, modeling parts, and collecting benchmarks.

Get Price

How much does a flywheel energy storage system cost?

Multiple elements contribute to the overall costs of flywheel energy storage systems. Firstly, the size and capacity of the installation greatly influence cost, with larger systems

Get Price

The 360 Gigawatts Reason to Boost Finance for Energy Storage

Storage is indispensable to the green energy revolution. The most abundant sources of renewable energy today are only intermittently available and need a steady, stored

Get Price

How much does a flywheel energy storage system cost?

Multiple elements contribute to the overall costs of flywheel energy storage systems. Firstly, the size and capacity of the installation greatly

Get Price

6 FAQs about [Bangladesh flywheel energy storage construction costs]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

Does a flywheel storage system need a bottom-up research?

However, almost no bottom-up research has been done, i.e., research that considers the technical parameters to size the components of a flywheel storage system, estimate cost parameters based on the design, and provide a probable distribution of the total investment cost and levelized cost of storage.

How much does a steel rotor flywheel cost?

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative to electro-chemical batteries for short-duration utility applications.

How many flywheels are required?

The corresponding number of flywheels required was calculated to be 200 and 186 (see Table 1). The TIC comprises total equipment cost, miscellaneous items cost, construction and commissioning cost, and contingency cost. The TEC, which comprises the costs of different components of the system, alone contributes about 68% to the TIC.

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

What is the largest flywheel energy storage?

The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration . Utility-scale flywheel storage is typically used for frequency regulation to maintain grid frequency by matching electricity supply and demand for a short period, usually 15 min , .

More related information

-

Flywheel energy storage equipment construction

Flywheel energy storage equipment construction

-

Energy storage and photovoltaic construction costs

Energy storage and photovoltaic construction costs

-

Flywheel energy storage does not meet construction requirements

Flywheel energy storage does not meet construction requirements

-

Southern Europe 5G flywheel energy storage construction project

Southern Europe 5G flywheel energy storage construction project

-

Egypt 5G flywheel energy storage construction project

Egypt 5G flywheel energy storage construction project

-

Australian flywheel energy storage construction standards

Australian flywheel energy storage construction standards

-

Oman flywheel energy storage production plant

Oman flywheel energy storage production plant

-

Energy Storage Charging Project Construction Plan

Energy Storage Charging Project Construction Plan

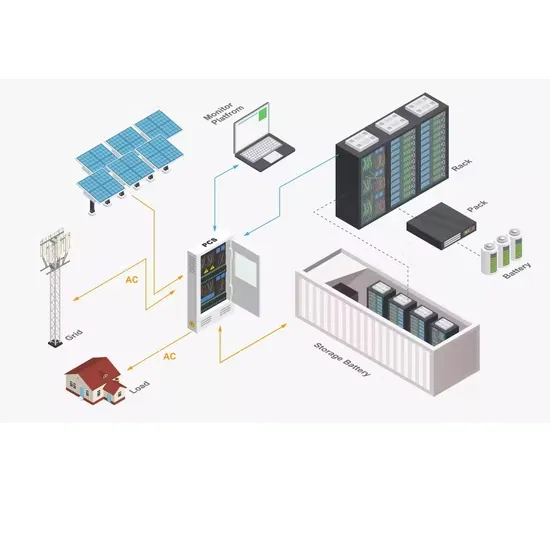

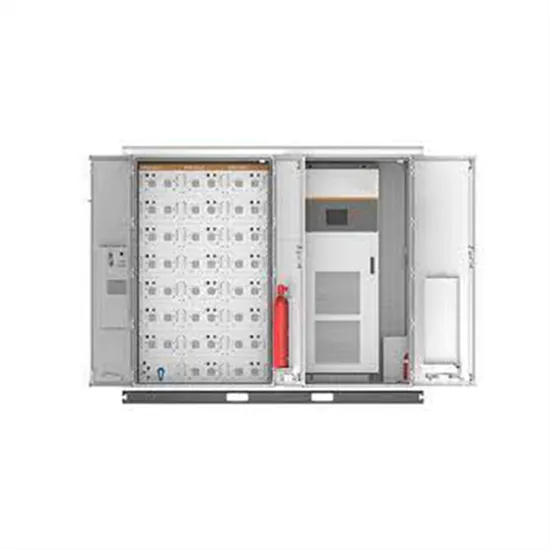

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

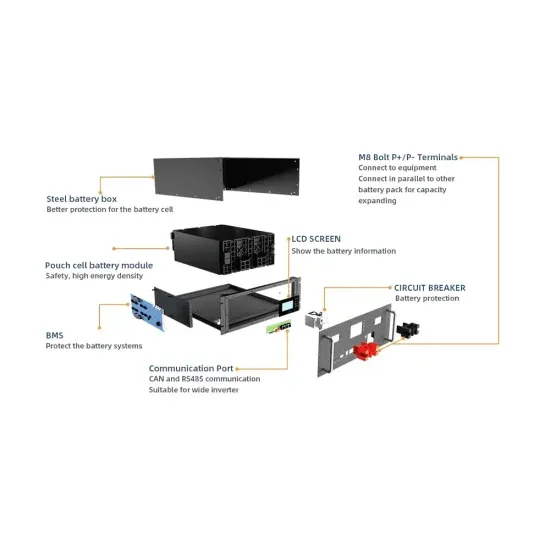

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.