Inversion Methods Explained: High Frequency vs Low Frequency

Size and tolerances of the transistors used in the inversion process, and the speed at which they operate determines the classification of high or low frequency. The large majority of inverters

Get Price

Understanding High-Frequency Inverters

In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to transform direct current

Get Price

High-Frequency Inverter: How They Work and Why

A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency,

Get Price

What is a High-Frequency Power Inverter?

What is a High-Frequency Power Inverter? - RayPCB. A power inverter converts DC power into AC power for operating AC loads and equipment. High-frequency power inverters utilize high

Get Price

Learn About High vs. Low Frequency Inverters: Which is Right for

High-frequency inverters have a much higher internal switching frequency than conventional low-frequency inverters - typically 20 kHz to 100 kHz. High-frequency inverters

Get Price

Understanding the Differences

Conclusion Whether opting for a low-frequency or high-frequency solar inverter depends on the individual''s specific requirements and priorities. Low-frequency inverters offer lower cost and

Get Price

Advantages of High-Frequency Inverters in Modern

High-frequency inverters are known for their high efficiency, which is one of their most significant advantages. By operating at higher frequencies, typically in

Get Price

High Frequency Vs. Low Frequency Inverters... Which is better?

High Frequency Vs. Low Frequency? Which Inverter is better?00:00 - intro00:43 - low frequency inverters02:15 - High Frequency Inverters03:17 - Comparison

Get Price

What is a High-Frequency Power Inverter?

What is a High-Frequency Power Inverter? - RayPCB. A power inverter converts DC power into AC power for operating AC loads and equipment. High

Get Price

High Frequency vs. Low Frequency Solar Inverters

Low-frequency inverters will take the low voltage current from the panels, and even when the sun is intense, and there are spikes in the system, there is a minimal power loss and

Get Price

Power Frequency Inverter vs. High Frequency

Power frequency inverter: Power frequency inverter usually refers to an inverter with an output frequency of 50Hz or 60Hz. Its working principle

Get Price

High Frequency vs. Low Frequency Inverter

A lot of the most popular AIO inverters are High Frequency Transformerless. How important is it to use the correct family of transformer (high vs. low freq) for to power devices

Get Price

A Review on the Recent Development of High

With the demand for the miniaturization and integration of wireless power transfer (WPT) systems, higher frequency is gradually becoming the

Get Price

Frequency Inverter Basic: Introduction, Functions and Advantages

The frequency inverter is a power control equipment that applies frequency conversion technology and microelectronics technology to control AC motors by changing the

Get Price

Surge vs. Efficiency: Choosing Between Low and High

In a typical high-frequency design, the incoming DC voltage is first chopped by a high-frequency DC-DC converter. This stage uses fast-switching power semiconductors, such

Get Price

High-Frequency vs. Low-Frequency Inverters

The inverter steps up the voltage using lightweight transformers or inductors, followed by the conversion to AC. Low-Frequency Inverters: Low-frequency inverters use heavy, iron-core

Get Price

Learn About High vs. Low Frequency Inverters: Which

High-frequency inverters have a much higher internal switching frequency than conventional low-frequency inverters - typically 20 kHz to 100

Get Price

Understanding inverter frequency – effects and adjustments

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical implications.

Get Price

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

In a typical high-frequency design, the incoming DC voltage is first chopped by a high-frequency DC-DC converter. This stage uses fast-switching power semiconductors, such

Get Price

A High-Frequency Inverter for Variable-Load Operation

This paper presents a new inverter architecture suitable for driving widely varying load impedances at high frequency (HF, 3-30 MHz) and above. We present the underlying

Get Price

High-Frequency Inverter: How They Work and Why They Matter

A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency, typically above 20 kHz (Kilohertz), to achieve

Get Price

Low Frequency Inverter, High Frequency Inverter,

* Low frequency inverter using powerful electrical appliances and equipment * Only small appliances need power supply, or your inverter space

Get Price

MIT Open Access Articles A High Frequency Inverter for

This paper presents a high-frequency inverter system that can directly drive widely-varying load impedances with high efficiency and fast dynamic response. Based on the architecture

Get Price

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for

Get Price

Low vs High frequency inverters

Small high frequency ferrite core transformers saturate quickly giving little time for any overload detection circuitry to react and shutdown inverter to save MOSFET drivers. Also

Get Price

High frequency vs low frequency pure sine wave inverter

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few million Hz. Low frequency

Get Price

Power Frequency Inverter vs. High Frequency Inverter: Which is

Power frequency inverter: Power frequency inverter usually refers to an inverter with an output frequency of 50Hz or 60Hz. Its working principle is to convert DC power into AC

Get Price

High frequency vs low frequency pure sine wave

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few

Get Price

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get Price

Design and Development of High Frequency Inverter for

In these applications, the optimal converter design is essential for handling the high power and frequency operation. In this paper, Simulation & Hardware development of High frequency

Get Price

More related information

-

Number of turns of high frequency inverter

Number of turns of high frequency inverter

-

Cyprus high frequency inverter manufacturer

Cyprus high frequency inverter manufacturer

-

Morocco high frequency inverter installation factory

Morocco high frequency inverter installation factory

-

Eritrea high frequency inverter

Eritrea high frequency inverter

-

Austria high frequency power inverter

Austria high frequency power inverter

-

Lesotho high frequency inverter manufacturer

Lesotho high frequency inverter manufacturer

-

Inverter high frequency modulation

Inverter high frequency modulation

-

High frequency inverter parallel operation

High frequency inverter parallel operation

Commercial & Industrial Solar Storage Market Growth

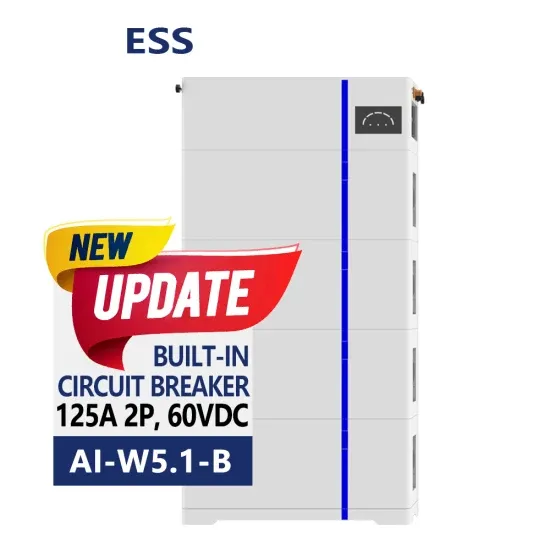

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.