Solar Panel Technologies for Light-to-Chemical Conversion

This wide reaction scope introduces new challenges toward quantifying and comparing the performance of different systems. To this end, we propose new metrics to

Get Price

U.S. Solar Photovoltaic Manufacturing

Solar PV devices use semiconducting materials, mainly crystalline silicon (CS), to convert sunlight to electricity. The solar CS PV value chain comprises four primary stages of manufacturing,

Get Price

10 Top Solar Panel Manufacturers Worldwide [Updated 2025]

Which are the top 10 solar panel manufacturers worldwide for 2025? Find out who is producing the most solar panels: China, India, or the USA?

Get Price

The state of the art in photovoltaic materials and device research

Photovoltaic (PV) technology is crucial for the transition to a carbon-neutral and sustainable society. In this Review, we provide a comprehensive overview of PV materials and

Get Price

Solar Panel Rated vs. Actual Output – Why is it Lower?

Actually, solar panels produce less electricity when the temperature starts climbing. Solar panels need energy from the sun, not the heat. PV modules are designed to run only under specific

Get Price

Solar Panel Technologies for Light-to-Chemical Conversion

The sustainable synthesis of fuels and chemicals is key to attaining a carbon-neutral economy. This can be achieved by mimicking the light-harvesting and catalytic

Get Price

Best Solar Panels Of 2025 – Forbes Home

Looking for info on the best solar panels? Discover expert opinions and data-driven insights on solar energy solutions for your home and based on your needs.

Get Price

Pahal Solar

India''s First AI based Solar Modules Manufacturer - 2GW About Us Our Products N-Type TOPCon Bifacial Panels Our Products N-Type TOPCon Bifacial

Get Price

High Efficiency Solar Panels | Maxeon | SunPower

PVSC 2018. Invest with confidence, knowing that SunPower Maxeon panel quality is proven. In actual field testing across 8 years and 800,000 panels at

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get Price

Photon management for augmented photosynthesis

Photosynthetic microalgae could provide an ecologically sustainable route to produce solar biofuels and high-value chemicals. Here, the authors review various optical

Get Price

Green Synthesis of Silicon Carbide from Sugarcane

End-of-life (EOL) solar panels may become a source of hazardous waste although there are enormous benefits globally from the growth in solar

Get Price

Recycled silicon powder from end-of-life solar panels

Researchers in India have demonstrated a wet chemical process to recover silicon with high purity from end-of-life solar panels, which they

Get Price

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride, copper indium gallium

Get Price

50-Watt Monocrystalline Solar Panel for 12-Volt

Product Details About This Product SolarSynthesis 10-Watt Monocrystalline Photovoltaic PV Solar Panel Module for 12-Volt Battery Charging is delivered

Get Price

Review of silicon recovery in the photovoltaic industry

This article aims to provide a comprehensive review of the advancements in silicon recovery research and development within the photovoltaic industry over the last decade. It

Get Price

How to synthesize mc solar panels | NenPower

In summary, synthesizing MC solar panels is a multifaceted process that involves strategic material preparation, advanced deposition techniques, meticulous system integration,

Get Price

Analyzing the lifecycle of solar panels manufacturing, and

As articulated by Calì et al. (2022), the energy expended in the synthesis of purified silicon constitutes one of the most significant contributors to the overall environmental footprint of

Get Price

Green Synthesis of Copper Oxide Nanoparticles from Waste Solar Panels

We propose an innovative method to recycle copper from waste solar panels and convert it into copper oxide nanoparticles (CuONPs) using a green synthesis method.

Get Price

A practical green synthesis method of Ag NPs using rosy

Therefore, versatile thin sheets or coatings are now being used to improve the surface morphology and attributes of the solar panel materials in an effort to increase the energy

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Get Price

Silicon solar cell production

Only very recently has the industry grown to the point where intermediate products, such as solar grade silicon, solar silicon wafers, solar cells and solar panels are commodities

Get Price

The Manufacturing Process of Solar Panels: From Raw Materials

Discover the fascinating journey of solar panel creation, as we unveil the intricate steps in the manufacturing process from raw materials to energy.

Get Price

Solar Manufacturing Cost Analysis | Solar Market

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride,

Get Price

Production cycle of solar panels: an introduction

Sinovoltaics explains the the production cycle of solar PV modules from pieces of raw material to the final electricity-generating panel.

Get Price

Production cycle of solar panels: an introduction

Sinovoltaics explains the the production cycle of solar PV modules from pieces of raw material to the final electricity-generating panel.

Get Price

Comprehensive review of the material life cycle and sustainability

The contributions of our review paper can be summarized as follows: 1. A systematic literature review conducted on the manufacturing process of solar panels, encompassing extraction and

Get Price

6 FAQs about [Solar panel product synthesis rate]

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

How can solar-cell research and development solve the efficiency limits of PV technology?

Approaching the efficiency limits of PV technology requires material innovations and device designs that minimize these losses. Solar-cell research and development presents several solutions to these problems that are intimately related to the properties of the specific PV materials.

How are solar panels made?

The process of making solar panels starts by turning silicon into high-purity polysilicon. This step mainly uses the Siemens process, combining hydrogen and chlorine. Fenice Energy focuses on crystalline silicon. It’s the top material for solar panels used today. To make solar panels, we begin with silicon ingots.

What is solar-thermal manufacturing?

While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems. Those systems are comprised of PV modules, racking and wiring, power electronics, and system monitoring devices, all of which are manufactured. Learn how PV works.

What is a solar PV supply chain?

Those systems are comprised of PV modules, racking and wiring, power electronics, and system monitoring devices, all of which are manufactured. Learn how PV works. Read the Solar Photovoltaics Supply Chain Review, which explores the global solar PV supply chain and opportunities for developing U.S. manufacturing capacity.

How do you calculate solar-to-fuel conversion efficiency?

Performance Metrics Artificial photosynthesis systems are commonly evaluated by their solar-to-fuel conversion efficiency (η STF), which can be calculated using formula 1, where rproduct is the product rate, ΔG is the reaction’s Gibbs free energy (ΔG > 0), P is the total incident solar power, and A is the irradiated area.

More related information

-

Solar panel mineralization rate

Solar panel mineralization rate

-

Solar Panel Product Classification

Solar Panel Product Classification

-

Double-layer solar panel photovoltaic conversion rate

Double-layer solar panel photovoltaic conversion rate

-

Norwegian solar panel product manufacturer

Norwegian solar panel product manufacturer

-

Solar panel product quality

Solar panel product quality

-

Swaziland non-standard solar panel assembly flexible

Swaziland non-standard solar panel assembly flexible

-

China Glass Solar Panel Photovoltaic

China Glass Solar Panel Photovoltaic

-

How many watts does one solar panel generate

How many watts does one solar panel generate

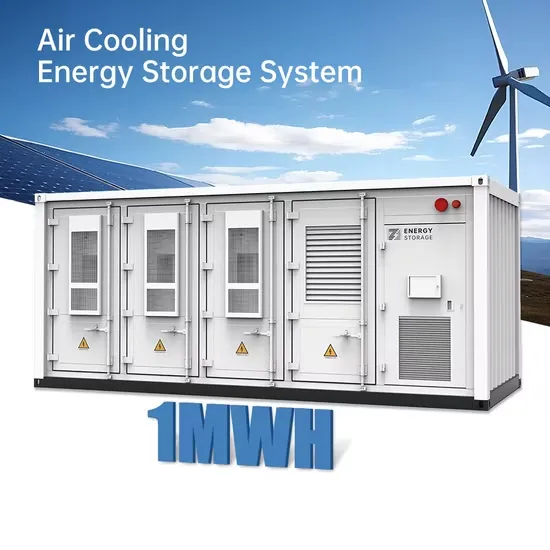

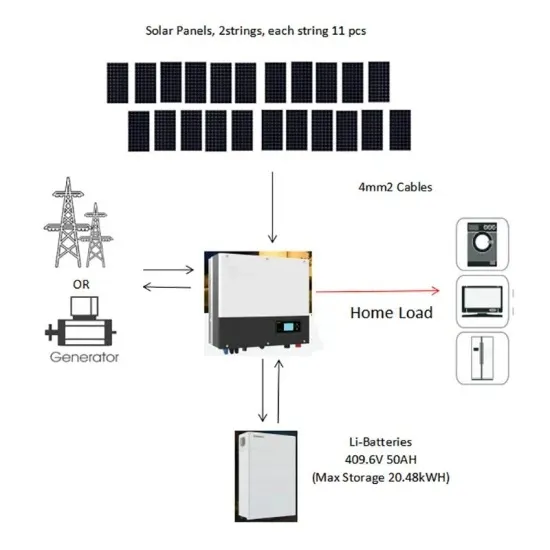

Commercial & Industrial Solar Storage Market Growth

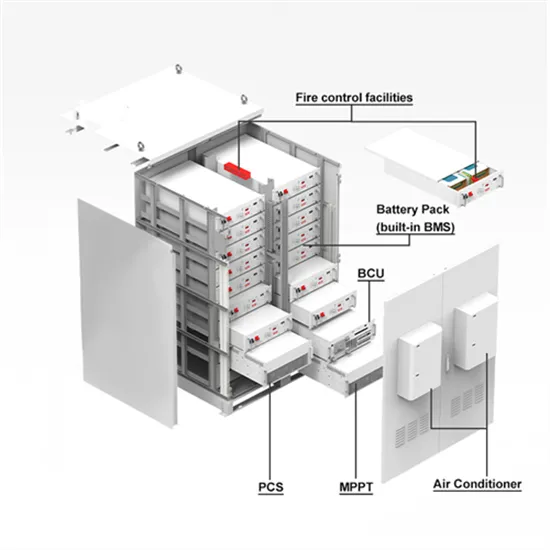

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

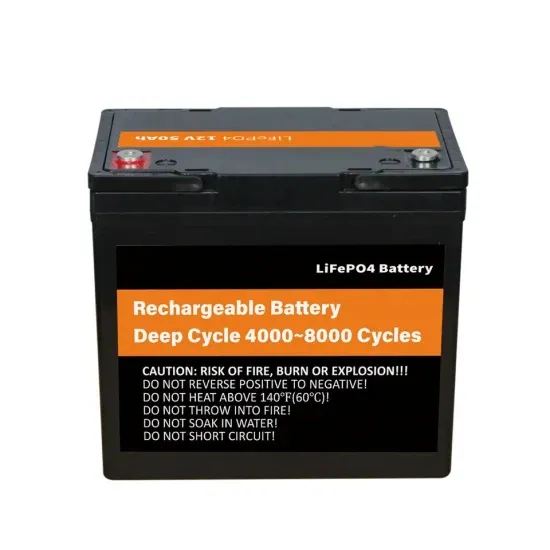

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.