Battery Charge And Discharge Calculator | Charge Time, Run

The Battery Charge and Discharge Calculator serves as a tool for anyone seeking to optimize energy management. This calculator enables you to accurately estimate the

Get Price

BU-501: Basics about Discharging

A discharge/charge cycle is commonly understood as the full discharge of a charged battery with subsequent recharge, but this is not

Get Price

China Battery Discharge Cabinet Manufacturers Suppliers

GOLDHOME is one of the most professional battery discharge cabinet manufacturers and suppliers in China. If you''re going to buy high quality battery discharge cabinet at competitive

Get Price

Battery Cabinet Current Limits | HuiJue Group E-Site

Have you ever wondered why battery cabinet current limits account for 43% of thermal runaway incidents in grid-scale storage systems? As renewable integration accelerates globally, the

Get Price

Battery Discharge Testing: A Comprehensive Guide to Testing

Here''s a table that shows the relationship between battery capacity, C-rate, discharge time, and discharge current for lead-acid, nickel, and lithium batteries.

Get Price

ESS continous switching between charge/discharge when battery

In the end the ESS determines when to charge and when to discharge not the battery. No the BMS should be in control of the battery. It tells the Cerbo and ESS the charge

Get Price

batteries

The "Battery University" says you should stop discharge at about 1.0 V per cell. That''s the level at which most of the energy in NiMH cells is exhausted. It is not a good idea to

Get Price

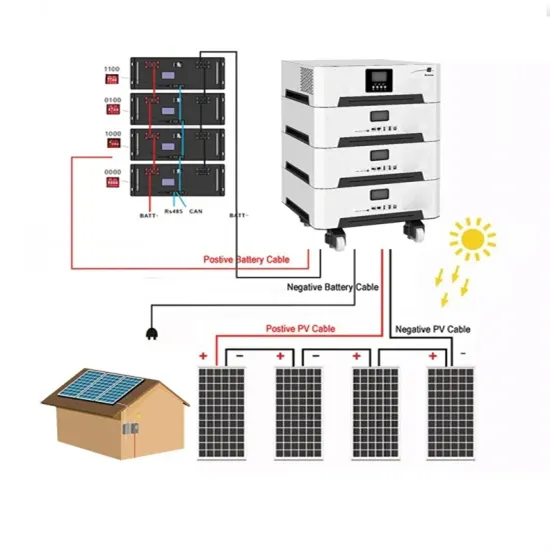

To charge a battery, a Cables with connectors are provided on the associated power system and the battery cabinet to allow simple interconnections between a battery cabinet and the

Get Price

Li-Ion Battery Safe Temperature: Everything You Should Know

Discover safe lithium-ion battery temperature limits for charging, storage, and cold weather performance.

Get Price

Battery Discharge Testing: A Comprehensive Guide to

Here''s a table that shows the relationship between battery capacity, C-rate, discharge time, and discharge current for lead-acid, nickel, and lithium

Get Price

Vertiv EnergyCore Battery System

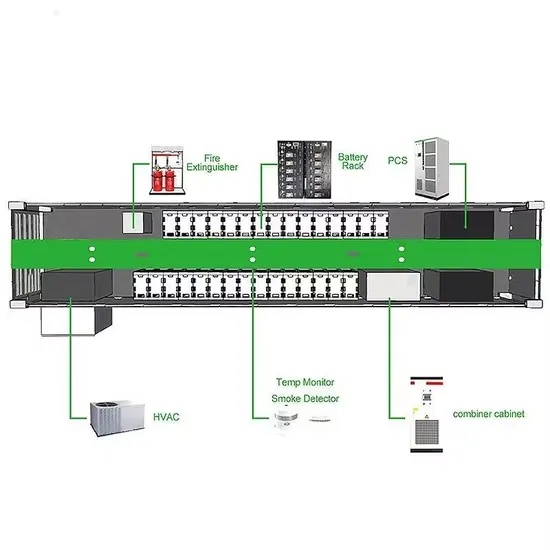

EnergyCore Battery Cabinet The Vertiv EnergyCore is the first lithium-ion battery cabinet engineered specifically for data center use. Its compact design, proven safety features, and

Get Price

Battery cabinet discharge current exceeds limit reason

Max Discharge Current (7 Min.) = 7.5 A; Max Short-Duration Discharge Current (10 Sec.) = 25.0 A; This means you should expect, at a discharge rate of 2.2 A, that the battery would have a

Get Price

Charge And Discharge Aging Cabinet BCDS Series

XW-BCDS 30-10-20 is mainly suitable for aging lithium battery packs such as solar street lamps, large capacity low-voltage energy storage, and electric tools.

Get Price

Battery Charging & Discharging: 10 Key Parameters

Whether you are an engineer designing power systems, a solar energy enthusiast, or just someone looking to get the most out of your

Get Price

Understanding Battery Discharge and Its Implications

A battery discharge occurs when the stored energy within a battery is released in the form of electrical current. It''s important to understand how and what causes a battery to

Get Price

BU-501: Basics about Discharging

A discharge/charge cycle is commonly understood as the full discharge of a charged battery with subsequent recharge, but this is not always the case. Batteries are

Get Price

Battery Charging & Discharging: 10 Key Parameters Explained

Whether you are an engineer designing power systems, a solar energy enthusiast, or just someone looking to get the most out of your batteries, this guide will break down the 10

Get Price

Fault Currents from Battery Energy Storage Systems charging vs

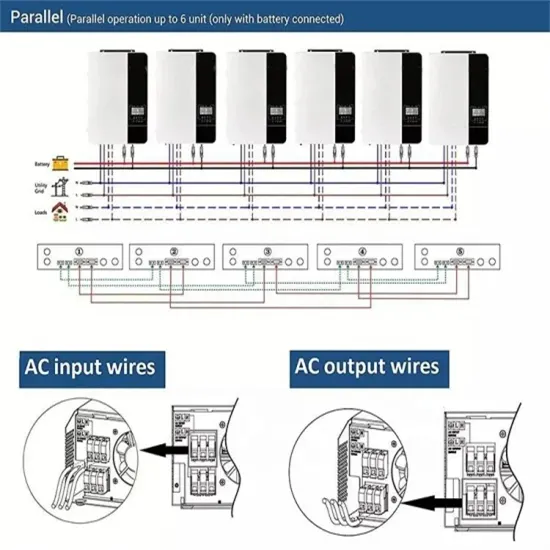

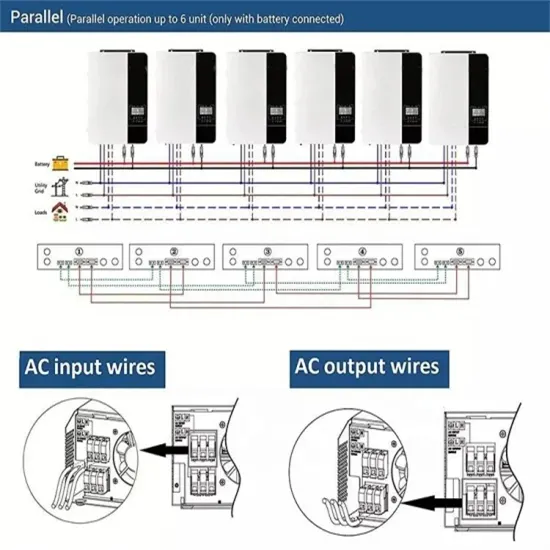

But a lower quality inverter may have trouble converting as battery voltage during discharge is reduced. And the battery internal resistance will increase, making it harder for the

Get Price

Universal Battery Discharger / Analyzer / Cycler | Amperis

The XMV is the perfect choice for battery manufacturing facilities, test and recovery laboratories and repair shops. The Digital Control XD can be programmed to discharge the battery with a

Get Price

Battery output current is unstable

Battery output current is unstable In cases where the input voltage is unstable or outside the recommended range, the use of a voltage regulator or a power conditioning device may be

Get Price

xd battery dc power supply cabinet

• Monitoring can automatically manage the battery voltage, charge and discharge current and battery temperature compensation accurately. It has over

Get Price

Common Lithium-ion Battery Problems and How to Fix Them

Partly, the loss is due to the large self-discharge of the battery itself. Solution: Manufacturers should check electrolyte suitability and assembly problems, while controlling

Get Price

Battery Cabinet

Easy capacity expansion: Batteries can be added along with load increase by stages. New and old battery cabinets can be connected in parallel. Easy maintenance:

Get Price

Li-Ion Cells: Charging and Discharging Explained

The discharge current is the amount of current drawn from the battery during use, measured in amperes (A). Li-ion cells can handle different

Get Price

Ultimate LiPo Battery Guide: How to Safely Charge,

This LiPo battery guide shows how to handle, charge, store and dispose of your LiPos. Avoid dangerous mistakes that can lead to a damaged

Get Price

About Battery Discharge You Need to Know

Battery discharge refers to the process by which a battery releases stored electrical energy when powering a system or device. When a battery is discharged, chemical reactions

Get Price

BU-501: Basics about Discharging

A high load current, as would be the case when drilling through concrete with a power tool, lowers the battery voltage and the end-of-discharge voltage threshold is often set

Get Price

6 FAQs about [Battery cabinet discharge current is unstable]

What happens if a battery is discharged after removing a load?

When removing the load after discharge, the voltage of a healthy battery gradually recovers and rises towards the nominal voltage. Differences in the affinity of metals in the electrodes produce this voltage potential even when the battery is empty. A parasitic load or high self-discharge prevents voltage recovery.

How much do satellite batteries charge and discharge?

A battery in a satellite has a typical DoD of 30–40 percent before the batteries are recharged during the satellite day. A new EV battery may only charge to 80 percent and discharge to 30 percent. This bandwidth gradually widens as the battery fades to provide identical driving distances. Avoiding full charges and discharges reduces battery stress.

What percentage of a battery should be discharged?

Shallow Discharge: Using only 20–30% of the battery’s capacity. Deep Discharge: Using 80–100% of the battery’s capacity. Deeper discharges can shorten the battery’s lifespan. For example, a battery cycled at 80% DoD may last only 500 cycles, while the same battery cycled at 20% DoD could last 2000 cycles.

Why does CCL not charge a battery?

CCL does not do that. Also see no reason why because as long as the voltage of the charger and the battery is the same there would be flowing no current anyway. In the end the ESS determines when to charge and when to discharge not the battery. In the end the ESS determines when to charge and when to discharge not the battery

What factors affect the discharge rate of a battery?

The discharge rate of a battery can be affected by a number of factors, including the load being placed on the battery, the age of the battery, and the temperature at which it is being used. A battery with a high discharge rate is able to deliver a large amount of electrical current in a short period of time.

What is battery discharge testing?

What is battery discharge testing ? Battery discharge testing, also known as battery load testing, is a process that test battery health statement by constant current discharging of the set value by continuously the discharge current from a fully charged state and then measuring how long the battery lasts.

More related information

-

Battery cabinet group voltage and current

Battery cabinet group voltage and current

-

The current of each module in the battery cabinet

The current of each module in the battery cabinet

-

Does the communication high voltage battery cabinet have current and how to connect it

Does the communication high voltage battery cabinet have current and how to connect it

-

How to solve the problem of battery cabinet current exceeding the limit

How to solve the problem of battery cabinet current exceeding the limit

-

How much current and voltage does the battery cabinet have

How much current and voltage does the battery cabinet have

-

What is the approximate current of the energy storage cabinet battery

What is the approximate current of the energy storage cabinet battery

-

How to discharge new energy battery cabinet

How to discharge new energy battery cabinet

-

Battery discharge current of communication base station

Battery discharge current of communication base station

Commercial & Industrial Solar Storage Market Growth

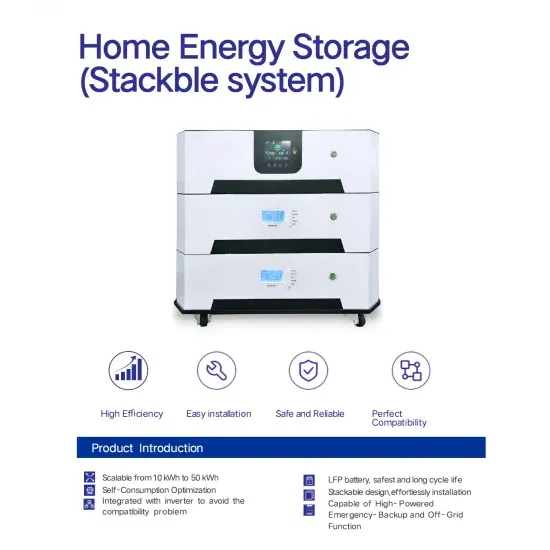

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.