Double the strengths, double the benefits

In contrast, double glass modules replace the polymer layer with another glass sheet, creating a robust sandwich structure. At IBC SOLAR, we use 2,0 mm x 2,0 mm glass

Get Price

Transparent backplane and double-glass solar panels:

Since glass accounts for a high proportion of the weight of solar panels, as the size of the module increases, the weight difference between double-sided transparent

Get Price

ECO LINE HJT GLASS-GLASS BIFACIAL

The highly efficient heterojunction technology, in combination with the glass-glass architecture, facilitate a new generation of high class solar modules. Due to a

Get Price

Q CELLS Data sheet Q.PEAK DUO XL-G10.d-BFG 475-490

BIFACIAL DOUBLE GLASS MODULE WITH EXCELLENT RELIABILITY AND ADDITIONAL YIELD BIFACIAL ENERGY YIELD GAIN OF UP TO 20 % Bifacial Q.ANTUM solar cells with

Get Price

Glass-Glass PV Modules

Although there is no standard on glass thickness, in general it is a more complex and expensive process to produce very thin, tempered glass. However, 2.5

Get Price

Aiko 460Wp Bifacial Glass-Glass N-Type PV panel

The double glass design (2.0 + 2.0 mm of coated semi-tempered glass) ensures superior mechanical resistance and greater protection against adverse environmental conditions. The

Get Price

What are the advantages of dual-glass Dualsun modules?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each.

Get Price

Emerging Double Glass PV Modules Trends and Opportunities

The global double glass PV module market is experiencing robust growth, driven by increasing demand for high-efficiency and durable solar energy solutions. The market''s

Get Price

JA Solar JAM72D42-630/LB N-Type Bifacial Double

The JA SOLAR JAM72D42-630/LB module is engineered to deliver exceptional performance in diverse environmental conditions. Its bifacial technology allows

Get Price

Specification

Never use a module with broken glass or top substrate. Broken modules should not be repaired and contact with any module surface can lead to electrical shock. Do not disassemble the

Get Price

Double the strengths, double the benefits

In contrast, double glass modules replace the polymer layer with another glass sheet, creating a robust sandwich structure. At IBC SOLAR, we

Get Price

Bifacial Solar Modules | Maysun Solar

Traditional monofacial panels use an opaque backsheet, whereas bifacial solar panels incorporate a reflective backsheet or a double-glass layer, enclosing the solar cells between these two

Get Price

Bifacial Solar Modules | Maysun Solar

Traditional monofacial panels use an opaque backsheet, whereas bifacial solar panels incorporate a reflective backsheet or a double-glass layer, enclosing

Get Price

INSTRUCTIONS FOR PREPARATION OF PAPERS

By choosing heat strengthened glass panels on both sides, we have been able to use a thickness of 2.5mm and to demonstrate an excellent module resistance to all standard mechanical tests

Get Price

210 Double Glass Module Series

210 Double Glass Module Series Dual-glass module is based on 210mm silicon wafer, high power, high efficiency, high compatibility, high quality and low

Get Price

What is the Double Glass Photovoltaic Solar Panel?

Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the traditional polymer backsheet. Originally

Get Price

双面双玻边框30mmJAM72D00 355-375 BP 加背面增益

Introduction These double-glass modules assembled with bifacial PERCIUM cells have capability of converting lights incident on their rear side into electricity on top of is being generated by the

Get Price

What are Double Glass Solar Panels?

The modules are available in two versions with power outputs of 525 W and 580 W. The dimensions of the small module are 2,142 mm x 1,160 x 29.6 mm and its weight is 30 kg.

Get Price

Glass-Glass PV Modules

Although there is no standard on glass thickness, in general it is a more complex and expensive process to produce very thin, tempered glass. However, 2.5 mm glass thickness does allow for

Get Price

Goodwe Introduces Double-Glass Topcon Bifacial Solar Modules

The modules are available in two versions with power outputs of 525 W and 580 W. The dimensions of the small module are 2,142 mm x 1,160 x 29.6 mm and its weight is 30 kg.

Get Price

去护角 158.9 JAM72D09 370-390 BP

Introduction JA bifacial modules are assembled by high-performance PERCIUM encapsulated by glass-glass panels, are capable of converting energy from lights on front and diffuse light, as

Get Price

What are Double Glass Solar Panels?

Double-glass solar modules are made up of two layers of tempered glass that cover both sides of the solar panel. As snow accumulates on a typical solar panel or people

Get Price

Double-glass PV modules with silicone encapsulation

Even more than for conventional modules, the bill of materials is critical for double-glass modules. In particular, the choice of encapsulant has a large impact on the module...

Get Price

D-Matrix Bifacial Double Glass Module

Double glass solar panels have longer average lives and are essentially PID-immune. D-Matrix Bifacial module is one of the examples from Das Solar.

Get Price

Double Glass PV Modules Market Size, Development, SWOT

Double Glass PV Modules Market Insights Double Glass PV Modules Market size is estimated to be USD 10.5 Billion in 2024 and is expected to reach USD 20.8 Billion by 2033 at a CAGR of

Get Price

6 FAQs about [What are the dimensions of the double-glass modules ]

What is a dual-glass module?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each. Some manufacturers, in order to reduce the weight of the modules, have opted for a thickness of 1.6 mm. DualSun has chosen to stay with a thickness of 2.0 mm for reasons explained below.

What is a double glass module?

The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum frame of conventional modules and frame-grounding requirements. The application of double-glass modules covers multiple markets including utility, residential and commercial.

What is the thickness of a glass module?

The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each.

Are double glass modules better than traditional modules?

Compared to traditional modules with backsheet, modules with double glass are stronger and more durable, presenting less degradation due to thermal cycling stress. Results from the thermal cycling test up to 400 cycles show about 35% to 43% less degradation with double- glass modules than with traditional modules with backsheet (Fig. 3).

Why are double glass modules symmetrical?

Mechanical constraints on cells: the fact that the structure of the double glass modules is symmetrical implies that the cells are located on a so-called neutral line, the upper part of the module being in compression during a downward mechanical load and the lower glass surface being in tension.

How much does a glass module weigh?

The weight of glass-glass modules are still an issue, with current designs using 2 mm thick glass on each side for framed modules, the weight is about 22 kg, while 2.5 mm on each side will increase the module’s weight to 23 kg. Compared to traditional glass-foil modules, which are about 18 kg, this is a 20% increase in weight.

More related information

-

Modules double-sided double-glass and double-sided single-glass

Modules double-sided double-glass and double-sided single-glass

-

Photovoltaic double-glass modules and bifacial modules

Photovoltaic double-glass modules and bifacial modules

-

What is monocrystalline silicon in photovoltaic modules

What is monocrystalline silicon in photovoltaic modules

-

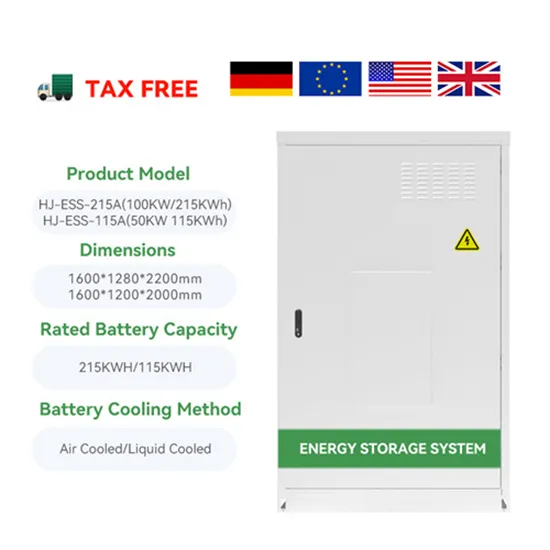

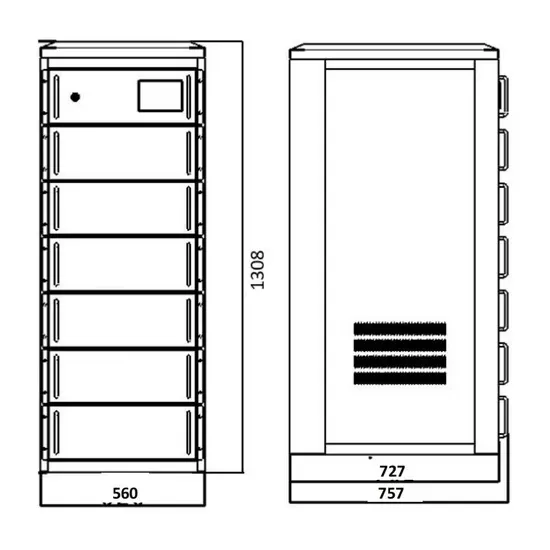

What are the dimensions and specifications of the floor-standing battery cabinet

What are the dimensions and specifications of the floor-standing battery cabinet

-

Huawei Congo double-glass photovoltaic modules

Huawei Congo double-glass photovoltaic modules

-

Greek double-glass modules

Greek double-glass modules

-

Photovoltaic double-glass cell modules

Photovoltaic double-glass cell modules

-

What are the dimensions of the energy storage container

What are the dimensions of the energy storage container

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

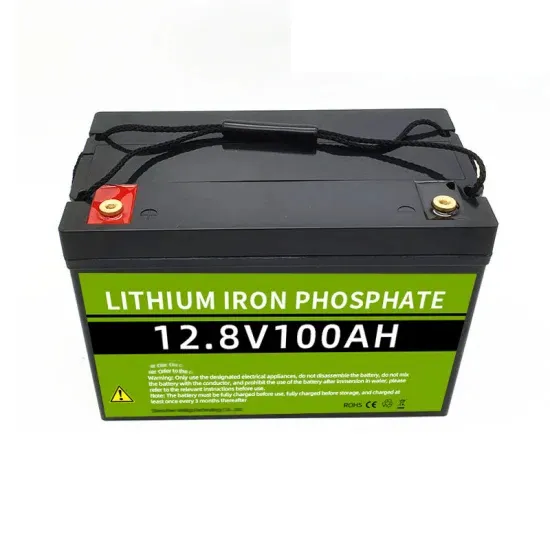

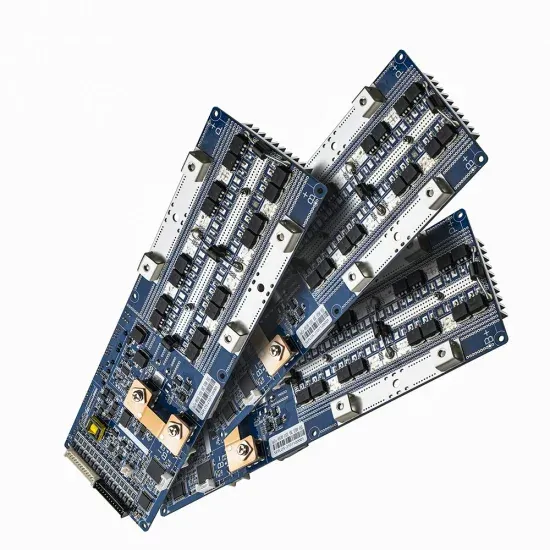

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.