Charging and Discharging of Lithium-Ion Battery

Learn how lithium-ion batteries charge and discharge, key components, and best practices to extend lifespan. Discover safe charging

Get Price

LiFePO4 Lithium-Ion Battery Pack Automatic Cycle

Automatic Cycle Testing: Streamlining the testing process, the equipment features automated cycle charge and discharge functionality. This automation

Get Price

Battery Charge&Discharge Test System-Welcome to

By editing test steps, the user may perform constant current charge, constant pressure charge and constant current/power/resistance discharge tests on

Get Price

1-24S EV Traction Lithium-Ion Battery Pack Automatic Charge Discharge

Lithium Battery Pack Charge Discharge Testing Equalizer can effectively solve EV shortened mileage problem resulting from the different capacity among the cells within the service life of

Get Price

12V-84V Lithium Battery Pack Automatic Cycle Charging Discharging

With a wide voltage detection range from 9V to 99V which make it can measure varieties of batteries from 12V-84V. Charging test and discharge test can be performed for lead-acid

Get Price

Regenerative Battery Pack Test System | Battery Charge Discharge

The regenerative battery pack test system is equipped with a bidirectional AC/DC converter, which can regenerate battery discharge energy to the AC power grid, saving power and testing

Get Price

Comprehensive Guide to Maximizing the Safety and

Explore an in-depth guide to safely charging and discharging Battery Energy Storage Systems (BESS). Learn key practices to enhance

Get Price

Battery Charge And Discharge Tester

HDGC3985 multi-purpose intelligent battery charging and discharging tester use to perform battery constant current discharge, intelligent charging and

Get Price

Battery Cell, Module, and Pack Cycler Test Equipment < Chroma

From power conversion to battery to electrical safety, our test systems will maximize your time, improve your validation process, and increase your throughput. High precision, integrated

Get Price

Understanding Charge-Discharge Curves of Li-ion Cells

This charge curve of a Lithium-ion cell plots various parameters such as voltage, charging time, charging current and charged capacity. When the cells are assembled as a

Get Price

Introduction to DJI Intelligent Flight Battery Auto-Discharging Rules

To figure out how the intelligent flight battery automatically discharges, you may need to learn the principles of two auto-discharging modes: self-discharge and auto-discharging function. Please

Get Price

Detailed explanation of battery charge and discharge

The charge and discharge tester is the most commonly used test equipment for power lithium batteries. New batteries need to be matched and

Get Price

Automatic Charging/Discharging Dual-Purpose Machine | 2V/6V/12V Battery

Discover the Automatic Charging/Discharging Dual-Purpose Machine, designed to activate and maintain 2V/6V/12V batteries, enhance battery pack capacity, and extend battery life.

Get Price

LiFePO4 Lithium-Ion Battery Pack Automatic Cycle Charge and Discharge

Automatic Cycle Testing: Streamlining the testing process, the equipment features automated cycle charge and discharge functionality. This automation enhances efficiency and consistency

Get Price

Lithium Ion Battery Testing Equipments

Providing you the best range of lithium-ion battery discharge tester, lithium-ion prismatic battery tester, lithium ion aging machine, neware cell tester 5v 100a 16ch, battery testing equipment

Get Price

(PDF) Charging and Discharging Control of Li-Ion

This paper presents an experimental study of the depth of discharge (DOD) and temperature distribution characteristics at different

Get Price

Automatic charging and discharging equilibrium device for battery pack

An automatic equalization, charging and discharging technology, which is applied to battery circuit devices, circuit devices, electric vehicles, etc., can solve the problems that the equalization

Get Price

Regenerative Battery Pack Test System | Battery

The regenerative battery pack test system is equipped with a bidirectional AC/DC converter, which can regenerate battery discharge energy to the AC power

Get Price

Lithium Battery Pack Tester DSF-20

Discover the DK Lithium Battery Pack Tester DSF-20, a top-tier solution for B2B suppliers. Ensure your EV batteries are tested with precision and reliability. Explore advanced features designed

Get Price

Lithium Battery Charge and Discharge Tester Analyzer Aging

The lithium battery charge and discharge capacity tester for finished battery pack is a smart and accurate device for battery pack production line. The aging cabinet is mainly used to test the

Get Price

100V60A 04CH Discharging and Charging Large Capacity Storage Battery

1 Year Product Description Product Description Introducing the HD-100V60A-04CH Battery Pack Tester, an intelligent solution designed for charge and discharge testing of various battery

Get Price

Lithium Battery Charge and Discharge Tester

The lithium battery charge and discharge capacity tester for finished battery pack is a smart and accurate device for battery pack production line. The aging

Get Price

CN102684262B

The automatic battery pack charging-discharging management device and the working method thereof have beneficial effects that the reliability of the entire system can be improved, the

Get Price

Li-Ion Cells: Charging and Discharging Explained

It''s crucial to know how to charge and discharge li-ion cells. This article will provide you with a guide on the principles, currents, voltages, and steps.

Get Price

6V/8V/12V VRLA/AGM/GEL Lead-Acid Battery

Charge-discharge characteristic online test for 6V/8V/12V batteries, online data analysis and comparison, fully compatible with Lead-acid, Lithium-ion,

Get Price

Battery Charge And Discharge Tester

HDGC3985 multi-purpose intelligent battery charging and discharging tester use to perform battery constant current discharge, intelligent charging and activation, which can reduce

Get Price

Battery Charging Discharging Machine,battery Grading Machine

120V 30A Power Battery / Battery Pack Tester for Charging and discharging and Capacity Testing of Cell 30V 30A 8 Channel Battery Tester for the Power Battery / Battery Pack

Get Price

Automatic Charging/Discharging Dual-Purpose Machine

Discover the Automatic Charging/Discharging Dual-Purpose Machine, designed to activate and maintain 2V/6V/12V batteries, enhance battery pack capacity, and extend battery life.

Get Price

99V 40A Lithium Battery Pack Auto Cycle Charge and

The Lead-Acid & Lithium Battery Series Charge Discharge Tester DSF40 is integrated with the function of a high-precision capacity series discharging test

Get Price

Battery Charge&Discharge Test System-Welcome to ITECH

By editing test steps, the user may perform constant current charge, constant pressure charge and constant current/power/resistance discharge tests on multi-channel cells or battery packs.

Get Price

6 FAQs about [Pack battery automatic charging and discharging]

What is the lithium battery charge and discharge capacity tester?

The lithium batterycharge and discharge capacity tester for finished battery pack is a smart and accurate device for battery pack production line. The aging cabinet is mainlyused to test the charging and discharging cycles of the finished lithiumbattery pack. The aging cabinet adopts PLC and industrial-grade touch screencontrol system.

What is a battery charge and discharge tester?

The battery charge and discharge tester for finished battery is a smart and accurate equipment. It is mainly used for the cycle charging and discharging testing of the finished lithium battery pack. Email: [email protected] Get a Free Quote Toggle navigationNAVIGATION Home About us Products Battery Insulation Cushion Machine

What is a battery charge & discharge monitor?

Real-time Charging & Discharging Monitor of Each Channel A battery pack is typically a set of cells connected in series which exhibit different characteristics during charge and discharge. For this reason, monitoring of cells is of great importance.

What is charge & discharge test?

Charging test and discharge test can be performed for lead-acid batteries, lithium batteries and other types of batteries. The maximum charge & discharge cycle index is 16 times, which can also be used as the aging equipment in battery production.

What is its5300 battery charge and discharge test system?

ITS5300 battery charge and discharge test system isdesigned for a variety of power batteries (lead acid, nickel hydrogen, lithiumbatteries, super capacitors, hydrogen fuel cells, etc.) for performancetesting.

What is the purpose of the 18650 battery charge and discharge capacity analyzer?

The 18650 batterycharge and discharge capacity analyzer is suitable for finished battery pack,include: power battery products, emergency power supply finished products, electricmotorcycle battery The lithium batteryaging testing machine Characteristic: 1.

More related information

-

Lithium battery pack 1000V high voltage charging and discharging

Lithium battery pack 1000V high voltage charging and discharging

-

Kiribati energy storage battery charging and discharging efficiency

Kiribati energy storage battery charging and discharging efficiency

-

18v solar panel directly charging 12v lithium battery pack

18v solar panel directly charging 12v lithium battery pack

-

Energy storage battery charging and discharging efficiency in Nigeria

Energy storage battery charging and discharging efficiency in Nigeria

-

Single charging of a series lithium battery pack

Single charging of a series lithium battery pack

-

Flow battery charging and discharging mode

Flow battery charging and discharging mode

-

Lithium battery pack charging and power off

Lithium battery pack charging and power off

-

Lithium battery pack ampere and volt

Lithium battery pack ampere and volt

Commercial & Industrial Solar Storage Market Growth

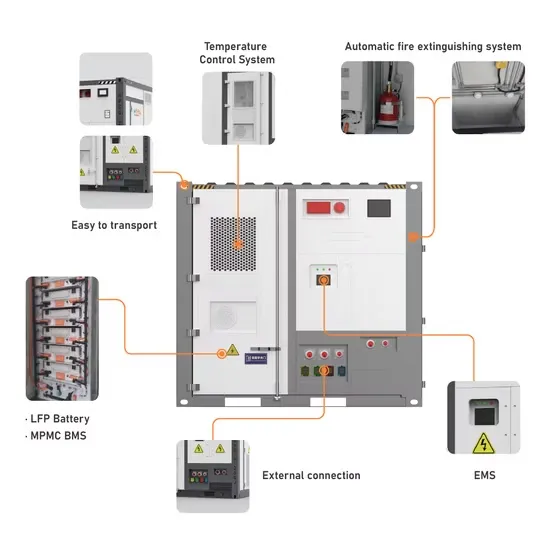

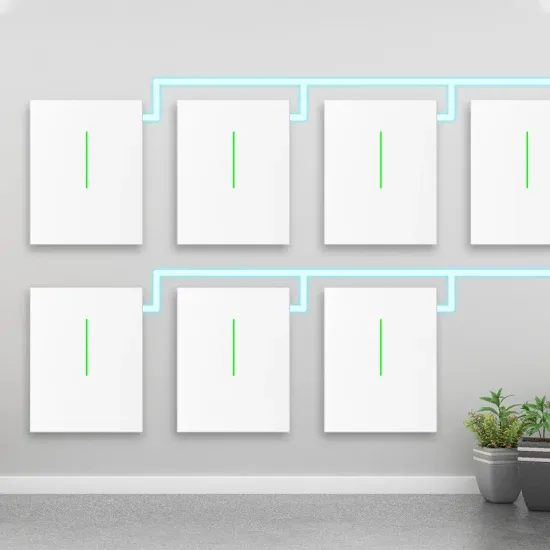

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

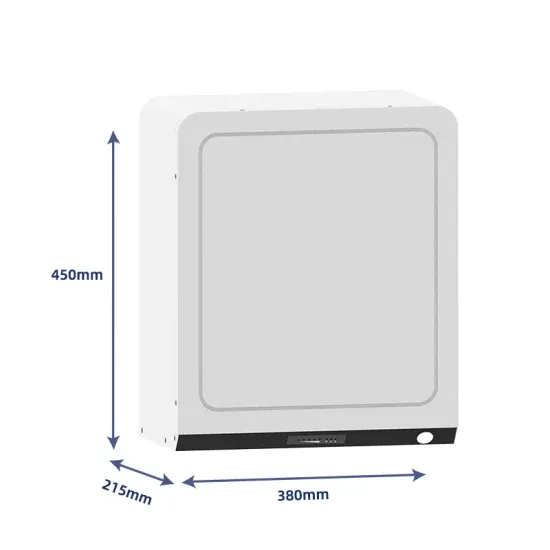

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.