Electrochemical Theory and Overview of Redox Flow Batteries

Compared to conventional (static) lead-acid batteries, RFBs are less costly to maintain and have longer lifetimes, exceeding 10 years. The modular nature of redox flow batteries enhances

Get Price

Analysis of different types of flow batteries in energy storage field

The fundamental difference between conventional and flow batteries is that energy is stored in the electrode material in conventional batteries, while in

Get Price

High performance and long cycle life neutral zinc-iron flow batteries

Abstract Zinc-based flow batteries have attracted tremendous attention owing to their outstanding advantages of high theoretical gravimetric capacity, low electrochemical

Get Price

Flow Batteries: Current Status and Trends | Chemical

Enabling Long-Life Aqueous Organic Redox Flow Batteries with a Highly Stable, Low Redox Potential Phenazine Anolyte. ACS Applied

Get Price

State-of-art of Flow Batteries: A Brief Overview

The flow battery systems incorporate redox mediators as charge carriers between the electrochemical reactor and external reservoirs. With the addition of solid active materials in

Get Price

Flow Batteries: Current Status and Trends | Chemical Reviews

Enabling Long-Life Aqueous Organic Redox Flow Batteries with a Highly Stable, Low Redox Potential Phenazine Anolyte. ACS Applied Materials & Interfaces 2024, 16 (1),

Get Price

Analysis of different types of flow batteries in energy storage field

Flow battery is a new type of storage battery, which is an electrochemical conversion device that uses the energy difference in the oxidation state of certain elements

Get Price

Progress and Perspectives of Flow Battery Technologies

To improve power and energy densities, researchers have started to investigate novel flow battery systems, including aqueous and non-aqueous

Get Price

Nickel alloys in electronics and batteries

Nickel (Ni) has long been widely used in batteries, most commonly in nickel cadmium (NiCd) and in the longer-lasting nickel metal hydride (NiMH) rechargeable batteries,

Get Price

Effects of trace amount of copper, nickel and bismuth on

In this work, the individual and combined effects of Cu, Ni and Bi on the activity of HER are explored. Specifically, when a current density on the scale of mA cm−2 is applied, the

Get Price

Mathematical modeling and numerical analysis of alkaline zinc-iron flow

The alkaline zinc-iron flow battery is an emerging electrochemical energy storage technology with huge potential, while the theoretical investigations are still absent, limiting

Get Price

3D Graphene–Ni Foam as an Advanced Electrode for High

Lijuan Zhao Qiang Ma Qian Xu Huaneng Su Weiqi Zhang Performance improvement of non-aqueous iron-vanadium flow battery using chromium oxide–modified

Get Price

Chelated Chromium Electrolyte Enabling High-Voltage Aqueous Flow Batteries

This work demonstrates two high-voltage aqueous flow batteries, including one operating at a non-hybrid record 2.13 V cell potential. These batteries utilize a negative

Get Price

Flow batteries

Depending on the different active species in the positive and negative half cells, RFBs can be classified into the following main types: the VRFBs, the sodium

Get Price

Progress and Perspectives of Flow Battery Technologies

To improve power and energy densities, researchers have started to investigate novel flow battery systems, including aqueous and non-aqueous systems. Here, novel non

Get Price

Flow Batteries

Flow batteries utilize the same structures as every other electrochemical device, namely two electrodes, a separator and an electrolyte. However, the reactants are stored as dissolved

Get Price

Material design and engineering of next-generation flow-battery

This Review highlights the latest innovative materials and their technical feasibility for next-generation flow batteries.

Get Price

Flow battery

The fundamental difference between conventional and flow batteries is that energy is stored in the electrode material in conventional batteries, while in flow batteries it is stored in the electrolyte.

Get Price

Iron chromium flow battery-Tycorun Batteries

With the transformation and adjustment of China''s energy structure, energy storage is facing unprecedented opportunities and explosive

Get Price

Electrocoagulation for nickel, chromium, and iron removal from

Therefore, this study aimed to determine the optimal combination of flow and inflow detention times for removing nickel, chromium, and iron from nickel mine industrial

Get Price

State-of-art of Flow Batteries: A Brief Overview

The flow battery systems incorporate redox mediators as charge carriers between the electrochemical reactor and external reservoirs. With the addition of solid

Get Price

Analyses and optimization of electrolyte concentration on the

TL;DR: In this paper, the effect of electrolyte concentration on the electrochemical performance of an iron-chromium flow battery was investigated, and it was shown that the electrolyte with 1.0

Get Price

Electrochemical Advances in Non-Aqueous Redox Flow Batteries

Electrochemistry has made a significant impact on scientific discovery and industrial development throughout recent history. One of the most important contributions of

Get Price

Advancing grid integration with redox flow batteries: an

ABSTRACT The widespread use of fossil fuels, along with rising environmental pollution, has underlined the critical need for effective energy storage technologies. Redox flow batteries

Get Price

Flow Batteries: Current Status and Trends | Chemical

This article is cited by 955 publications. Changkun Zhang, Zhizhang Yuan, Xianfeng Li. Designing Better Flow Batteries: An Overview on

Get Price

Comparing battery technologies: Nickel-H2 vs. Iron vs. Li-ion

A few such chemistries that have made big waves recently are EnerVenue''s nickel-hydrogen battery, ESS Inc''s iron flow battery and Form Energy''s iron-air battery. The following

Get Price

Evaluation of Tris-Bipyridine Chromium Complexes for

This paper presents structure−solubility−electrochemistry relationships for a series of tris-bipyridine chromium complexes with potential

Get Price

Chelated Chromium Electrolyte Enabling High-Voltage

This work demonstrates two high-voltage aqueous flow batteries, including one operating at a non-hybrid record 2.13 V cell potential. These

Get Price

What materials are used in nickel-chromium batteries

A few utilities began installing large-scale flow batteries in 2016 and 2017, but those batteries use a vanadium-based electrolyte rather than iron. Vanadium works well, but it''''s expensive.

Get Price

More related information

-

Nickel-chromium flow battery

Nickel-chromium flow battery

-

Solar Base Station Flow Battery Construction Plan

Solar Base Station Flow Battery Construction Plan

-

All-vanadium redox flow battery discharge rate

All-vanadium redox flow battery discharge rate

-

What is the price of chromium flow battery

What is the price of chromium flow battery

-

Bosnia and Herzegovina flow battery

Bosnia and Herzegovina flow battery

-

Location of flow battery solar base stations in The Gambia

Location of flow battery solar base stations in The Gambia

-

Flow Battery Professional

Flow Battery Professional

-

Flow battery device purchase

Flow battery device purchase

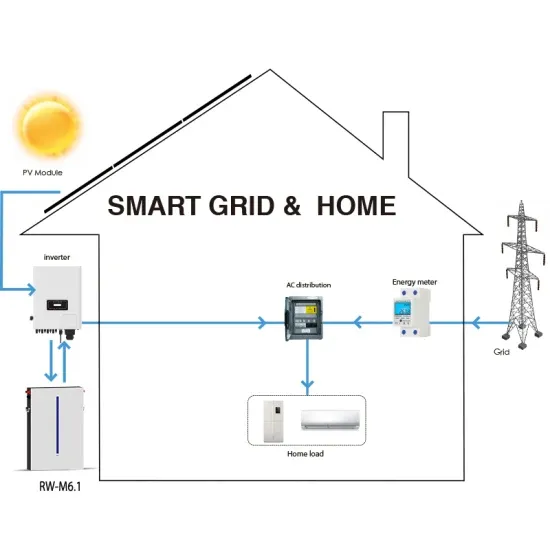

Commercial & Industrial Solar Storage Market Growth

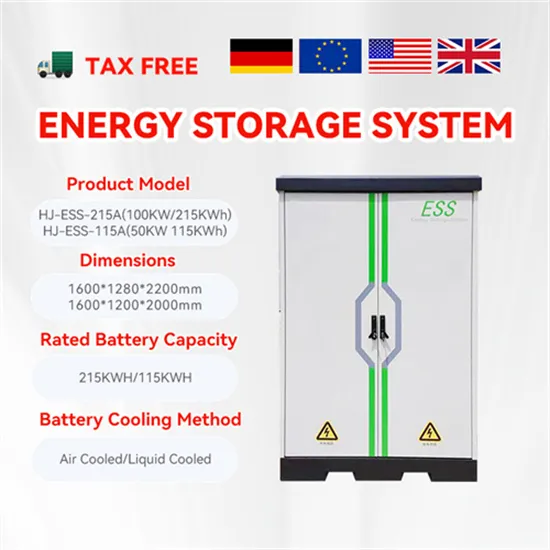

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

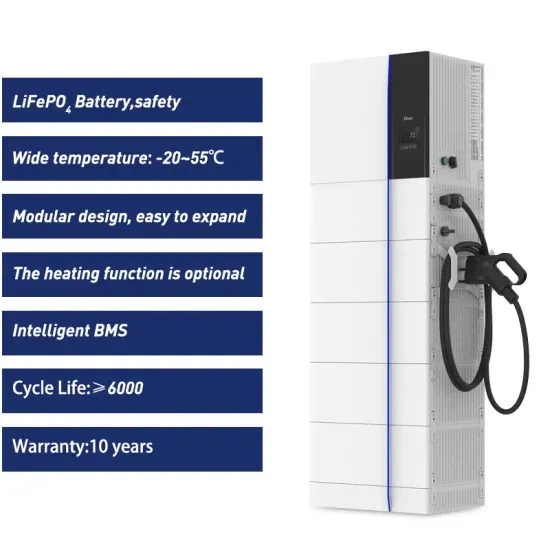

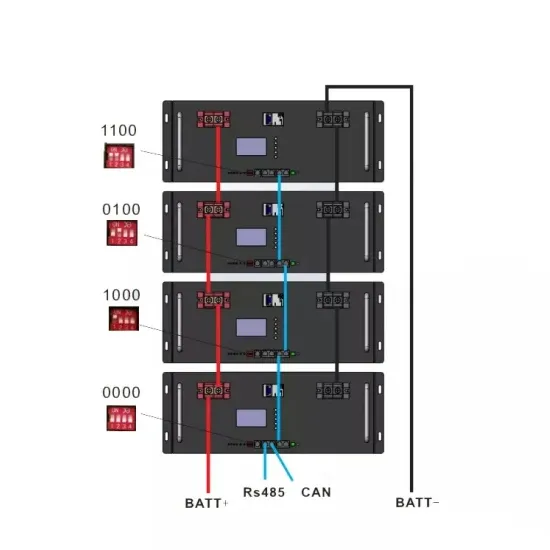

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.