Do You Need To Ground An Inverter? (Safe Measures)

Inverters should always be grounded to a single grounding point. A copper grounding rod must be driven into the ground outside and connected

Get Price

Grounding Power Inverters In Bedrooms: A Safe Guide

Grounding a power inverter is essential for safety, especially if you''re using it in an enclosed space like a bedroom. The process of grounding connects the inverter to the earth,

Get Price

7. Ground, earth and electrical safety

Grounding is needed for electric safety and it also creates a reference point in a circuit to which voltages are measured. Earth is a direct physical connection to the Earth. This is usually done

Get Price

Checking the PV System for Ground Faults

If a definite ground fault cannot be measured and the message is still displayed, measure the insulation resistance. Reconnect the strings without ground faults to the inverter and

Get Price

Insulation Resistance Testing in PV Systems

Insulation resistance testing is a non-destructive test procedure and does not cause harm to the conductors. The test measures the insulation resistance between the conductors and ground.

Get Price

Best Practices in PV System Ground Fault Testing —

Using a digital multimeter (DMM), technicians should measure voltage from positive to negative, positive to ground, and negative to ground.

Get Price

How to Measure DC Bus Voltage and DC Ripple

Some important protective functions derived from DC bus voltage are: Under voltage Over voltage DC bus ripple Oftentimes when a drive trips on under voltage or over

Get Price

Measurements on 3-Phase Motor Drives with an

This primer describes methods for making measurements using inverter, motor and drive analysis software on oscilloscopes to provide stable, accurate

Get Price

Why do engineers usually short ground and negative

I''m fairly new to electrical engineering, and have seen many DC power supplies where someone has shorted the ground (green) port with the

Get Price

How to Detect Ground Faults in Your PV System : Service Center

In this article, we''ll show you how to locate a ground fault in a solar PV string using only a multimixer, a basic understanding of voltage behaviour, and a method proven in real

Get Price

Solis Seminar 【Episode 55】: Using the piecewise method to

Troubleshooting Disconnect the DC switch of each PV string connected to the inverter. After 10 minutes, remove each PV string from the inverter and use a multi-meter to

Get Price

Best Practices in PV System Ground Fault Testing — Mayfield

Using a digital multimeter (DMM), technicians should measure voltage from positive to negative, positive to ground, and negative to ground. The readings will return

Get Price

Checking the PV System for Ground Faults

In order to check the PV system for ground faults, perform the following actions in the prescribed order. The exact procedure is described in the following sections. Check the PV system for

Get Price

7. Ground, earth and electrical safety

7. Ground, earth and electrical safety In this section 7.1. Electrical safety 7.2. Earth wiring 7.3. RCD, RCCB or GFCI 7.4. Neutral to earth link in inverters and in inverter/chargers 7.5. Mobile

Get Price

What happens if an inverter neutral is bonded to earth?

Does a flow of current between my inverter AC outlet neutral and the ground will be observed? Can this damage the unit or will everything be fine and will the potential between

Get Price

Inverter voltage measurements don''t make sense: phase voltage

Because of the way that inverter drives work, using PWM and not AC voltages as such at all, you will measure a lot of very strange numbers, many of them not related to very

Get Price

Insulation Resistance Measurement for the Safety of

For safer and more accurate measurements To safely measure the insulation resistance of PV modules, it is recommended to conduct the measurement

Get Price

How to Quickly and Effectively Determine "ground fault"

Disconnect the DC switch of each PV string connected to the inverter, and use a multi-meter to measure the voltage of the PV+ to ground

Get Price

Dangerous voltage between positive and ground (structure)

I checked the negative wire for any chaffing or anywhere that could cause a ground fault and found nothing. I then disconnected the -ve from the inverter and the voltage between the +ve

Get Price

Need some help with connecting to ground for my inverter!

Need some help with connecting to ground for my inverter! Really need some help... I am pretty worried about the safety of my system in its current state! I have an AIO

Get Price

What happens if an inverter neutral is bonded to earth?

Does a flow of current between my inverter AC outlet neutral and the ground will be observed? Can this damage the unit or will everything be

Get Price

How to Quickly and Effectively Determine "ground fault"

Disconnect the DC switch of each PV string connected to the inverter, and use a multi-meter to measure the voltage of the PV+ to ground and PV- to ground of each string.

Get Price

7. Ground, earth and electrical safety

In this article, we''ll show you how to locate a ground fault in a solar PV string using only a multimixer, a basic understanding of voltage behaviour,

Get Price

Technical Information

Since the leakage current is directly dependent on the capacitance of the PV module to ground, for each AC voltage to ground a capacitance limit can be specified, above which operation will

Get Price

Grounding Techniques to Prevent Inverter Damage

The average designed withstand voltage of solar inverters is 1750 volts between AC and ground and 500 volts between DC and ground. Your first step to grounding your

Get Price

DC-side High Impedance Ground Fault Detection for

With the fast development of the photovoltaic (PV) industry, techniques of improving solar cell efficiency, reliable and low cost inverter and advanced fault detection methods have been

Get Price

Grounding Techniques to Prevent Inverter Damage

The average designed withstand voltage of solar inverters is 1750 volts between AC and ground and 500 volts between DC and ground. Your

Get Price

Electrical testing standards guide for the PV Industry

Ground-fault detection is typically automated by devices within the PV inverter, alerting the technician to the fault''s presence. Locating the fault, however, is often challenging. This

Get Price

Do You Need To Ground An Inverter? (Safe Measures)

Inverters should always be grounded to a single grounding point. A copper grounding rod must be driven into the ground outside and connected to the single grounding

Get Price

Measuring the Insulation Resistance of PV Strings to the Ground

A low insulation resistance indicates poor insulation performance, which may cause personal safety and inverter performance problems. Therefore, before connecting PV strings to the

Get PriceCommercial & Industrial Solar Storage Market Growth

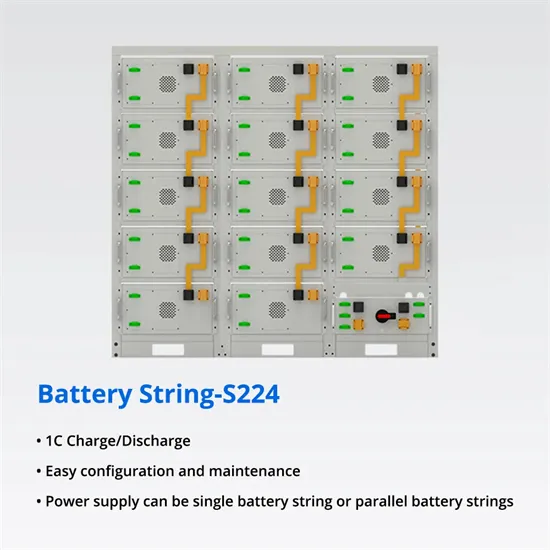

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

Inverter DC power measurement

Inverter DC power measurement

Inverter DC pump voltage

Inverter DC pump voltage

Industrial DC to AC inverter

Industrial DC to AC inverter

Seychelles DC Inverter

Seychelles DC Inverter

DC power photovoltaic inverter

DC power photovoltaic inverter

North Korea s best AC DC inverter

North Korea s best AC DC inverter

Inverter output 700V DC

Inverter output 700V DC

Huijue DC inverter 5KW

Huijue DC inverter 5KW