Advancements in high power high frequency transformer design

Medium and high frequency converters are gaining increasing interest for high power applications such as renewable energy and dc grids. Medium and high frequency transformers are an

Get Price

Understanding High-Frequency Inverters

In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to transform direct current

Get Price

Research on High-Frequency Isolated NPC Three-Level Inverter

To tackle these challenges, this paper presents a three-stage topology for high-frequency isolated frequency conversion and speed regulation, utilizing three-phase

Get Price

The difference between industrial frequency inverter and high frequency

Because there is a power frequency transformer between the inverter power supply and the load, the inverter operates stably, reliably, has strong overload capacity and impact

Get Price

High-Frequency Inverter: How They Work and Why They Matter

High-frequency inverters generally use Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) or Insulated Gate Bipolar Transistors (IGBTs). These semiconductor switches

Get Price

A High Frequency Variable Load Inverter Architecture

This thesis presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter architecture (referred to as HFVLI) that can directly drive

Get Price

Harmonic Overload: Impacts Of High-Frequency

During the CIGRE Grid of the Future symposium and workshop, harmonics were recognized as a critical focus in modern electrical systems, where high

Get Price

A High Frequency Inverter for Variable Load Operation

Inverters operating at high frequency (HF, 3-30MHz) are important to numerous industrial and commercial applications such as induction heating, plasma generatio

Get Price

Surge vs. Efficiency: Choosing Between Low and High

One of the most critical architectural decisions an engineer faces is the choice between a line-frequency (or low-frequency) and a high-frequency design. This choice has

Get Price

Frequency inverters

A frequency inverter is a technical device that generates a different AC voltage from the incoming AC voltage. Frequency converters are used, for example, to control motor speeds (e.g. of an

Get Price

Blast furnace blower process and frequency inverter transformation_High

Therefore, at present, there are very few cases of high voltage frequency inverter transformation of blast furnace blower, the main reason is that users have doubts about the reliability of high

Get Price

Medium frequency and high frequency DC inverter transformers:

Due to their different frequency characteristics, medium-frequency DC inverter transformers and high-frequency DC inverter transformers are suitable for industrial heating,

Get Price

High Frequency Inverter Board Assembly | Best Technology

What is high frequency inverter board? This guide covers its basics, how it works, function and application and differences from low-frequency ones.

Get Price

Inversion Methods Explained: High Frequency vs Low Frequency

Understand the difference between high frequency and low frequency inverters with this quick article.

Get Price

Demystifying High Frequency vs Low Frequency

The main difference between High-frequency and Transformer-based Low-Frequency Inverters/UPS is the frequency at which they operate.

Get Price

Understanding the Difference Between Frequency

Choosing between a frequency inverter and a high-frequency inverter depends on your specific needs—whether you''re looking for power

Get Price

Frequency Inverter Basic: Introduction, Functions and

Function of Frequency Inverter Speed Regulation Function: Frequency inverters can change the speed of the motor by adjusting the

Get Price

High Frequency Inverter for Industrial Applications

High frequency inverters play a critical role in modern industrial applications, converting DC power into high-frequency AC power for a wide range of machinery and equipment. These inverters

Get Price

Understanding the Difference Between Frequency Inverters and High

Choosing between a frequency inverter and a high-frequency inverter depends on your specific needs—whether you''re looking for power efficiency, space saving, or suitability

Get Price

High Vs Low Frequency Inverters/UPS Comparison

Let us compare High Vs Low-Frequency Inverters/UPS Comparison. Two kinds of commonly used Inverters/UPS; High Frequency and Low

Get Price

Research on High-Frequency Isolated NPC Three

To tackle these challenges, this paper presents a three-stage topology for high-frequency isolated frequency conversion and speed

Get Price

Power Frequency Inverter vs High-Frequency Inverter

High-frequency inverters deploy high-frequency switching systems to chop direct current power at high frequency with high-frequency tubes like MOSFETs. They then shift the

Get Price

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

One of the most critical architectural decisions an engineer faces is the choice between a line-frequency (or low-frequency) and a high-frequency design. This choice has

Get Price

High-Frequency Inverter: How They Work and Why

High-frequency inverters generally use Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) or Insulated Gate Bipolar

Get Price

High Frequency Inverter Circuit

This type of inverter is most commonly used for certain industrial or commercial applications where power must be generated at a high

Get Price

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

ABSTRACT The High-Frequency Inverter is mainly used today in uninterruptible power supply systems, AC motor drives, induction heating and renewable energy source systems. The

Get Price

The difference between industrial frequency inverter and high

Because there is a power frequency transformer between the inverter power supply and the load, the inverter operates stably, reliably, has strong overload capacity and impact

Get Price

More related information

-

Is the grid-connected inverter industrial frequency or high frequency

Is the grid-connected inverter industrial frequency or high frequency

-

Conversion efficiency of industrial frequency inverter and high frequency inverter

Conversion efficiency of industrial frequency inverter and high frequency inverter

-

High frequency inverter parallel operation

High frequency inverter parallel operation

-

Swedish industrial frequency off-grid inverter company

Swedish industrial frequency off-grid inverter company

-

Inverter high frequency hybrid

Inverter high frequency hybrid

-

Bahamas high frequency inverter installation

Bahamas high frequency inverter installation

-

High frequency inverter to 24v

High frequency inverter to 24v

-

What is the price of high frequency inverter

What is the price of high frequency inverter

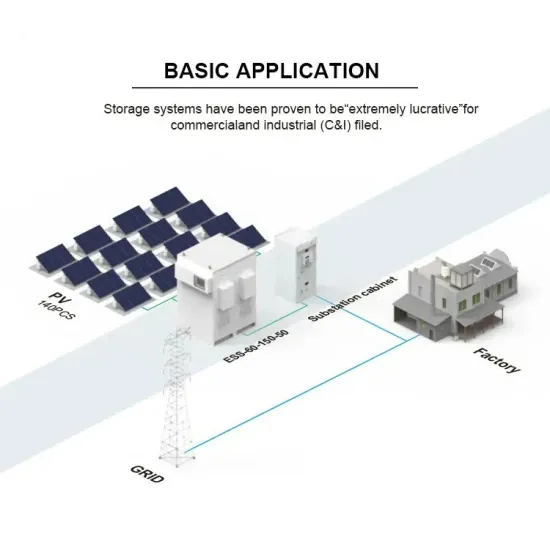

Commercial & Industrial Solar Storage Market Growth

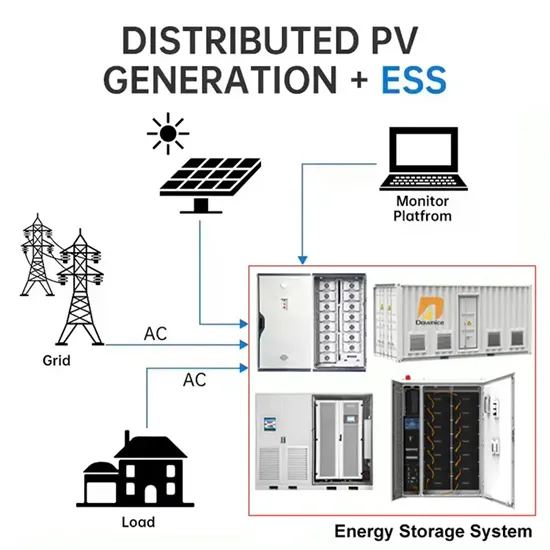

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

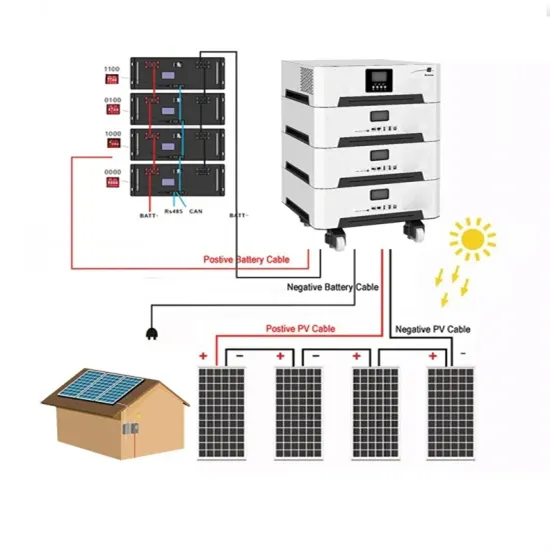

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.