Protection and Monitoring Functions of Inverters:

In modern energy systems, inverters play a crucial role as key components that convert DC power to AC power, providing stable and reliable

Get Price

The Only Inverter Size Chart You''ll Ever Need

We created a comprehensive inverter size chart to help you select the correct inverter to power your appliances. The need for an inverter size chart first became apparent

Get Price

Inverter Specifications and Data Sheet

The ability of an inverter to accurately convert DC to AC, operate within specified voltage and current limits, and incorporate safety and control features such as MPPT, transfer switches,

Get Price

12 Volt DC Power Inverter: In-Depth Learning and Buying Guide

Recommended Power Range: 1000W - 2000W inverters, depending on the total power draw of essential devices. By choosing the right 12V inverter for your specific needs,

Get Price

Introduction to inverters: structure, operating

Discover the basics of inverters - their structure, operating principles, and functions. Explore Junchipower''s expertise in this informative

Get Price

Understanding inverter voltage

While a 12V inverter is suitable for smaller applications, a 24V inverter is often preferred for larger systems. The 24V configuration offers

Get Price

12V vs 24V Inverter: What''s The Difference & Which is Better

Torn between 12V and 24V inverters? Discover the key differences in efficiency, cost, and power capacity to determine which is better for your energy needs.

Get Price

Understanding inverter voltage

While a 12V inverter is suitable for smaller applications, a 24V inverter is often preferred for larger systems. The 24V configuration offers advantages in terms of efficiency

Get Price

What is a Battery Inverter? A Comprehensive Overview

What''s a battery inverter? Battery inverters convert energy for your devices. Learn their key features and benefits to improve your energy use.

Get Price

DC-to-AC Converters (Inverters): Design, Working &

These are used in numerous applications, including PV systems, battery storage systems, traction drives, variable speed drives, etc. Converting

Get Price

What is a Power Inverter? | Power Home

A power inverter is a key piece of electrical equipment used to convert DC power to AC power. It plays an important role in a variety of fields

Get Price

When choosing an inverter, what voltage ratings

The operating voltage range is the range of voltages within which an inverter can continuously function without damage. Operating voltage range 5 ensures

Get Price

Understanding Basics Of An Inverter Circuit: How It

In converting DC (direct current) to AC (alternating current) to power electronic devices in your home, inverters cannot perform their role without a functioning

Get Price

12V Inverter vs 24V Inverter — What Is The

This article will explore the differences between 12v inverter vs 24v inverter, considering factors such as energy loss, battery requirements, and

Get Price

Understanding inverter frequency – effects and adjustments

In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per second. This inverter frequency is

Get Price

What Size Inverter Do I Need? | REDARC

WHAT DOES AN INVERTER DO? An inverter converts 12V DC battery power into 240V AC power. This allows you to run standard household appliances and electronics while travelling

Get Price

When choosing an inverter, what voltage ratings should you pay

The operating voltage range is the range of voltages within which an inverter can continuously function without damage. Operating voltage range 5 ensures your inverter runs smoothly

Get Price

How To Read And Interpret An Inverter Specification

Inverters generally have an input voltage of 12V, 24V, or 48V. The inverter selected must match the power source, such as batteries or solar panels. Solar and EV systems usually use higher

Get Price

A comprehensive guide to inverter voltage

For 12V inverters, the inverter start voltage is typically between 10V and 12V. This threshold ensures that the inverter can reliably start operation without overloading the

Get Price

12 Volt DC Power Inverter: In-Depth Learning and

Recommended Power Range: 1000W - 2000W inverters, depending on the total power draw of essential devices. By choosing the right

Get Price

How to Read Solar Inverter Specifications

The AC output voltage range is all about the ideal range of voltages that the inverter can produce for connecting to the main grid. It is crucial to maintain the output voltage

Get Price

Best Inverter For Home

An inverter is an important part of the Indian household. It is much easier to connect and use than a generator and ensures that you have power back-up in case your home experiences

Get Price

Understanding inverter frequency – effects and

In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per

Get Price

What Does an Inverter Do, and How Does It Work | Renogy US

An inverter converts DC power from batteries or solar panels into AC power for household appliances. It''s essential for off-grid systems, RVs, and backup power, enabling the use of

Get Price

A comprehensive guide to inverter voltage

For 12V inverters, the inverter start voltage is typically between 10V and 12V. This threshold ensures that the inverter can reliably start

Get Price

5 Things You Need to Know About 12V Inverters | L&T-SuFin

We have compiled a list of five important things you need to know about 12v inverters to make an informed decision. We''ll cover the types and safety tips of the products

Get Price

Buy a 12v inverter from the wide range of inverters at Repco

Use an inverter and turn that 12 volt power into powering any appliance. Repco''s range of inverters are compact and with leading brands at the best prices.

Get Price

How To Read And Interpret An Inverter Specification

Inverters generally have an input voltage of 12V, 24V, or 48V. The inverter selected must match the power source, such as batteries or solar panels.

Get Price

Inverter Cable Size Calculator & Formula Online Calculator Ultra

For an inverter with 1200W power, a system voltage of 12V, a cable length of 20 feet, and a maximum voltage drop of 3%, the required cable size would be approximately AWG 4.

Get Price

What is best 12v or 24v Inverter

Remote control: When the inverter is placed at a high place, the remote control can help users easily operate the inverter. TYCORUN''s inverters use radio

Get Price

6 FAQs about [What is the controllable range of a 12V inverter ]

What voltage is a 12V inverter?

Inverters come in various configurations, each designed for specific power systems. Common rated input voltages include 12V, 24V, and 48V. The choice depends on the application, the size of the power system, and the available power source. A 12V inverter is commonly used for smaller applications, such as in vehicles or small off-grid setups.

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

What is a safe voltage for a 12V inverter?

For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate fluctuations in the power source and protect the inverter from potential damage. What happens if voltage is too high for inverter?

What are inverter voltage ratings?

Inverter voltage ratings are critical to ensure compatibility with your solar system and battery setup. Pay attention to these numbers. When selecting an inverter, understanding voltage ratings ensures proper system compatibility, efficiency, and longevity. Key ratings to focus on include rated voltage, maximum input voltage, and others.

What is the cut off voltage on a 12V inverter?

For a 12V inverter, the cut-off inverter voltage is often set around 9.5VDC. Dropping below this threshold triggers a shut-off mechanism to preserve the battery's health and longevity. How do you check the voltage on an inverter?

What is a maximum input voltage in a solar inverter?

The maximum input voltage defines the highest voltage the inverter can safely accept without causing damage. [Maximum input voltage] (Maximum input voltage in solar inverters) 2 indicates the upper voltage limit an inverter can handle. It’s crucial for ensuring long-term durability.

More related information

-

What is the maximum power of a 12v high power inverter

What is the maximum power of a 12v high power inverter

-

What is the output voltage of a 12v inverter 4kw

What is the output voltage of a 12v inverter 4kw

-

What size inverter is suitable for 12v 40A

What size inverter is suitable for 12v 40A

-

What size inverter should I use with a 12V 50A lithium battery

What size inverter should I use with a 12V 50A lithium battery

-

What is C12 in a 12v inverter

What is C12 in a 12v inverter

-

What size inverter should I use for a 12v 180a battery

What size inverter should I use for a 12v 180a battery

-

What is the price of a regular inverter in Jamaica

What is the price of a regular inverter in Jamaica

-

3 7 Boost 12v Inverter

3 7 Boost 12v Inverter

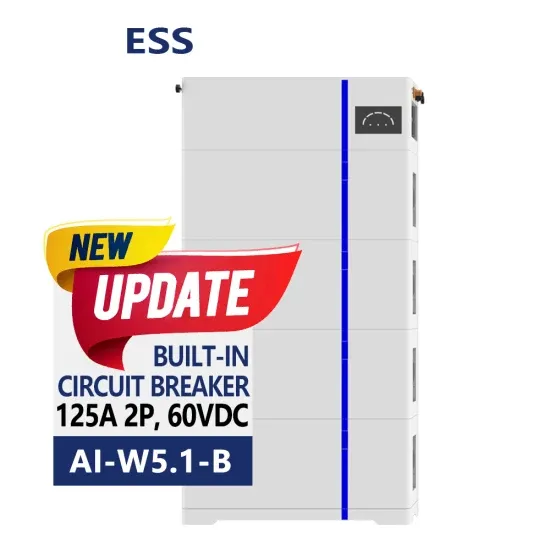

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.