Monocrystalline Silicon

Monocrystalline silicon, also known as single-crystal silicon, is a type of silicon that has a continuous crystal lattice structure. This unique structure makes it an ideal material for solar

Get Price

Monocrystalline vs. Polycrystalline Solar Panels: Key Differences

Definition: Monocrystalline solar panels are made from a single continuous crystal structure, offering high efficiency in converting sunlight into electricity. Manufacturing: They are produced

Get Price

What Is Monocrystalline Silicon and Why Is It Dominant in Solar Panels?

Silicon is a semiconductor, a material that can conduct electricity under certain conditions, which makes it ideal for solar panels that convert sunlight into electricity. The

Get Price

Monocrystalline silicon

It consists of silicon in which the crystal lattice of the entire solid is continuous, unbroken to its edges, and free of any grain boundaries (i.e. a single crystal).

Get Price

What kind of silicon is used in solar photovoltaic panels?

Monocrystalline silicon is widely recognized as the gold standard in the solar photovoltaic panel industry. This type of silicon is produced from a single, continuous crystal

Get Price

The Science Behind Monocrystalline Solar Panels

Monocrystalline solar panels are made from a single crystal of silicon, which provides a uniform structure that allows electrons to move more

Get Price

What is Crystalline Silicon Solar Cell?

Solar panels known as polycrystalline or multi-crystalline include many silicon crystals within a single PV cell. The wafers of polycrystalline solar

Get Price

Comprehensive Guide to Monocrystalline Solar Panel

The efficiency of monocrystalline solar panels is due to the purity of the silicon used in their manufacture. Monocrystalline silicon has a more uniform structure than other silicon

Get Price

What is Monocrystalline Solar Panel? Advantages and

The main difference between monocrystalline and polycrystalline solar cells in Hindi is the type of silicon solar cell they use; monocrystalline

Get Price

Crystalline Silicon Solar Cell

Crystalline silicon solar cells are defined as a type of solar cell that has been utilized for photovoltaic systems, known for their longevity and efficiency, and are categorized into

Get Price

Types of Solar Panels: Monocrystalline vs

Monocrystalline solar panels are made from a single crystal structure, typically silicon, which allows for higher efficiency. Polycrystalline

Get Price

How to Distinguish Mono, Poly and Amorphous Silicon Solar Panels?

Distinguishing between monocrystalline silicon, polycrystalline silicon, and amorphous silicon solar panels can be done by examining their physical appearance and

Get Price

Crystalline Silicon Solar Cell

The device structure of a silicon solar cell is based on the concept of a p-n junction, for which dopant atoms such as phosphorus and boron are introduced into intrinsic silicon for preparing

Get Price

Mono-crystalline Solar Cells

The silicon used to make mono-crystalline solar cells (also called single crystal cells) is cut from one large crystal. This means that the internal structure is highly ordered and it is easy for

Get Price

What Is a Monocrystalline Solar Panel? Definition,

The efficiency of a solar panel is a critical factor, as it determines how much sunlight is converted into electrical power. Monocrystalline solar

Get Price

The Anatomy of a Solar Cell: Constructing PV Panels Layer by

The cell''s unique structure, consisting of two distinct semiconductor layers – one positively charged (p-type) and one negatively charged (n-type) – creates an electric field at

Get Price

The Science Behind Sun-Powered Crystals

Monocrystalline solar cells are made from a single continuous crystal of silicon, meaning the silicon atoms are arranged in a perfect, uniform lattice. This ordered structure

Get Price

The Science Behind Monocrystalline Solar Panels

Monocrystalline silicon, often referred to as single-crystal silicon, is a material that consists of silicon atoms arranged in a continuous, unbroken crystal lattice. This uniform

Get Price

The Anatomy of a Solar Cell: Constructing PV Panels

The cell''s unique structure, consisting of two distinct semiconductor layers – one positively charged (p-type) and one negatively

Get Price

High-Efficiency Crystalline Photovoltaics | Photovoltaic Research

High-Efficiency Crystalline Photovoltaics NREL is working to increase cell efficiency and reduce manufacturing costs for the highest-efficiency photovoltaic (PV) devices involving

Get Price

Monocrystalline Silicon

This single crystal structure gives monocrystalline silicon solar panels a higher efficiency and a sleeker appearance compared to other types of solar panels. The process of

Get Price

What is a single crystal solar cell? | NenPower

At the core of solar energy technology, single crystal solar cells are distinguished by their uniform structure, which is created from a single crystal

Get Price

Monocrystalline vs. Polycrystalline: The Hidden Structure Behind

3 days ago· Monocrystalline Solar Panels Because the silicon in a monocrystalline cell is a single, perfect crystal, electrons have a clear, unobstructed path to travel. This lack of grain

Get Price

What Is Monocrystalline Silicon and Why Is It Dominant in Solar

Silicon is a semiconductor, a material that can conduct electricity under certain conditions, which makes it ideal for solar panels that convert sunlight into electricity. The

Get Price

Monocrystalline vs. Polycrystalline solar panels

Key takeaways Monocrystalline solar panels have black-colored solar cells made of a single silicon crystal and usually have a higher efficiency

Get Price

The Science Behind Monocrystalline Solar Panels

Monocrystalline silicon, often referred to as single-crystal silicon, is a material that consists of silicon atoms arranged in a continuous, unbroken

Get Price

What kind of silicon is used in solar photovoltaic panels?

Monocrystalline silicon is widely recognized as the gold standard in the solar photovoltaic panel industry. This type of silicon is produced from a

Get Price

Single Crystal Solar Panels vs. Polycrystalline & Thin-Film: Which

These panels use silicon grown from a single crystal structure, making them the efficiency champions of rooftop solar. But wait - does that mean they''re always the best choice? Grab

Get Price

More related information

-

Which is better single crystal silicon n-type or p-type photovoltaic panel

Which is better single crystal silicon n-type or p-type photovoltaic panel

-

Photovoltaic panel single crystal photoelectric conversion process

Photovoltaic panel single crystal photoelectric conversion process

-

Photovoltaic panel single crystal size

Photovoltaic panel single crystal size

-

What does 540w single crystal photovoltaic panel mean

What does 540w single crystal photovoltaic panel mean

-

Monocrystalline silicon solar panel price per watt

Monocrystalline silicon solar panel price per watt

-

Solar photovoltaic panel single block specifications

Solar photovoltaic panel single block specifications

-

Single crystal perc72 panel type components

Single crystal perc72 panel type components

-

Timor-Leste Silicon Solar Panel System

Timor-Leste Silicon Solar Panel System

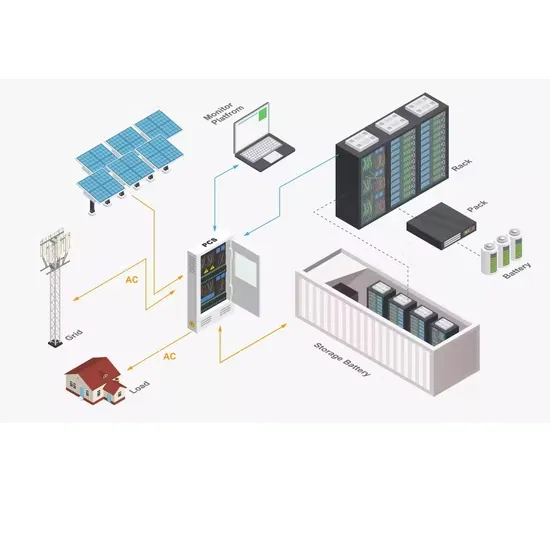

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

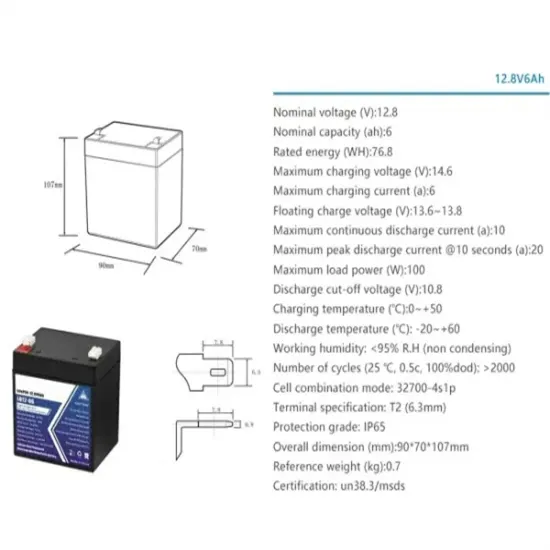

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.