Battery Safety Initiative

Battery Diagnostics and Prognostics Evaluate the health of a battery: early detection (prognostics), diagnostics, and intervention Battery Management System (BMS) Cybersecurity

Get Price

Safety Standards for Advanced Battery Management Systems

The evolution of Battery Management System (BMS) safety standards has been closely tied to the rapid advancement of battery technology, particularly in the automotive and

Get Price

Functional safety requirements for BMS in electric cars (ISO 26262)

During the three-day long event with presentations from some of the most important thought leaders in battery research, Ole talks in detail about the functional safety requirements of

Get Price

(PDF) Functional Safety BMS Design Methodology for

The increasing use of lithium batteries and the necessary integration of battery management systems (BMS) has led international

Get Price

AN215 Functional Safety Concept for BMS Solution:

This application note discusses the recommended safety measures to be implemented in the BMS architecture based on an MPS battery monitor and protector (BM&P) in combination with

Get Price

Functional Safety Design and ISO26262 Compliance for

The BMS system software will take care of the battery state of health (SOH), state of charge (SOC) and overall safety of the battery pack and thus the vehicle. To ensure the safety of

Get Price

IEEE Publishes BMS Design Standards for Stationary Systems

What''s next for battery manufacturers and utilities? IEEE''s completion of this standard is a significant development for the battery industry, providing comprehensive BMS

Get Price

IS 17387 : 2020: General Safety and Performance Requirements of Battery

IS 17387 : 2020: General Safety and Performance Requirements of Battery Management Systems by Bureau of Indian Standards Publication date 2020-8-25 Topics data.gov , standardsbis ,

Get Price

Ensuring Battery Safety and Performance: IS 17387:2020 and the

IS 17387:2020 specifies key safety and performance criteria for BMS, aiming to mitigate potential risks such as overcharging, overheating, and system failures. The standard emphasizes the

Get Price

Functional and Safety Guide for Battery Management

The test aims to confirm that BMS autotests detect the introduction of corrupted data within safety-related software and configuration files and that the mode management function places the

Get Price

Critical review and functional safety of a battery management

This paper analyzed the details of BMS for electric transportation and large-scale energy storage systems, particularly in areas concerned with hazardous environment. The analysis covers the

Get Price

Safety Standards For Battery Management (BMS) In Electric Vehicle

In this article, I will discuss the types of safety standards for battery management systems (BMS) in electric vehicles and how they affect.

Get Price

How Do Battery Management Systems Help Meet Safety

It enforces UL 1973 and UN 38.3 standards through cell balancing, overcharge/discharge prevention, and thermal runaway mitigation. Advanced BMS designs

Get Price

ISO 26262 Functional Safety Compliant BMS

Legal Consequences 26262 describes the SOTA in relation to functional safety during the lifecycle of safety-related systems comprised of E/E and software elements in vehicles that

Get Price

Why does the industry need battery safety management system

In the authors'' view, these BMS have limited capability to maintain battery safety. The BMS is designed to provide longer, stable battery life and efficient operation. It can help in

Get Price

IEC publishes standard on battery safety and performance

IEC 62619 also addresses functional safety for battery management systems (BMS) based on IEC 61508. It includes testing requirements for voltage and current controls to

Get Price

IEC publishes standard on battery safety and

IEC 62619 also addresses functional safety for battery management systems (BMS) based on IEC 61508. It includes testing

Get Price

Key Safety Standards for Automotive & Industrial BMS

Explore key safety standards for Battery Management Systems (BMS) in automotive & industrial applications, ensuring safe, reliable high-voltage operations.

Get Price

Global Standards Certifications for BESS

he Global Standards Certifications for BESS container based solutions is significant. As Battery Energy Storage Systems become critical to

Get Price

Key Safety Standards for Automotive and Industrial Battery

Key Safety Standards for Automotive and Industrial BMS Several safety standards govern the design, implementation, and operation of BMS in automotive and industrial

Get Price

2686-2024

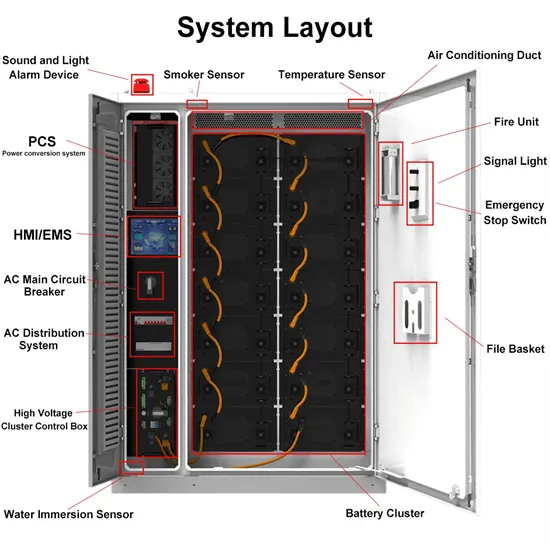

Scope: This recommended practice includes information on the design, configuration, and interoperability of battery management systems (BMSs) in stationary

Get Price

How Do Battery Management Systems Help Meet Safety Standards?

It enforces UL 1973 and UN 38.3 standards through cell balancing, overcharge/discharge prevention, and thermal runaway mitigation. Advanced BMS designs

Get Price

Safety Standards For Battery Management (BMS) In

In this article, I will discuss the types of safety standards for battery management systems (BMS) in electric vehicles and how they affect.

Get Price

Functional safety requirements for BMS in electric

During the three-day long event with presentations from some of the most important thought leaders in battery research, Ole talks in detail about the

Get Price

Understanding Electric Vehicle Battery Safety Standards

Battery Management System (BMS): Constantly monitors the battery''s health, temperature, and voltage, preventing overheating or

Get Price

BFE Family Functional Safety Manual

Functional Safety in Battery Management Systems Featuring Renesas Battery Front Ends This manual covers several recommended usage and mechanisms of Renesas

Get Price

Regulatory Push: How Standards Are Shaping BMS

EV batteries are very critical & expensive components and account for up to 30-40% of an EV''s overall cost. Hence it presents an unprecedented emphasis on the

Get Price

6 FAQs about [Battery BMS system safety standards]

What are functional safety standards for battery management systems (BMS)?

Functional safety standards ensure that safety-related functionality in Battery Management Systems (BMS) is maintained throughout its lifecycle, mitigating risks that could compromise the system’s reliability and safety. ISO 26262 is a key standard for automotive functional safety, focusing on electrical and electronic systems, including BMS.

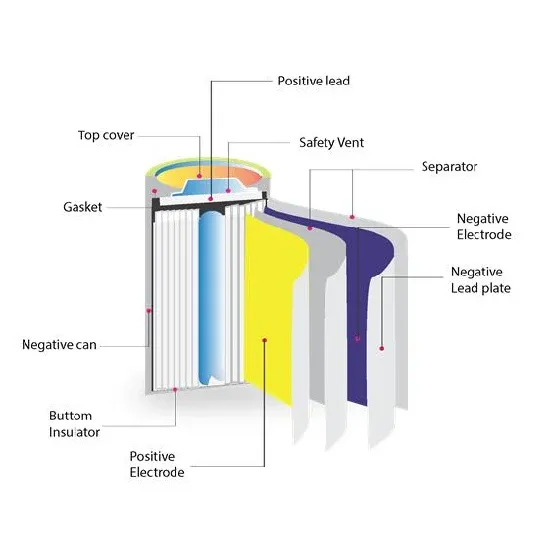

What is a battery management system (BMS)?

Battery Management Systems (BMS) are at the heart of electric vehicle (EV) safety, ensuring the efficient and reliable operation of lithium-ion batteries. As batteries become more powerful and complex, maintaining their safety, performance, and longevity is critical.

What are battery-specific standards?

Battery-specific standards address the design, testing, and safety requirements of battery systems, which directly influence the functionality and safety of the BMS. UN 38.3 governs the transport of lithium batteries and mandates specific safety tests to ensure safe handling during shipping.

What are the safety requirements for a BMS?

Safety requirements for the BMS are also defined by these standards, encompassing aspects such as fault tolerance, fail-safe operation, and risk mitigation strategies to ensure safe system functionality.

Why do we need BMS standards?

The integration of these standards in the design and operation of BMS helps to protect sensitive vehicle and battery data, ensuring that external threats do not disrupt the system’s safety functions, potentially leading to dangerous outcomes. 06. Environmental and Reliability Standards

Why is a battery management system important?

High-voltage batteries used in electrification applications are safety-critical & expensive components. Hence, it is vital to have an intelligent battery management system (BMS) to ensure safe and reliable operations.

More related information

-

BMS battery management safety

BMS battery management safety

-

Cambodia lithium battery BMS

Cambodia lithium battery BMS

-

Benin New Energy Lithium Battery BMS Standard

Benin New Energy Lithium Battery BMS Standard

-

Middle East BMS lithium battery project

Middle East BMS lithium battery project

-

The world s top production BMS battery management system

The world s top production BMS battery management system

-

Rwanda outdoor battery cabinet bms price

Rwanda outdoor battery cabinet bms price

-

Bms lithium battery customization

Bms lithium battery customization

-

Vaduz Huijue 92ah battery bms

Vaduz Huijue 92ah battery bms

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.