Protective equipotential bonding in solar systems – standards

Protective equipotential bonding ensures greater safety and efficiency in solar systems. But what exactly does it mean, and which laws and standards must you comply with

Get Price

Ground-mounted photovoltaic power plants

Technical areas addressed are those that largely distinguish PV power plants from smaller, more conventional installations, including ground mounted array configurations, cable routing

Get Price

Equipotential earth bonding is a critical aspect of solar PV system

Proper equipotential bonding ensures that all metallic parts of the PV system, including module frames and mounting structures, are at the same electrical potential.

Get Price

Lightning and surge protection for photovoltaic (PV)

Damage is not only limited to potentially high repair costs but also loss of service and important revenue for Solar Power plants. Protection for

Get Price

Lightning protection techniques for roof-top PV systems

Finally, it is conceivable that lightning may strike the solar panels directly, harming the machinery, rendering it difficult to produce power, and seriously igniting flames [43].

Get Price

Equipotential earth bonding is a critical aspect of solar

Proper equipotential bonding ensures that all metallic parts of the PV system, including module frames and mounting structures, are at the same

Get Price

Equipotential Bonding and Lightning Protection

It is important to ensure that the power input and output are designed with different cross-sections depending on the function. We recommend a minimum cross-section of ≥ 6 mm2 copper or ≥

Get Price

Equipotential Bonding of Photovoltaic Systems

The paper discusses the distinctions between Class I and Class II PV equipment, highlighting the implications for grounding and bonding based on the type of insulation employed.

Get Price

Equipotential bonding for photovoltaic systems | OBO

The necessary lightning protection equipotential bonding achieved in this way connects all the metallic and electrically conductive components of the

Get Price

WP018-E-0615_PV_rooftop

Earthing of PV systems PV modules are typically fixed on metal mounting systems. The live PV components on the d.c. side feature double or reinforced insulation (comparable to the

Get Price

How to ensure you have a compliant PV installation

Recent data from audits of solar installations have found that the number one defect for solar installations is inadequately earthed solar panels. There are two main methods used for

Get Price

Solar Panel Connectors and Cables

Solar Panel Connectors and Cables How to Use MC4 Connectors and MC4 Extension Cables NOTE: There are multiple types of interlocking PV connectors. This article addresses MC4

Get Price

Earthing the Array

, Earthing the Array - Practically, Solar PV Forum | Solar Panels Forum, ElectriciansForums Est.2006 | Free Electrical Advice Forum and page_number.

Get Price

Equipotential bonding

Insulated protective conductors for earthing and equipotential bonding must be indicated as protective conductors. NB: in the case of equipotential bonding of the lightning protection

Get Price

Does a solar energy system need to be earthed?

The solar panels themselves are double insulated, meaning they do not need additional bonding. The NEN 1010 standard requires equipotential bonding (earthing) of a PV system.

Get Price

SPD for photovoltaic applications

The first safeguard to put in place is a medium (conductor) that ensures equipotential bonding between all the conductive parts of a PV installation. The aim is to bond

Get Price

Equipotential bonding

Thanks to special "equipotential bonding plates" in our panel clamps, the frames of the solar panels are also connected to rest of the system as soon as the clamps are properly tightened.

Get Price

Grounding and equipotential bonding

When safely installing the solar power plant, a distinction must be made between grounding and equalizing the plant. The plant must be connected to earth for the dissipation of

Get Price

Solar System Continuity Test: How to easily test your earthing.

After we finished our work on the roof and connected all solar rails to ground potential, it is time to check on the results and do the ''Continuity Test''.

Get Price

solar power plant earthing

Fig. 1: Earthing in Solar Power Plant How to calculate the number of earthing pit in solar plant earthing: Calculating the number of earthing pits

Get Price

Protecting PV installations against surges | DEHN

A failure of the PV system has expensive consequences: There is no electricity generation for personal use or income from energy infeed, and additional

Get Price

Photovoltaic panels equipotential

Photovoltaic (PV) systems – Requirements for testing, It is a revision of SS 601 : 2014 "Code of practice for maintenance of grid-tied solar photovoltaic (PV) power supply system". This

Get Price

Equipotential bonding for photovoltaic systems | OBO

The necessary lightning protection equipotential bonding achieved in this way connects all the metallic and electrically conductive components of the system, including the earthing system,

Get Price

maasstudiebegeleiding

If components are used in the PV system that require equipotential bonding (e.g., mounting racks, module frames), these must be connected to a central equipotential panel provided for this

Get Price

SAFETY OF PHOTOVOLTAIC MODULES – AN

To address the latter Working Group 2 (WG2) of the Technical Committee for Solar Photovoltaic Energy Systems (TC 82) of the International

Get Price

Surge Protection for Photovoltaic Systems

Photovoltaic (PV) System: The total components and subsystem that, in combination, convert solar energy into electric energy for connection to

Get Price

More related information

-

Moldova solar panels photovoltaic panels

Moldova solar panels photovoltaic panels

-

Photovoltaic solar panels wholesale in Cambodia

Photovoltaic solar panels wholesale in Cambodia

-

Does Ethiopia have solar photovoltaic panels

Does Ethiopia have solar photovoltaic panels

-

Solar photovoltaic panels for Ugandan homes

Solar photovoltaic panels for Ugandan homes

-

One hundred megawatt solar photovoltaic panels

One hundred megawatt solar photovoltaic panels

-

German photovoltaic conductive solar panels

German photovoltaic conductive solar panels

-

Solar panels behind double-glass photovoltaic panels

Solar panels behind double-glass photovoltaic panels

-

3GW of solar photovoltaic panels

3GW of solar photovoltaic panels

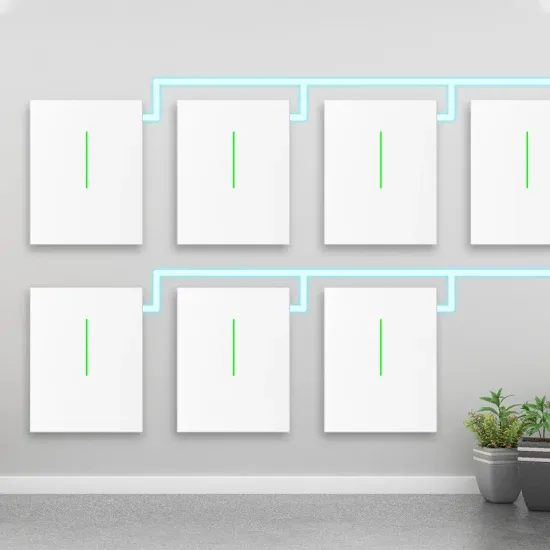

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

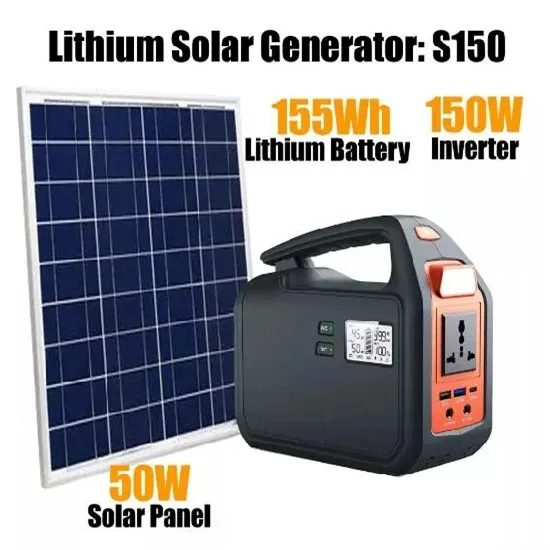

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.