Cell Contacting System-CCS

The necessary voltage and temperature sensors are already fited into the systems. In addition, the monitoring electronics (CSC) itself can also be integrated. Both approved and newly

Get Price

Reference Board: Cell Supervisory Circuit for Electric

By monitoring cell voltage, temperature, and sometimes current, the CSC ensures safe and efficient operation of the battery pack. Working as

Get Price

CSC

The HVX.csc (Cell Sensor Circuit) monitors the individual cells of the battery through the measurement of voltage, temperature and SOC. Every HVX.csc is

Get Price

Cell Contact System Assembly for Lithium-Ion

A cell contact system (CCS) module is the cover of the lithium-ion battery pack of EVs. A CCS module comprises a flexible PCBA module, black

Get Price

Master and Slave BMS

Battery state algorithms were programmed to calculate the State of charge, State of health, and power capability. In other words, keep the battery

Get Price

CSC City Slicker Electric Motorcycle Battery Upgrade (With

CSC City Slicker Battery Upgrade. The cells are new, have never been cycled, and are in excellent health. The downsides to this upgrade are loss of battery dash info, and

Get Price

HVBMS Cell Monitoring Unit (CMU) | NXP

The CMU role is to perform with high accuracy voltage and temperature measurements of each individual cell within the battery pack and to

Get Price

A Complete Guide to Understanding Battery Packs

Battery Pack Finally, the battery pack is the top-tier component incorporating multiple battery modules. It''s the ultimate package, ready to

Get Price

MSD function and selection of power battery system

The beginning of the MSD in the Power Battery System Pack gradually becomes standard from optional, this process is not too long, in

Get Price

What is MSD in battery pack?

Battery technology has come a long way in the past few years, and with the rise of electric vehicles and portable electronic devices, understanding the

Get Price

Master and Slave BMS

Battery state algorithms were programmed to calculate the State of charge, State of health, and power capability. In other words, keep the battery operating in the defined safety

Get Price

BMW iX Xdrive40 75kWh battery teardown

It is nice to see this is a serviceable battery pack (you can replace modules) which should give the car a better resale value / lower depreciation.

Get Price

Inside an Industrial Battery Pack: Key Components

Battery packs are the backbone of modern electrification. From electric vehicles (EVs) to large scale renewable energy storage systems, battery packs deliver efficiencies, reliability, and

Get Price

BMS and KEMET METCOM Inductors

When the number of battery cells is small, the Battery Management Unit (BMU) and Cell Supervisory Circuit (CSC) are placed on the same PCB.

Get Price

STW.csc Cell Sensor Circuit

The STW.csc (Cell Sensor Circuit) monitors the individual cells of the battery through the measurement of voltage, temperature and SOC. Every STW.csc is equipped with a passive

Get Price

The cell contacting system as an important

As an experienced automation expert in the e-mobility sector, AKE technologies has developed innovative processes for the automated production of cell

Get Price

STW.csc Cell Sensor Circuit

The STW.csc (Cell Sensor Circuit) monitors the individual cells of the battery through the measurement of voltage, temperature and SOC. Every STW.csc

Get Price

什么是电池包CCS集成母排?

图 CATL在2019年CES展会期间展出的方形模组Busbar设计,来源:知化汽车 传统线束母排在连接电池包时每一根线束到达一个电极,需要多根线束配合动力

Get Price

Battery management system and energy storage power station

Some embodiments relate to battery management technologies, and disclose a battery management system and an energy storage power station. The battery management system

Get Price

High Voltage Cell Supervising Circuit (CSC)

High Voltage Cell Supervising Circuit (CSC) Measurement of voltage and balancing of each battery cell inside the battery pack; temperature sensing in various points inside battery pack.

Get Price

Cell Contact System Assembly for Lithium-Ion Batteries [12 Steps]

A cell contact system (CCS) module is the cover of the lithium-ion battery pack of EVs. A CCS module comprises a flexible PCBA module, black films, and nickel sheets.

Get Price

BMS and KEMET METCOM Inductors

When the number of battery cells is small, the Battery Management Unit (BMU) and Cell Supervisory Circuit (CSC) are placed on the same PCB. But when the number of battery

Get Price

What is the Use of the Manual Service Disconnect (MSD)?

The primary function of a battery pack is to provide a portable power source, enabling devices to operate independently. The capacity, voltage, and other parameters of a

Get Price

High Voltage Cell Supervising Circuit (CSC)

High Voltage Cell Supervising Measurement of voltage and temperature of each battery cell inside the battery pack.

Get Price

Cell Supervision Circuit | Enhance Battery Safety & Performance

Easily integrates with both automotive and stationary battery chemistries, featuring a comprehensive cell module controller and cell supervision circuit (CSC) for seamless operation.

Get Price

LOW-VOLTAGE BATTERY PACK CONNECTOR

BATTERY PACK EXTERNAL COMMUNICATION INTERFACE The battery pack external communication interface is for the battery management unit (BMU) to communicate with

Get Price

CSC

The HVX.csc (Cell Sensor Circuit) monitors the individual cells of the battery through the measurement of voltage, temperature and SOC. Every HVX.csc is equipped with a passive

Get Price

Reference Board: Cell Supervisory Circuit for Electric Race Cars

By monitoring cell voltage, temperature, and sometimes current, the CSC ensures safe and efficient operation of the battery pack. Working as an intermediary system, the CSC

Get Price

APC Smart-UPS RT 192V Battery Pack

APC NetShelter Open Frame Rack, 2 Post, 45U, 12-24 Threaded Holes, Black APC Smart-UPS RT 19" Rail Kit for Smart-UPS RT 3/5/7.5/10kVA This

Get Price

6 FAQs about [What is CSC in pack battery ]

What is a STW CSC (cell sensor circuit)?

Talk to one of our experts. The STW.csc (Cell Sensor Circuit) monitors the individual cells of the battery through the measurement of voltage, temperature and SOC. Every STW.csc is equipped with a passive discharge path in order to balance out the battery cell charges. The cell sensor circuit communicates with the superordinate BMS.

What is a cell module controller & CSC?

Proactively addresses cell imbalances, overcharging, and overheating, safeguarding the battery system and extending its lifespan. Easily integrates with both automotive and stationary battery chemistries, featuring a comprehensive cell module controller and cell supervision circuit (CSC) for seamless operation.

What is a battery management unit (BMU) & cell supervisory circuit (CSC)?

When the number of battery cells is small, the Battery Management Unit (BMU) and Cell Supervisory Circuit (CSC) are placed on the same PCB. But when the number of battery cells that need to be managed increases, the BMU and CSC, need to be placed on different PCBs.

What is HVX CSC?

The HVX.csc (Cell Sensor Circuit) monitors the individual cells of the battery through the measurement of voltage, temperature and SOC. Every HVX.csc is equipped with a passive discharge path in order to balance out the battery cell charges. The cell sensor circuit communicates with the superordinate BMS.

What does CSC stand for?

Vitesco Technologies - High Voltage Cell Supervising Circuit (CSC) The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

What is HVX csc4 cell sensor?

The HVX.csc4 cell sensor circuit therefore provides high-precision voltage measurement paths, an over/undervoltage monitoring system and a cell temperature monitoring device. A forced shutdown is carried out in case of safety limit violations. Passive balancing with 160 mA is used as the standard for the balance of charges between the cells.

More related information

-

What is the charging voltage of a 7 2v lithium battery pack

What is the charging voltage of a 7 2v lithium battery pack

-

What is a battery pack BMS

What is a battery pack BMS

-

What is the charging voltage of a 74v lithium battery pack

What is the charging voltage of a 74v lithium battery pack

-

What is the normal voltage of Angola lithium battery pack

What is the normal voltage of Angola lithium battery pack

-

What power source can replace lithium battery pack

What power source can replace lithium battery pack

-

Saudi Arabia lithium iron phosphate battery pack

Saudi Arabia lithium iron phosphate battery pack

-

Canadian assembled lithium battery pack 60V

Canadian assembled lithium battery pack 60V

-

How many strings are there for a 72v 60ah lithium battery pack in the Netherlands

How many strings are there for a 72v 60ah lithium battery pack in the Netherlands

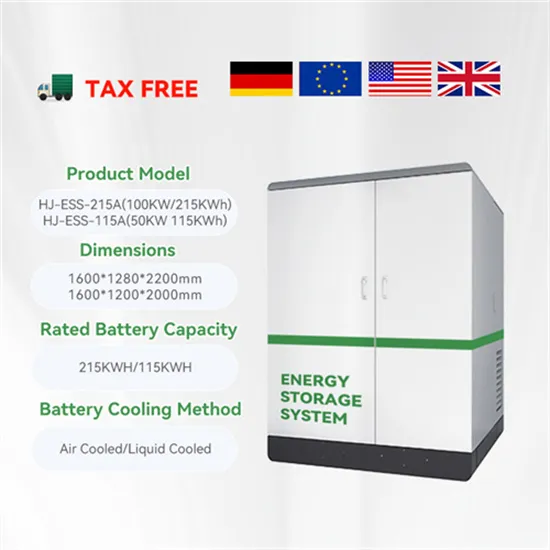

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

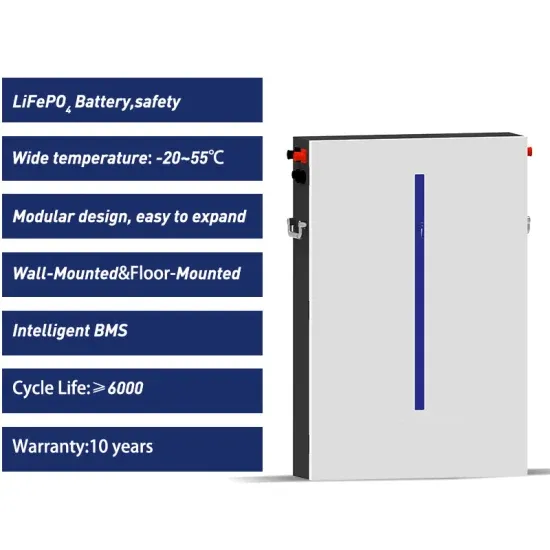

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.