Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get Price

Custom Lithium Battery Pack Manufacturing

In this comprehensive technical guide, I''ll share an in-depth look at our end-to-end custom lithium battery pack manufacturing process.

Get Price

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Price

Battery Manufacturing Basics from CATL''s Cell

Equipment plays a critical role in determining the performance and cost of lithium-ion batteries. Mirroring the three manufacturing stages,

Get Price

ETN News | Energy Storage News | Renewable

ETN news is the leading magazine which covers latest energy storage news, renewable energy news, latest hydrogen news and much more. This

Get Price

Lithium Battery Production Equipment Supplier

We specialize in providing battery pack solutions, including automatic battery sorting machines, and other lithium battery pack equipment.

Get Price

Top 10 lithium battery production equipment

This article introduces the top 10 lithium battery production equipment manufacturers in China,including company information and main

Get Price

Introduction to Production Equipment and Testing Methods for Lithium

This article provides an introduction to the production equipment and testing methods for lithium-ion battery packs, using 2025 industry data to guide your understanding.

Get Price

lithium-ion battery production lines

Our product portfolio starts after cell production and covers module and pack assembly for lithium-ion or sodium-ion batteries. We are developing, constructing and building customized

Get Price

The Manufacturing Process of Lithium Batteries

The lithium battery manufacturing industry is dominated by countries like China, Japan, and South Korea, which are major manufacturers and suppliers of

Get Price

Cell Manufacturing Equipment

Greatech Greatech designs and builds custom traditional and solidstate cell manufacturing equipment. Cylindrical, pouch and prismatic Cell inspection, modules and pack assembly

Get Price

What Is a Lithium Battery Pack Production Line?

These production lines integrate multiple stages of automation, precision engineering, and quality control to produce high-performance battery

Get Price

What Is a Lithium Battery Pack Production Line?

A lithium battery pack production line is a highly automated manufacturing setup designed to assemble and test lithium-ion battery packs.

Get Price

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Get Price

Optimizing Lithium-Ion Battery Pack Line Processes

Explore challenges and solutions in streamlining lithium-ion battery pack processes for efficient, customized, and automated production.

Get Price

Advanced lithium-ion battery process manufacturing equipment

Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and opportunities as

Get Price

Lithium Battery PACK Production Line Processes and

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Get Price

Battery Pack Manufacturing Process

The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are grouped into modules. This stage

Get Price

Battery Production | Lithium-ion & EV Battery Manufacturing Equipment

Nordson is globally renowned for providing high-quality and innovative battery manufacturing equipment, including 2K dispensing systems, bulk unloaders, slot dies, die lip adjustment

Get Price

lithium-ion battery production lines

Our product portfolio starts after cell production and covers module and pack assembly for lithium-ion or sodium-ion batteries. We are developing,

Get Price

Battery Production | Lithium-ion & EV Battery Manufacturing

Nordson is globally renowned for providing high-quality and innovative battery manufacturing equipment, including 2K dispensing systems, bulk unloaders, slot dies, die lip adjustment

Get Price

What Is a Lithium Battery Pack Production Line?

These production lines integrate multiple stages of automation, precision engineering, and quality control to produce high-performance battery packs for electric

Get Price

Opportunities in battery manufacturing equipment | McKinsey

Surging demand for battery cells gives rise to an opportunity for European machinery and equipment manufacturers to supply emerging gigafactories.

Get Price

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get Price

Lithium Battery PACK Production Line Processes and Equipment

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser

Get Price

Top 10 lithium battery production equipment companies in China

Today, I will talk about the suppliers of lithium battery production equipment for Top 10 lithium ion battery manufacturers. and then, I''d like to show how lithium battery packs are produced. Data

Get Price

Introduction to Production Equipment and Testing Methods for

This article provides an introduction to the production equipment and testing methods for lithium-ion battery packs, using 2025 industry data to guide your understanding.

Get Price

Top 10 Battery Assembly Line Equipment

Discover the top 10 battery assembly line factory manufacturer suppliers for 2025. Learn how to select the best equipment for your production

Get Price

Lithium Battery Module Pack Assembly Line

This advanced production line integrates a series of automated processes, including cell sorting, laser welding, module stacking, BMS installation, testing, and final pack assembly, tailored to

Get Price

Lithium-Ion Battery Manufacturing: Industrial View on

Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Get Price

More related information

-

Lithium battery pack assembly equipment

Lithium battery pack assembly equipment

-

Equipment required for lithium battery pack

Equipment required for lithium battery pack

-

Lithium battery pack production in Western Europe

Lithium battery pack production in Western Europe

-

West Africa pack lithium battery equipment

West Africa pack lithium battery equipment

-

Vertical lithium battery pack production

Vertical lithium battery pack production

-

High-power lithium battery pack production

High-power lithium battery pack production

-

El Salvador lithium battery pack source manufacturer

El Salvador lithium battery pack source manufacturer

-

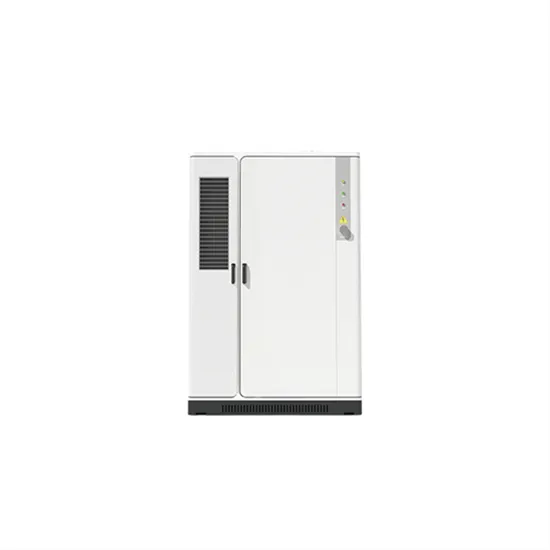

48v lithium battery pack wall mounted

48v lithium battery pack wall mounted

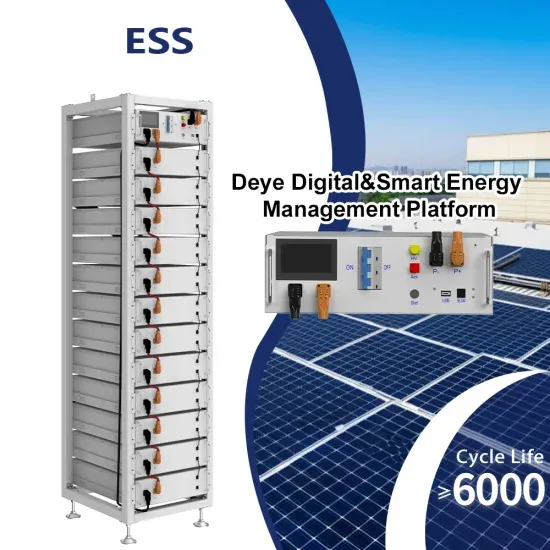

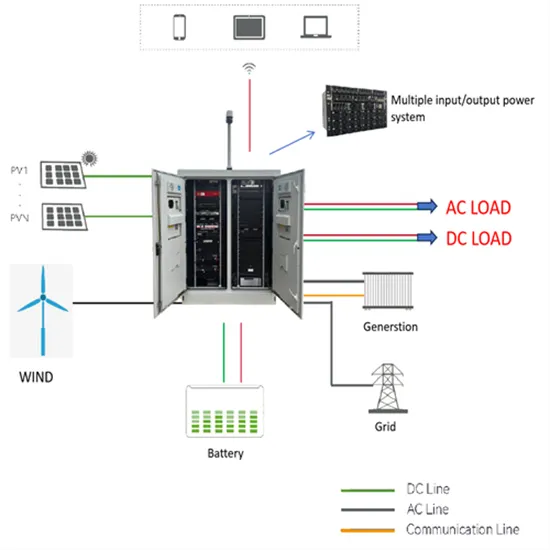

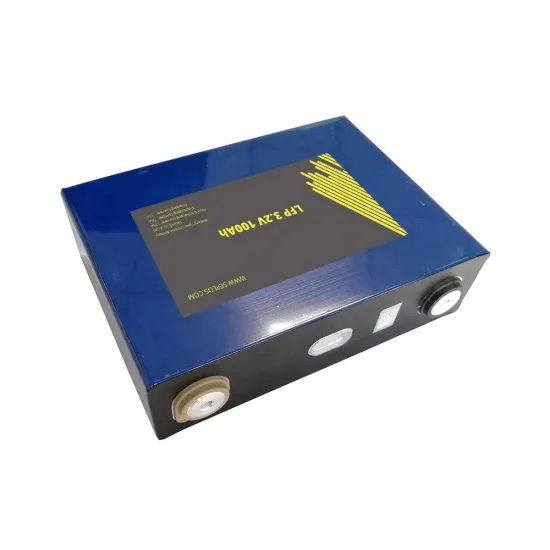

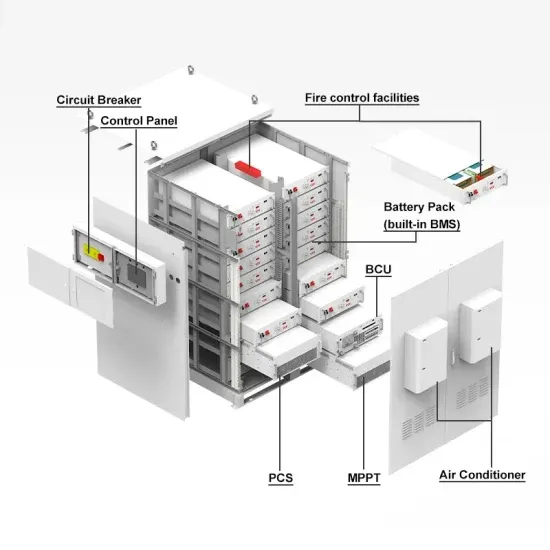

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.