Energy management of a battery-flywheel storage system used

Energy management of a battery-flywheel storage system used for regenerative braking recuperation of an Electric Vehicle. This article proposes an energy recuperation management

Get Price

A review of flywheel energy storage systems: state of the art

The ex-isting energy storage systems use various technologies, including hydro-electricity, batteries, supercapacitors, thermal storage, energy storage flywheels,[2] and others.

Get Price

Fault Ride Through and Intermittency Improvement of Renewable Energy

To test the effectiveness of the proposed control method for the flywheel energy storage in reducing excess energy in the HVDC link, symmetrical and asymmetrical low

Get Price

Flywheel Energy Storage Basics

The high energy density and low maintenance requirements make it an attractive energy storage option for spacecraft. Conclusion: Flywheel energy storage is a promising technology with

Get Price

Flywheel Energy Storage: A High-Efficiency Solution

Flywheel energy storage is an exciting solution for efficient and sustainable energy management. This innovative technology offers high

Get Price

36 Facts About Flywheel Energy Storage

What is Flywheel Energy Storage? Flywheel energy storage is a method of storing energy using a rotating mechanical device. This technology has been around for centuries but

Get Price

Optimization strategy for braking energy recovery of electric

Braking energy recovery (BER) notably extends the range of electric vehicles (EVs), yet the high power it generates can diminish battery life. This paper proposes an

Get Price

Optimization strategy for braking energy recovery of electric

Request PDF | On Dec 1, 2024, Zhou Zheng and others published Optimization strategy for braking energy recovery of electric vehicles based on flywheel/battery hybrid energy storage

Get Price

Optimisation of flywheel energy storage systems with geared

Flywheel energy storage systems with mechanical transmissions allow regenerative braking and power augmentation during acceleration in automotive vehicles. The development

Get Price

Flywheel turbine energy-storage brake method

A technology of energy storage braking and turbine, applied in control system, AC motor control, AC motor deceleration device, etc., can solve problems such as threats to system security.

Get Price

(PDF) Enhancing vehicular performance with flywheel energy storage

Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular

Get Price

High-precision stable control method for the rotor axis trajectory of

To address the suspension airgap fluctuations and vertical instability caused by rotor vibration in magnetically suspended flywheel energy storage systems (MS-FESS) under

Get Price

The Flywheel Energy Storage Method: Where Ancient Physics

Imagine a giant, high-tech version of your childhood spinning top – that''s essentially flywheel energy storage in a nutshell. This mechanical battery (who needs chemicals

Get Price

(PDF) Enhancing vehicular performance with flywheel

Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing

Get Price

On a Flywheel-Based Regenerative Braking System for

ABSTRACT This paper presents rgy recovery, storage and release system developed at the author''s laboratory. It can recover and store regenerative energy produced by braking a

Get Price

Flywheel energy storage

In order to speed up the rotor, a torque must be applied in the direction of rotation, to slow it down; the torque acts in the reverse direction. On one level, flywheel storage is very

Get Price

Flywheel Energy Storage

Of this, 17% is recoverable regenerative braking energy. However, the regenerative energy recovery in current urban rail systems is generally

Get Price

Dual-inertia flywheel energy storage system for

Introducing a novel adaptive capacity energy storage concept based on the Dual-Inertia Flywheel Energy Storage System for battery

Get Price

A comprehensive review of Flywheel Energy Storage System

Energy storage systems (ESSs) play a very important role in recent years. Flywheel is one of the oldest storage energy devices and it has several benefits. Flywheel Energy

Get Price

Optimization and control of battery-flywheel compound energy storage

A novel energy management method based on optimization and control of the battery-flywheel compound energy storage system is proposed for the braking energy

Get Price

The Future of Regenerative Braking in Flywheel Energy Storage

Explore the evolution of flywheel braking systems in energy storage, from early concepts to cutting-edge innovations. Discover future trends and applications.

Get Price

Optimization and control of battery-flywheel compound energy

A novel energy management method based on optimization and control of the battery-flywheel compound energy storage system is proposed for the braking energy

Get Price

Study of Flywheel Energy Storage in a Pure EV Powertrain in a

Even in current EV powertrains, the regeneration efficiency only reaches up to around 75%, which is much lower compared to the potential efficiency of flywheel-based

Get Price

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get Price

Exploring the Benefits and Limitations of Flywheel

This study aims to assess the feasibility of implementing a flywheel regenerative braking system in bicycles as a method to enhance energy efficiency in transportation.

Get Price

Flywheel energy storage

OverviewMain componentsPhysical characteristicsApplicationsComparison to electric batteriesSee alsoFurther readingExternal links

A typical system consists of a flywheel supported by rolling-element bearing connected to a motor–generator. The flywheel and sometimes motor–generator may be enclosed in a vacuum chamber to reduce friction and energy loss. First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors

Get Price

Flywheel Energy Storage with Mechanical Input-Output for

For braking, a cable winds onto a pulley geared to the vehicle''s propulsion driveshaft as it unwinds from another pulley geared to the flywheel and then operates in reverse for the

Get Price

More related information

-

Flywheel energy storage vehicle power supply method

Flywheel energy storage vehicle power supply method

-

Motor flywheel energy storage

Motor flywheel energy storage

-

Which flywheel energy storage company is the largest

Which flywheel energy storage company is the largest

-

Does flywheel energy storage increase in speed as it is stored

Does flywheel energy storage increase in speed as it is stored

-

Pakistan flywheel energy storage equipment

Pakistan flywheel energy storage equipment

-

Calculation of power consumption of flywheel energy storage equipment

Calculation of power consumption of flywheel energy storage equipment

-

Dominican flywheel energy storage photovoltaic power generation outdoor unit

Dominican flywheel energy storage photovoltaic power generation outdoor unit

-

Flywheel Energy Storage Wheel

Flywheel Energy Storage Wheel

Commercial & Industrial Solar Storage Market Growth

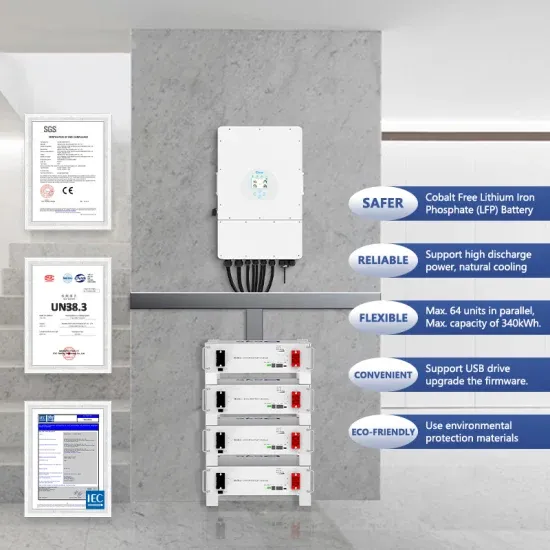

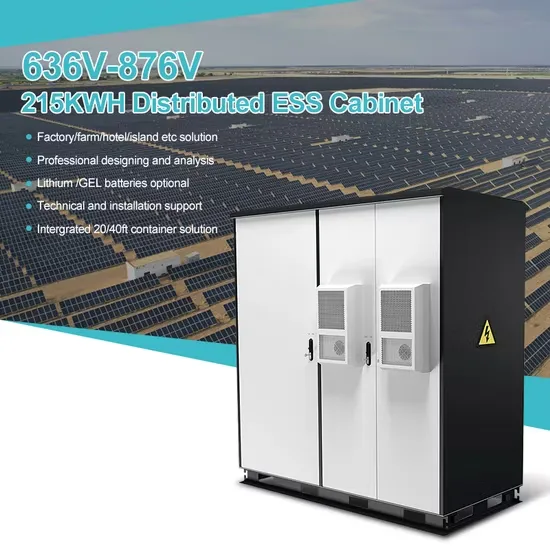

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.