Types of High-Temperature Batteries and Their

High-Temperature LFP battery packs are typically categorized into five levels based on their operating temperatures: 100°C, 125°C, 150°C, 175°C, and above 200°C.

Get Price

High Temperature Battery: What You Need to Know

High temperature batteries can operate effectively at temperatures exceeding 200°C, while regular lithium-ion batteries typically function best

Get Price

Thermal management requirements in battery packs: An analysis

According to this framework, the thermal behaviour and management requirements of battery packs under different states of health (SOH) were analysed.

Get Price

UL-Certified Battery Pack Interconnect System for Commercial Evs

UL-Certified Battery Pack Interconnect System for Commercial Evs - High Temp Resistance Hv Cable Wiring Harness Assembly Tyco 4-2208102-1 L=1m, Find Details and Price about 2

Get Price

Battery Pack Thermal Design

How best to test the design? 4. Adhesive/glue. The cell only vented with a max measured cell surface temperature less than 138oC.

Get Price

The Ultimate Guide to Selecting NTC,PTC and thermal switches

When the surrounding temperature increases beyond the design threshold, the PTC''s resistance rises sharply, reducing the current flow in the circuit. This limits overheating

Get Price

Battery Pack Requirements for EV Safety & Performance

Battery packs are the heart of electric vehicles, but what goes into making a safe and reliable one? This article explores the various requirements that battery packs need to meet.

Get Price

High Temperature Battery: What You Need to Know

High temperature batteries can operate effectively at temperatures exceeding 200°C, while regular lithium-ion batteries typically function best between 0°C and 60°C.

Get Price

Large-capacity temperature points monitoring of lithium-ion battery

Excessive temperature may cause a series of side reactions inside the battery, which in turn triggers the thermal runaway of the battery and ultimately leads to serious safety

Get Price

Types of High-Temperature Batteries and Their

High-Temperature LFP battery packs are typically categorized into five levels based on their operating temperatures: 100°C, 125°C, 150°C,

Get Price

General Requirements for LiFePO4 Battery Matching

LiFePO4 Battery Matching Overview LiFePO4 battery matching involves combining multiple cells into a single battery pack. Below are the

Get Price

How does temperature affect the performance of a high

High temperature battery packs are used in a variety of applications, each with its own unique temperature requirements. For instance, in downhole operations, batteries are exposed to

Get Price

Battery Pack Requirements for EV Safety & Performance

Battery packs are the heart of electric vehicles, but what goes into making a safe and reliable one? This article explores the various requirements that battery

Get Price

Technical specifications and test protocols for the battery

iver two 12kWh-demonstrator battery packs at TRL6 and MRL8. These aim at demonstrating the 3beLiEVe technology performance for applications in light duty (i.e. passenger cars, freight

Get Price

Battery Certification-Your Expert Guide for Battery Safety

As a custom battery pack expert, our battery packs are designed and undergo rigorous testing to meet diverse needs of battery applications

Get Price

Addressing BMS Battery Pack Current and Voltage

Learn about battery pack current measurement and analog-to-digital converters (ADCs) requirements within battery management systems (BMSs).

Get Price

Thermal assessment of lithium-ion battery pack system with heat

In experiments, the temperature may be high due to an increase in electrical resistance as the battery reaches the end of its SOC, as connection resistance and a non

Get Price

High-Voltage Copper/Aluminum Busbars in Battery Packs (III):

Currently, the widespread adoption of 800V high-voltage platforms in new energy vehicles has made the copper/aluminum busbars within battery packs critical components.

Get Price

The Ultimate Guide to Selecting NTC,PTC and

When the surrounding temperature increases beyond the design threshold, the PTC''s resistance rises sharply, reducing the current flow in the

Get Price

12V 3200mAh NiMH Battery Pack – High Temp 70°C

Nominal Voltage 12V Nominal Capacity 3200mAh Energy 38.4Wh Designed for demanding applications, this 12V 3200mAh NiMH battery pack delivers

Get Price

Comprehensive Guide to IP Waterproof Ratings li ion

Learn IP waterproof ratings (IP67, IP68, IP69K) for lithium battery packs. Find differences and how to choose the best level for application.

Get Price

How does temperature affect the performance of a high temperature

High temperature battery packs are used in a variety of applications, each with its own unique temperature requirements. For instance, in downhole operations, batteries are exposed to

Get Price

A Guide to Understanding Battery Specifications

Battery Basics Cell, modules, and packs – Hybrid and electric vehicles have a high voltage battery pack that consists of individual modules and cells organized in series and parallel. A cell is the

Get Price

Monitoring EV Battery Temperature Using Thermal Imaging

1. Infrared Sensor Arrays and Meshes Embedded in Battery Packs Thermal management in electric vehicle battery systems presents unique challenges due to the high

Get Price

Battery Pack Manufacturing Process

The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are grouped into modules. This stage

Get Price

Electric Vehicle Battery Packs

SABIC''s Specialties business ofers a range of solutions with safety and functionality in mind. Our experts have a longstanding tradition of tailoring specialty solutions to meet demanding

Get Price

A Comprehensive Approach to Battery Module and Pack Testing

Temperature is a critical factor affecting battery performance, safety, and longevity. Thermal testing simulates extreme operating environments to determine how well battery modules and

Get Price

Automotive Battery Pack Standards and Design Characteristics:

This review aims to bridge the gap between academic research and industry requirements by providing a structured analysis of automotive battery pack standards, key

Get Price

Over 85°C High Temperature Battery Pack Solution

CMB is committed to advancing battery pack technology. Our heat-resistant battery maintains a 1C discharge rate even at temperatures of 85°C, thanks to innovative design and high

Get Price

6 FAQs about [Pack battery high temperature resistance requirements]

What is a high-temperature battery pack?

When your devices work outdoors in winter and summer, our high-temperature battery pack can be discharged and charged for a long time at low temperatures below zero and high temperatures over 60°C. Our high-temperature battery packs are ideal for replacing the current standard 18650 and 21700 battery packs.

What is a high temperature LFP battery pack?

High-Temperature LFP battery packs are typically categorized into five levels based on their operating temperatures: 100°C, 125°C, 150°C, 175°C, and above 200°C.

What temperature should a battery pack be tested at?

Capacity test at different temperatures and discharge ratesFor high-power battery packs and systems, the test has to be performed at three different temperatures (40 °C, 0 °C and −18 °C) with the discharge rates 1C,

What temperature does a high temperature battery work?

High temperature batteries can operate effectively at temperatures exceeding 200°C, while regular lithium-ion batteries typically function best between 0°C and 60°C. What industries primarily use high temperature batteries?

What is a high-temperature battery cell?

The profile of our high-temperature battery cell is 18650 cylindrical, assembled as a high-temperature 18650 battery pack. When your devices work outdoors in winter and summer, our high-temperature battery pack can be discharged and charged for a long time at low temperatures below zero and high temperatures over 60°C.

What is a high-temperature rechargeable lithium battery?

At CM Batteries, Our high-temperature rechargeable Lithium battery packs are renowned for their exceptional reliability, 1500 cycles from -40°C to +85°C, providing lasting power for your innovative devices. The profile of our high-temperature battery cell is 18650 cylindrical, assembled as a high-temperature 18650 battery pack.

More related information

-

Lifespan of high temperature lithium battery pack

Lifespan of high temperature lithium battery pack

-

Polish wide temperature lithium titanate battery pack

Polish wide temperature lithium titanate battery pack

-

Energy storage cabinet battery high temperature

Energy storage cabinet battery high temperature

-

High capacity lithium battery pack customization

High capacity lithium battery pack customization

-

High energy compressed lithium battery pack

High energy compressed lithium battery pack

-

Belize Outdoor Communication Battery Cabinet High and Low Temperature 2 2KWH

Belize Outdoor Communication Battery Cabinet High and Low Temperature 2 2KWH

-

380v high voltage lithium battery pack

380v high voltage lithium battery pack

-

New energy battery cabinet high temperature

New energy battery cabinet high temperature

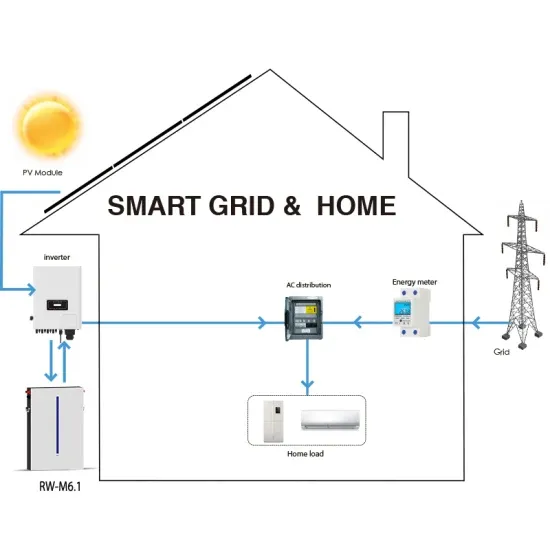

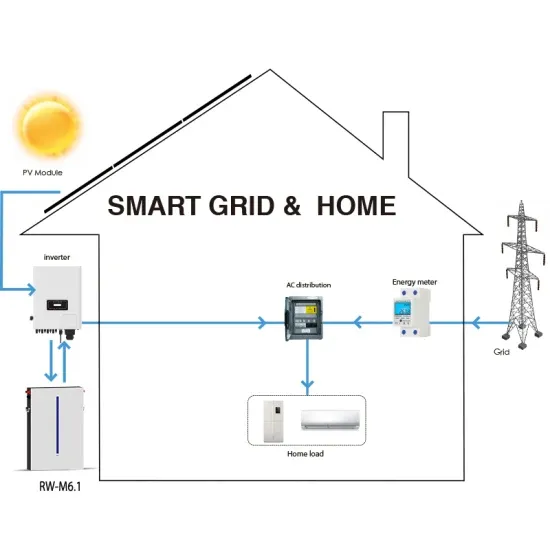

Commercial & Industrial Solar Storage Market Growth

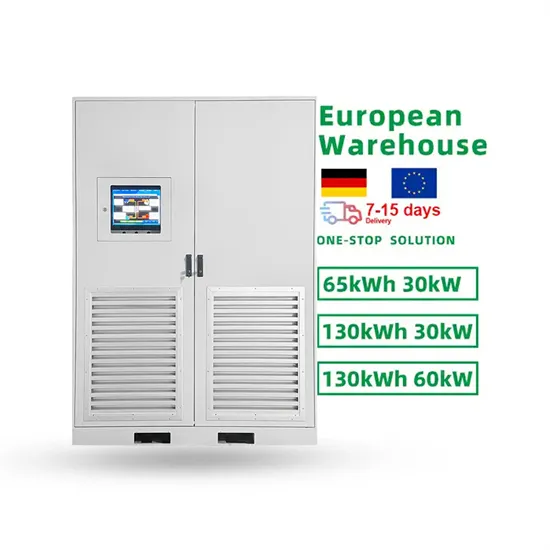

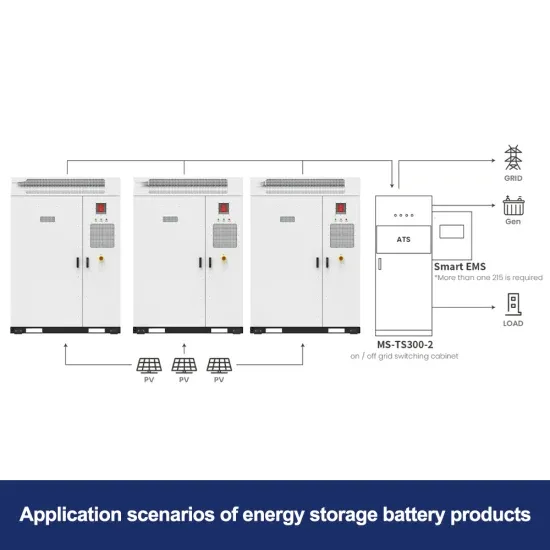

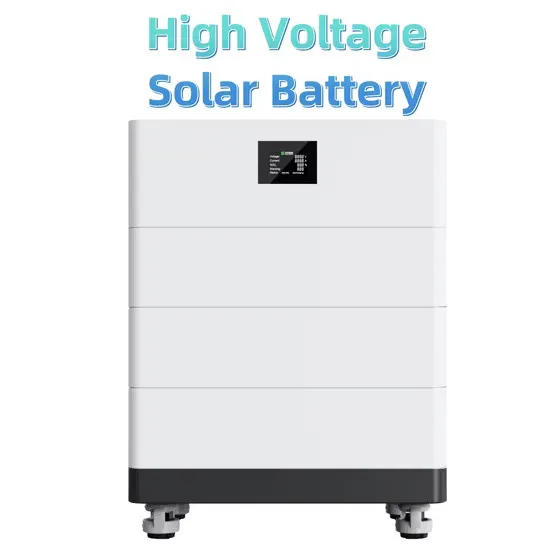

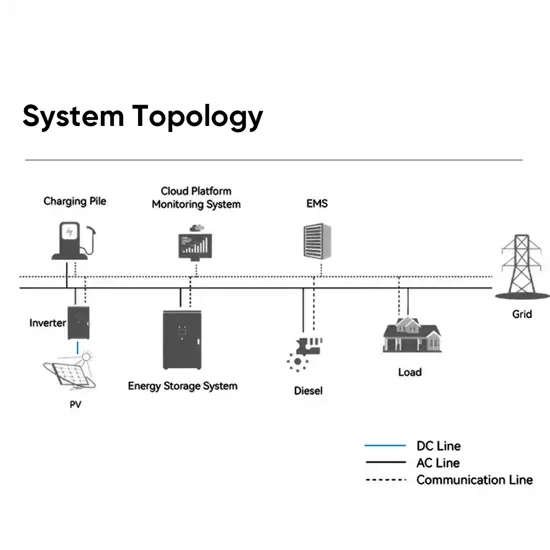

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.