Frequently Asked Questions about Inverters

There is a simple method to calculate how much power your inverter is using: For 12-volt inverters, divide the connected load by 10; for 24-volt inverters, divide by 20.

Get Price

Battery Runtime Calculator | How Long Can A Battery

Use Battery Runtime Calculator to Calculate runtime of your battery. Learn how long can a battery last. Good for solar and car battery

Get Price

Matching inverter to battery

I don''t see where this is discussed much at all. Say I have a 2000 watt inverter with a load pulling 2000 watts at 120 volts AC. That would mean I am pulling 16.6 amps AC from

Get Price

How much power does an Inverter use just sitting there idling?

Hello, Quick question. I have a 24V 3000W pure sine wave inverter powering two 15A circuits. The inverter itself uses about 30W running a 500W load. There are some times

Get Price

Inverter Capacity Calculator & Formula Online Calculator Ultra

Can I use an inverter with a higher capacity than needed? Yes, but it might lead to inefficiencies and higher costs without additional benefits. This calculator assists users in

Get Price

Power Inverter Calculator | Watt Calculator | Go Power!

Which power inverter is right for you? By answering these simple questions, we can recommend a product for you in just a few moments. This calculator helps us identify how much power your

Get Price

RV Solar Power Blue Prints

It can handle any solar panel array up to 4000 watts, can handle a large battery bank of 24/12/6 batteries wired to 24 volts, and can power a large 24 volt

Get Price

Lithium (LiFePO4) Battery Runtime Calculator

Calculating battery runtime on a load can be confusing for some folks. We created a lithium battery runtime/life calculator for your ease.

Get Price

What Will An Inverter Run & For How Long? (With Calculator)

So a simple rule will be to minimize 15% of your inverter''s full capacity in order to get the maximum number of watts you can run with your inverter. For example: Let''s take a

Get Price

How Long Does A 24 volt Battery Last? (incl.

In simple wording --- voltage = pressure. We measure the total energy in watts. And the formula for watts = voltage × amps. 12V vs 24V

Get Price

Inverter Amp Draw Calculator: Let''s Simplify It

Our inverter amp draw calculator will help you determine the amps being pulled from your inverter to avoid depletion.

Get Price

Calculate Battery Size For Any Size Inverter (Using

So I have made it easy for you, use the calculator below to calculate the battery size for 200 watt, 300 watt, 500 watt, 1000 watt, 2000

Get Price

Calculate How Long Will a 24V Battery Last – PowMr

The article explains how long will a 24V battery last, providing formulas and factors affecting battery runtime estimations.

Get Price

Inverter Amp Draw Calculator

Inverters with a greater DC-to-AC conversion efficiency (90-95%) draw fewer amps, whereas inverters with a lower efficiency (70-80%) draw more current. Note: The results

Get Price

Inverter Amp Draw Calculator

Inverters with a greater DC-to-AC conversion efficiency (90-95%) draw fewer amps, whereas inverters with a lower efficiency (70-80%) draw

Get Price

Inverter Size Calculator | Find Your Perfect Power Match

The inverter size calculator takes the guesswork out of choosing the right inverter. Simply select your appliances below, and you''ll instantly see the inverter size you need.

Get Price

What size inverter do I need for a refrigerator?

You could run most refrigerators using a 1500-watt pure sine wave inverter. Inverters of this size and type can consistently supply 1500 Watts of

Get Price

Does a 24V inverter consume the same amount of wattage as a 12V inverter?

An inverter seen from the terminals of the battery pack (however it is arranged, 12V, 24V, etc.) will look as a constant power load, i.e. as a two-terminal device that always

Get Price

How much power does an Inverter use just sitting there idling?

In the tech data, I''m supposed to give the inverter a "few seconds" before applying a load, so you could probably figure a way to do that. I''m sure applying the load while

Get Price

What Size Inverter Do You Need? A Complete Guide

Recommended models: RS-V2P12 – 12V 2000W Pure Sine Wave Inverter RS-V3P24 – 24V 3000W Pure Sine Wave Inverter * Lithium batteries

Get Price

Calculate Battery Size For Any Size Inverter (Using Our Calculator)

So I have made it easy for you, use the calculator below to calculate the battery size for 200 watt, 300 watt, 500 watt, 1000 watt, 2000 watt, 3000 watt, 5000-watt inverter

Get Price

12 Volt Battery Run Time Calculator

BatteryStuff Tech 17 watts / 12.5 volts = 1.36 amps. 9 of these lights will pull 12.24 amps per hour. running 8 hours is a total of 97.92 amps. The calculator recommend a battery

Get Price

How Many Amps Does a 2000W Inverter Draw?

A 12V 2000W inverter running at maximum load draws 166.6 amps an hour. Divide the watts consumed per hour by the voltage and you get the amps. In

Get Price

What Size Inverter Do I Need?

Finding the proper inverter size for your needs is as simple as adding together the necessary wattages of the items that you''re looking to power.

Get Price

What Can A 150W Inverter Run? (Explained!)

What can a 150W inverter run? The "150-watt" specification indicates the maximum power output capacity of the inverter. In simpler terms, it means that the inverter can power a

Get Price

6 FAQs about [Can a 24v inverter handle 850 watts ]

How much power does an inverter need?

The continuous power requirement is actually 2250 but when sizing an inverter, you have to plan for the start up so the inverter can handle it. Third, you need to decide how long you want to run 2250 watts. Let’s say you would like to power these items for an eight-hour period.

How much battery does a 24 volt inverter use?

For 24-volt inverters, it is 10 %. The battery capacity for a 12-volt Mass Sine 12/1200, for instance, is 240 Ah, while a 24-volt Mass Sine 24/1500 inverter would require at least 150 Ah. The indicated battery capacity is only for the inverter. The capacity required for other loads should be added to it. How much power does an inverter consume?

How to choose a power inverter?

Second, select an inverter. For this example, you will need a power inverter capable of handling 4500 watts. The continuous power requirement is actually 2250 but when sizing an inverter, you have to plan for the start up so the inverter can handle it. Third, you need to decide how long you want to run 2250 watts.

How much power does a 12V inverter use?

For example: If you're running a 1500W inverter on your 12v battery with 1000 watts of total AC load. So your inverter will be consuming 83 amps (amps = watts/battery volts) from the battery for which you'll need a very thick cable. using a thin cable in this scenario can damage the inverter or you'll not be able to run your load.

How many watts can a 3000-watt inverter run?

A rule of thumb is that the total output load should be less than the inverter capacity. For example, if you have a 3000-watt inverter you can run up to 2500 watts of output load with it. As I have mentioned earlier you have to keep in mind the efficiency rate of your inverter before putting the load on it. That is all you need to know.

How much power does a high frequency inverter use?

High frequency MOSFET drive switching is usually the dominate idle consumption but a poorly designed output PWM low pass filter can add to idle losses by having a high reactive power factor load. Generally a 3 kW sinewave high freq inverter is 30 to 50 watts of full idle power. A high frequency inverter has two primary stages.

More related information

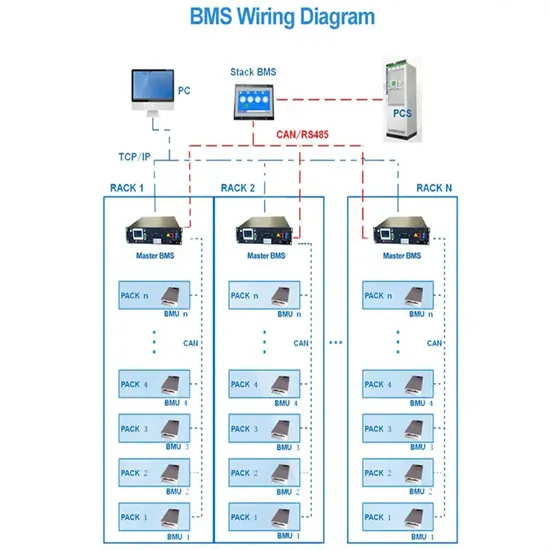

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

How many watts does a 24V to 220V inverter have

How many watts does a 24V to 220V inverter have

What is the minimum size of a 24v inverter

What is the minimum size of a 24v inverter

Can a 24v inverter be used with a 12v voltage

Can a 24v inverter be used with a 12v voltage

Italian 24v inverter

Italian 24v inverter

Inverter 9612v 24v universal 3kw

Inverter 9612v 24v universal 3kw

24v 120a inverter

24v 120a inverter

Uruguay 24v off-grid inverter

Uruguay 24v off-grid inverter

Is the 24v inverter durable

Is the 24v inverter durable