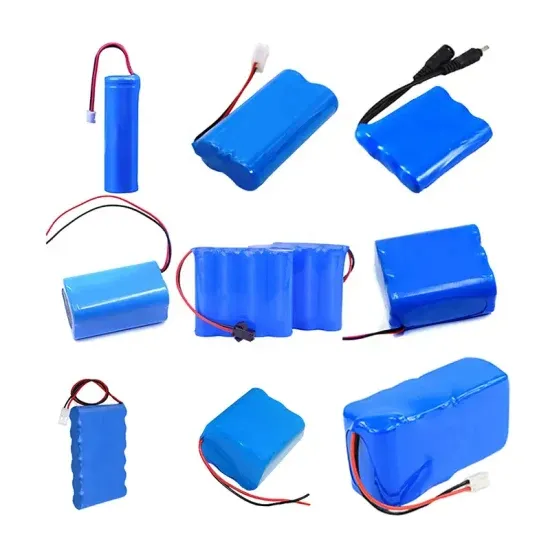

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent

Get Price

Lithium-ion Battery Module and Pack Production Line

The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and

Get Price

From Raw Materials to Finished Product: The Lithium

Manufacturing lithium ion batteries is a complex procedure that involves a lot of activity. The lithium battery manufacturing process—required

Get Price

The Complete Guide to Lithium Ion Battery Packaging

When shipping lithium ion batteries, government regulations will heavily dictate what packaging materials you use. According to the DOT,

Get Price

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering

Get Price

Lithium-ion Battery Module and Pack Production Line Process Flow

The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and rigorous process flow ensure

Get Price

Lithium-ion Battery Pack Manufacturing Process & Design

At the heart of the battery industry lies an essential lithium-ion battery assembly process called battery pack production.

Get Price

LITHIUM-ION

A major difference between lead-acid and lithium-ion batteries in industrial vehicle use is that with lithium-ion batteries, three-shift operation can be managed with a single installed battery,

Get Price

Safely shredding the largest EV battery packs in one

For industry professionals that need to safely and efficiently reclaim valuable materials from even the largest EV battery packs to increase

Get Price

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get Price

Understanding Global Lithium Battery Standards and

Home » Blog » Battery knowledge » Understanding Global Lithium Battery Standards and Certifications Lithium batteries power our everyday

Get Price

Battery Factory How to Build the Lithium-Ion Battery Pack?

The basic process of custom lithium battery packs is that after the battery specifications and samples meet the customer''s customized lithium-ion battery needs and are

Get Price

PRODUCTION PROCESS OF A LITHIUM-ION BATTERY

The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode manufacturing and

Get Price

KOBALT

Should that occur, the buyer is responsible for the invoice plus all fees associated with the legal process including but not limited to attorney''s fees, filing fees, court costs,

Get Price

Key Points of Lithium Battery PACK Manufacturing

Curious about how lithium batterypacks are made? Dive into the detailed process behind these essential energy storage solutions! From

Get Price

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get Price

The Complete Guide to Lithium Ion Battery Packaging

When shipping lithium ion batteries, government regulations will heavily dictate what packaging materials you use. According to the DOT, lithium ion batteries must be

Get Price

Requirements for a Process to Remanufacture EV

In case of electric vehicles (EV) powered by lithium ion traction batteries (LIB), remanufacturing processes nbecome increasingly important

Get Price

Lithium Batteries: Safety, Handling, and Storage

Lithium Cell Types Battery technology has seen very rapid development, with a proliferation of different technologies and types of batteries, in terms of construction and materials used. It is

Get Price

How to Repair an Electric Bike Battery: Everything You Need to

3 days ago· Because lithium-ion packs present fire and chemical risks, professional diagnosis and safe handling are crucial when cells or the Battery Management System (BMS) are

Get Price

The composition, method and parameter analysis of

The battery PACK needs to be used under specific conditions, including charging and discharging currents, charging methods, and

Get Price

SAFE OPERATING PROCEDURE Lithium Battery Storage

Every employer must ensure that all employees who handle lithium-ion batteries for their work or use equipment, or machines with batteries, know the basic rules. The intent of this SOP is to

Get Price

PRODUCTION PROCESS OF BATTERY MODULES AND

Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain. Overview of the production sequence from cell to system. 60% 80%

Get Price

Lithium Battery Pack Process: Assembly, Management and

The pack technology of lithium battery involves the assembly, management and future innovation and development of battery monomer. This article will focus on the key links, technological

Get Price

Sustainable manufacturing practices for EV battery packs:

Present-day approaches to creating EV battery packs are performed often with the help of restricted and hazardous materials and energy-demanding methods, having a rather

Get Price

PRODUCTION PROCESS OF BATTERY MODULES AND

"Production process of lithium-ion battery cells", this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series

Get Price

Li-ion Battery Pack Balance

The meaning of battery balance is to keep the voltage of the lithium-ion battery cell or the voltage deviation of the battery pack within the expected range. So

Get Price

From Raw Materials to Finished Product: The Lithium Batteries

Manufacturing lithium ion batteries is a complex procedure that involves a lot of activity. The lithium battery manufacturing process—required for each cell—includes lengthy,

Get Price

6 FAQs about [Pack lithium battery processing needs to be responsible]

Why should you choose a lithium-ion battery module & pack line?

The whole system has no leakage of electricity, water, liquid or gas, which ensures the safety and stability of the production process. The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and rigorous process flow ensure high quality and efficiency in production.

What is a lithium-ion battery module & pack production line?

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment that work in concert to achieve high quality lithium-ion module and pack production.

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

Do lithium ion batteries need packaging regulations?

Lithium ion batteries, essential for a multitude of devices and applications, are subject to stringent packaging regulations set by the U.S. Department of Transportation (DOT).

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

How are lithium ion batteries packaged?

Each battery or cell must be entirely enclosed to prevent contact with other equipment or any conductive materials. The inner packaging containing lithium ion batteries can be placed in containers crafted from various materials, including metal, wood, fiberboard, or solid plastic jerrycans.

More related information

-

Polish lithium battery pack processing manufacturer

Polish lithium battery pack processing manufacturer

-

Dominican lithium battery pack processing factory

Dominican lithium battery pack processing factory

-

Turkmenistan large-cell lithium battery pack

Turkmenistan large-cell lithium battery pack

-

Solar lithium battery pack prices in Equatorial Guinea

Solar lithium battery pack prices in Equatorial Guinea

-

Ladder use of lithium iron phosphate battery pack

Ladder use of lithium iron phosphate battery pack

-

25 2v 2a lithium battery pack

25 2v 2a lithium battery pack

-

Laos lithium battery pack

Laos lithium battery pack

-

Rwanda pack battery processing

Rwanda pack battery processing

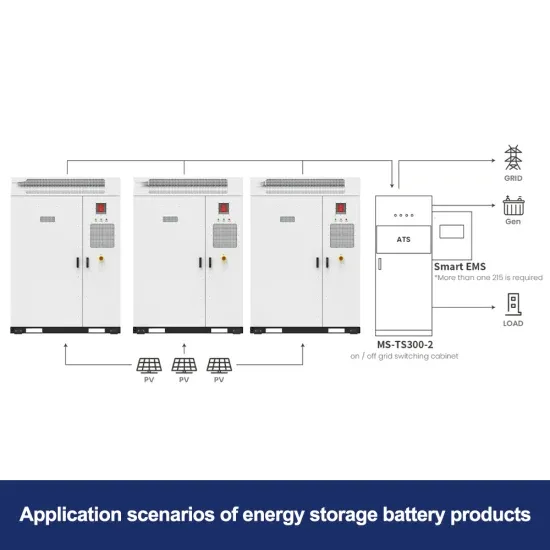

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

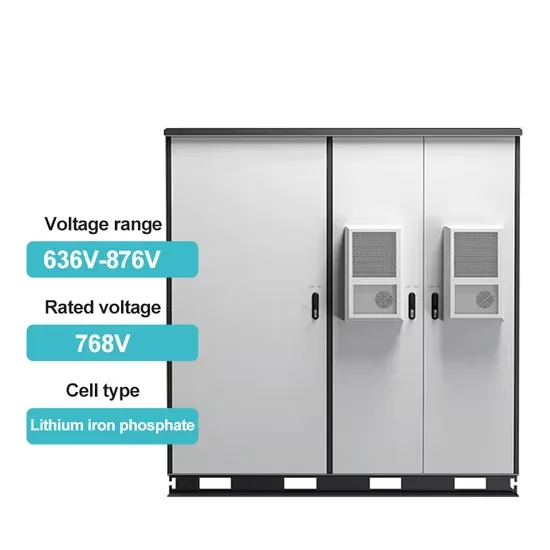

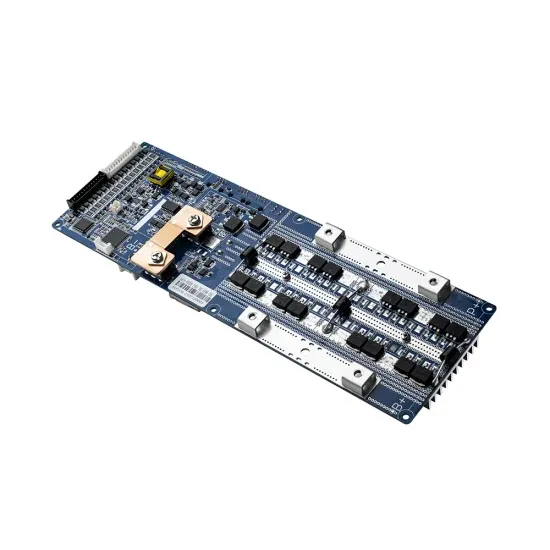

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.