Comprehensive Analysis of Thermal Dissipation in Lithium-

ABSTRACT e compact designs and varying airflow conditions present unique challenges. This study investigates the thermal performance of a 16-cell lithium-ion battery pack by optimizing

Get Price

New Huawei graphene heat dissipation could make

It seems like Huawei has found a new graphene heat dissipation tech to usher a major change in its smartphone weight and battery capacity.

Get Price

Why do we have heating and cooling elements in a battery pack?

Cooling elements in battery packs rely on heat transport mechanisms such as radiation, conduction, and convection. An effective design maximizes these methods to

Get Price

Comprehensive Analysis of Thermal Dissipation in Lithium-

ABSTRACT Effective thermal management is critical for lithium-ion battery packs'' safe and efficient operations, particularly in applications such as drones, where compact designs and

Get Price

Heat dissipation investigation of the power lithium-ion battery

In this work, simulation model of lithium-ion battery pack is established, different battery arrangement and ventilation schemes are comparatively analyzed, effects of different

Get Price

Comprehensive Analysis of Thermal Dissipation in Lithium-Ion Battery Packs

This study investigates the thermal performance of a 16-cell lithium-ion battery pack by optimizing cooling airflow configurations and integrating phase change materials

Get Price

Heat dissipation design for lithium-ion batteries

A two-dimensional, transient heat-transfer model for different methods of heat dissipation is used to simulate the temperature distribution in lithium-ion batteries. The

Get Price

Comprehensive Analysis of Thermal Dissipation in Lithium-Ion

This study investigates the thermal performance of a 16-cell lithium-ion battery pack by optimizing cooling airflow configurations and integrating phase change materials

Get Price

Thermal assessment of lithium-ion battery pack system with heat

The aim is to effectively manage battery temperatures, thereby reducing manufacturing and operational costs. An innovative heat generation model was designed

Get Price

Comparison of cooling methods for lithium ion battery pack heat

At present, the common lithium ion battery pack heat dissipation methods are: air cooling, liquid cooling, phase change material cooling and hybrid cooling. Here we will take a

Get Price

Heat Management in Lithium-Ion Batteries

Heat dissipation is the process by which heat is directed away from the battery, preventing it from reaching dangerous temperatures. This is essential in high

Get Price

Numerical research on lithium-ion battery thermal

To promote battery heat dissipation, a novel cobweb-like type (C-type) channel cooling plate with asymmetric inlet and outlet is designed.

Get Price

FusionSolar Residential ESS Intelligent Low-temperature Heating

They integrate Huawei''s proprietary BMS and intelligent heating algorithm to implement collaboration between cells, heating modules, and the BMS. With reduced heating energy

Get Price

How to calculate the heat dissipated by a battery pack?

The pack provides power to a motor which in turn drives the wheels of an EV. I wanted to design the cooling system for the battery pack, so wanted to know the heat

Get Price

Know Everything About the Battery pack heat

Heat generation in a battery occurs during charge and discharge due to enthalpy changes, electrochemical polarization and resistive heating

Get Price

Thermal characteristics and reliability analysis of liquid-cooled heat

For a long time, many scholars have been devoted to the research of the most advanced battery thermal management system (BTMS), and the current main heat dissipation

Get Price

The Heat Dissipation and Thermal Control Technology of Battery Pack

The heat dissipation and thermal control technology of the battery pack determine the safe and stable operation of the energy storage system. In this paper, the

Get Price

Liquid Cooling System

The liquid cooling system consists of the primary side and secondary side. The primary side includes the cooling tower and (optional) chiller. The secondary side includes a coolant

Get Price

How Does Lithium Battery Packaging Affect Heat Dissipation in

Understand the effects of lithium battery packaging on heat dissipation, comparing square, cylindrical, and pouch cells designs.

Get Price

The Heat Dissipation and Thermal Control Technology of Battery

The heat dissipation and thermal control technology of the battery pack determine the safe and stable operation of the energy storage system. In this paper, the

Get Price

Comparison of cooling methods for lithium ion battery

At present, the common lithium ion battery pack heat dissipation methods are: air cooling, liquid cooling, phase change material cooling and

Get Price

Environment Requirements

The operation and service life of the battery depend on the operating temperature. Install the battery at a temperature equal to the ambient temperature or in a better environment. The

Get Price

STUDY OF THERMAL CHARACTERISTICS OF LITHIUM

When assessing lithium-ion battery systems'' capacity for heat dissipation, key evaluation indicators include maximum and average temperature of battery pack and

Get Price

Review on Lithium-Ion Battery Heat Dissipation Based on

Review on Lithium-Ion Batery Heat Dissipation Based on Microchannel–PCM Coupling Technology Jun Chen 1, Wanli Xu 1, Hao Tian 1, Yichao Cao 2,3, Jincheng Gu 4, Haijun Zhou

Get Price

User Manual

Before transporting a faulty battery (with scorch, leakage, bulge, or water intrusion), insulate its positive and negative terminals, pack it, and place it in an insulated explosion-proof box as

Get Price

Solving Battery Heating Issues with Heat Transfer

Heat transfer simulation can help solve and prevent heating issues early in the battery design process. Learn more now with SimScale!

Get Price

6 FAQs about [Huawei pack battery heat dissipation form]

What is battery pack heat dissipation?

Battery pack heat dissipation, also called thermal management cooling technology plays a key role in this regard. It involves the transfer of internal heat to the external environment via a cooling medium, thereby reducing the internal temperature.

What are the different types of lithium ion battery pack heat dissipation?

At present, the common lithium ion battery pack heat dissipation methods are: air cooling, liquid cooling, phase change material cooling and hybrid cooling. Here we will take a detailed look at these types of heat dissipation. 1. Air cooling

Why is battery heat dissipation important?

Therefore, an effective battery heat dissipation system is important for improving the overall performance of the battery pack. At present, the common lithium ion battery pack heat dissipation methods are: air cooling, liquid cooling, phase change material cooling and hybrid cooling.

Can heat pipe be used to treat battery pack system with passive cooling?

Experimental results are also obtained for heat pipe on the battery lithium-ion cells that transport heat from battery cells to the heat sink to treat the battery pack system with passive cooling systems to look at the possibility of future production. .

How does air cooling work for lithium-ion battery packs?

Air cooling, mainly using air as the medium for heat exchange, cools down the heated lithium-ion battery pack through the circulation of air. This is a common method of heat dissipation for lithium-ion battery packs, which is favoured for its simplicity and cost-effectiveness. a. Principle

What is a fixed temperature condition for a battery pack?

The power generation from the battery pack is employed in Fluent from 0.5C to 10C for different ambient temperatures. The fixed temperature condition is considered for the heat sink side with the same ambient temperature, where the top and bottom walls are insulated (h = 0 W/m 2 K).

More related information

-

Energy storage lithium battery pack heat dissipation

Energy storage lithium battery pack heat dissipation

-

Huawei Zambia heat dissipation photovoltaic panels

Huawei Zambia heat dissipation photovoltaic panels

-

Heat dissipation type energy storage lithium battery station cabinet

Heat dissipation type energy storage lithium battery station cabinet

-

Huawei pack battery power consumption

Huawei pack battery power consumption

-

Battery cabinet air cooling system heat dissipation

Battery cabinet air cooling system heat dissipation

-

Huawei Slovakia pack lithium battery factory

Huawei Slovakia pack lithium battery factory

-

Cabinet battery energy storage and heat dissipation

Cabinet battery energy storage and heat dissipation

-

Energy storage battery cabinet heat dissipation

Energy storage battery cabinet heat dissipation

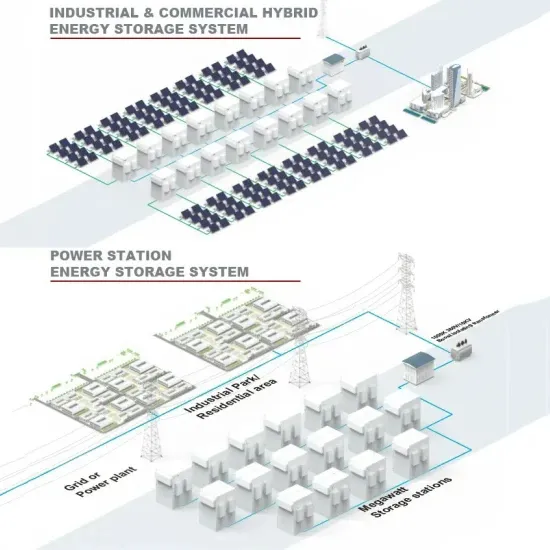

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.